Absorbent and absorbent article

An absorber and absorbent technology, which is applied in the direction of absorbent pads, etc., can solve the problems of insufficient absorption performance of the absorber, insufficient diffusion, discomfort, etc., and achieve good wearing feeling, increased absorption, and reduced sticky feeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

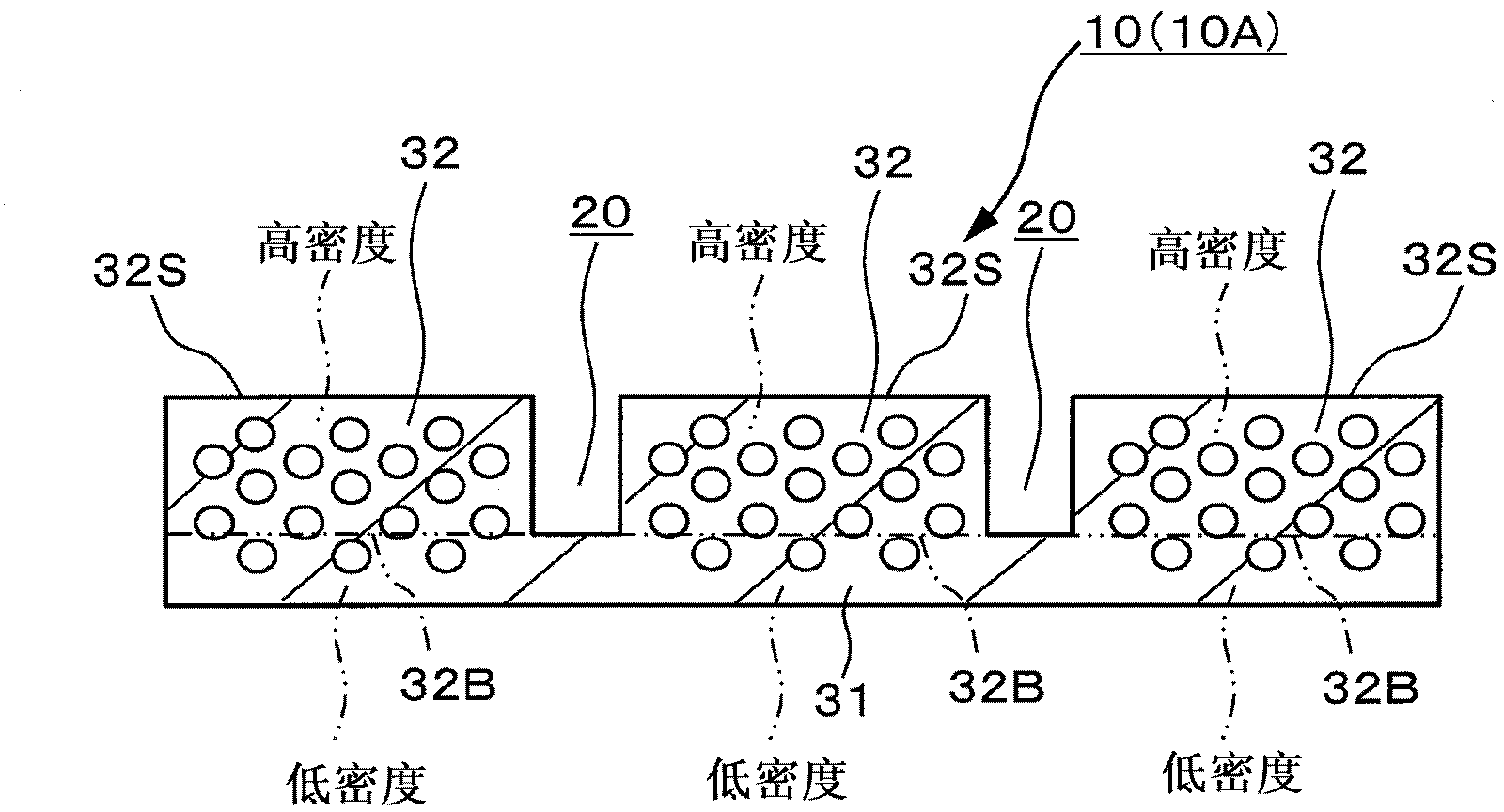

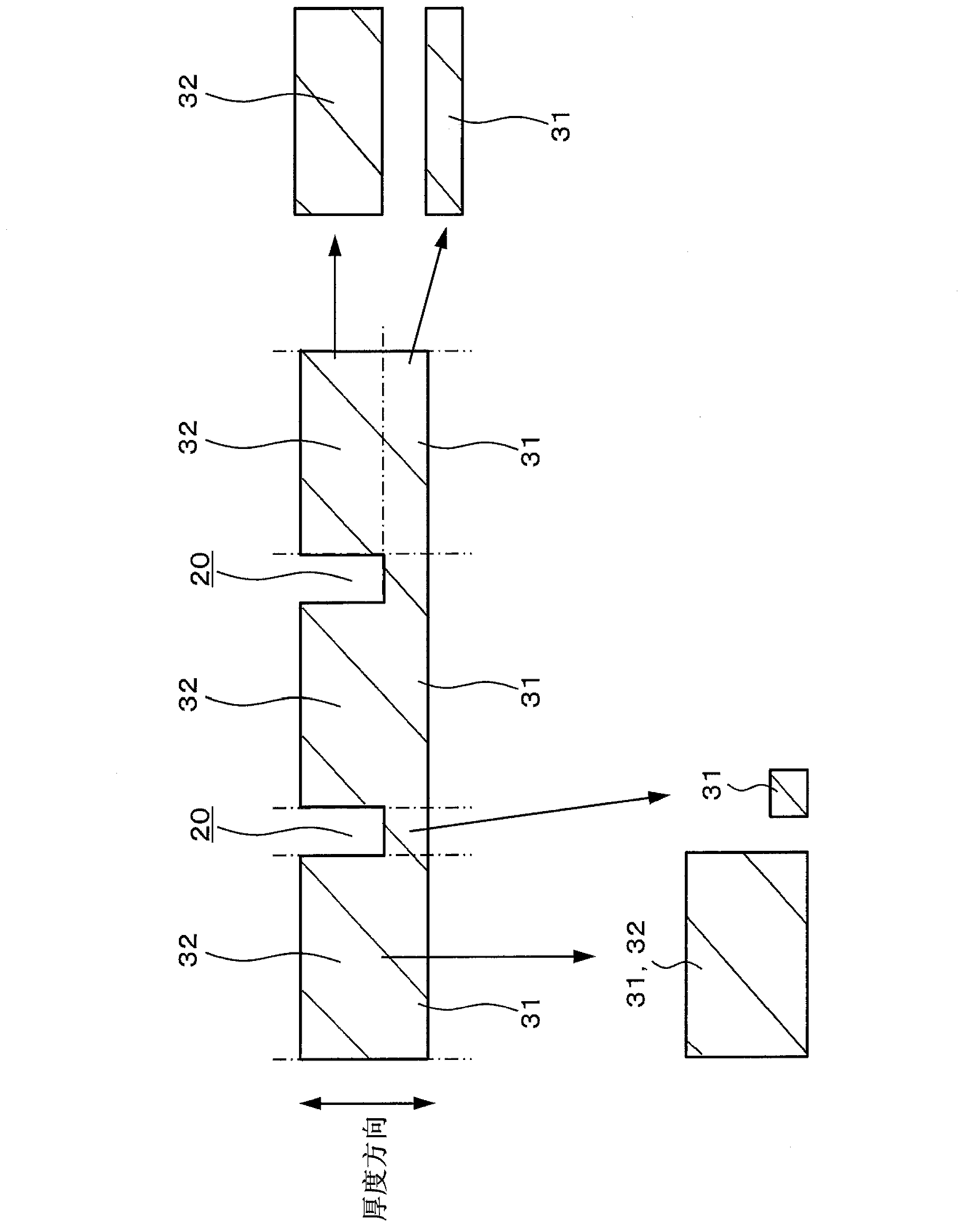

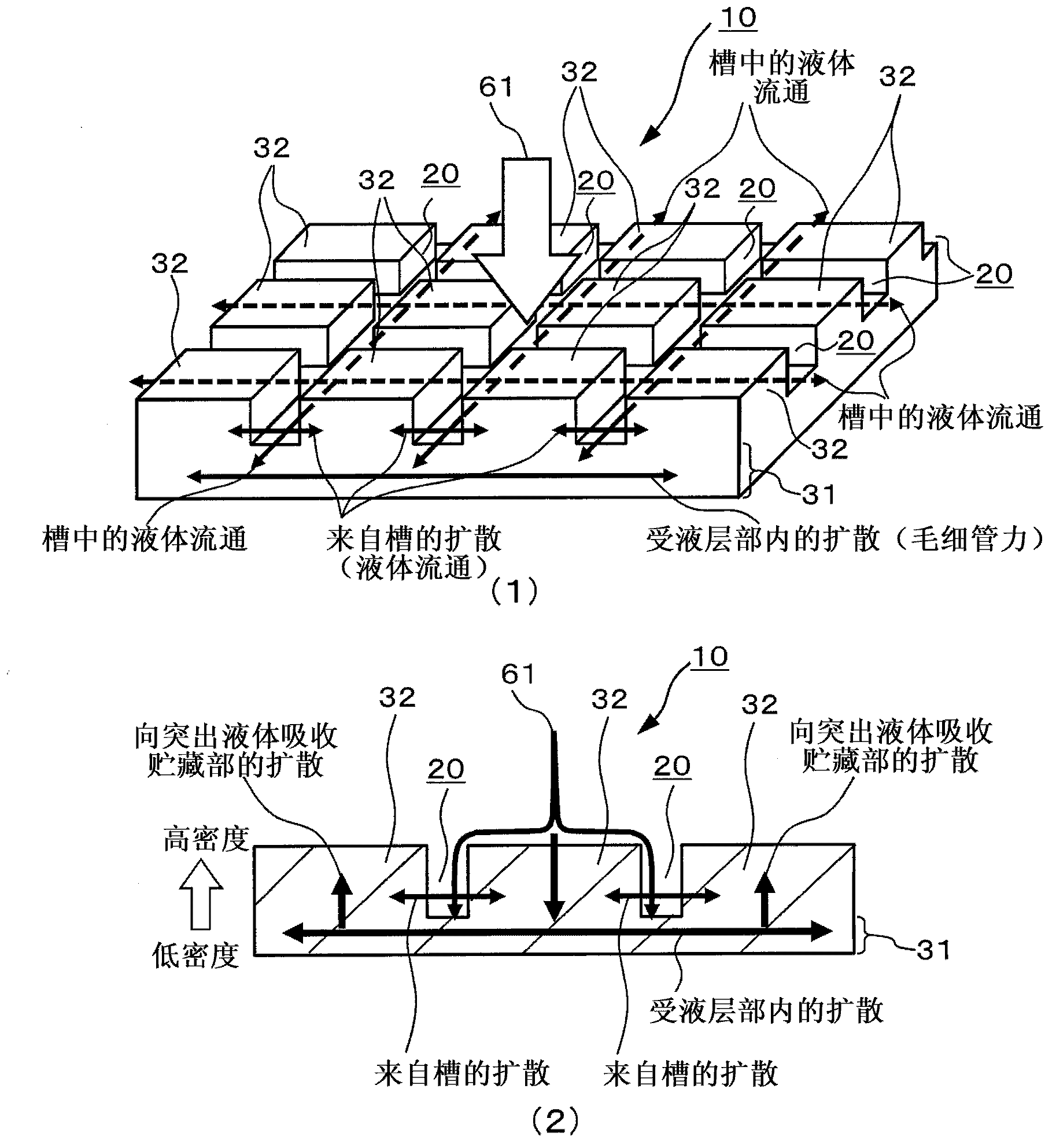

Embodiment 1

[0226] The absorber 10 of Example 1 was produced as follows. First of all, for the stack fiber cavity 107 with a depth of 6mm, to obtain Figure 26 Protrusions 108 with a height of 2 mm are configured in the shape shown in . The cross-sectional shape of the protrusion 108 is rectangular. Thereafter, fluff pulp (manufactured by Weyerhaeuser Co., Ltd., trade name NB416) and superabsorbent polymer (manufactured by Nippon Catalyst Co., Ltd., trade name W101) were deposited in the fiber stacking cavity 107 . At this time, the basis weight of the paper in the protruding liquid-absorbing storage part 32 is 200 g / m of pulp. 2 , superabsorbent polymer is 320g / m 2 , the paper weight of the liquid-receiving layer part 31 at the bottom of the concave part 20 is that the pulp is 50g / m 2 , superabsorbent polymer is 50g / m 2 . After stacking, the stacked absorbent body 10 was peeled off from the fiber stacking cavity 107, and pressed at a pressure of 0.025 MPa. The absorber 10 was reve...

Embodiment 2

[0228] The absorber 10 of Example 2 was produced by the same procedure as Example 1 except having set the height of the protrusion part 108 to 2 mm in the central part in the longitudinal direction of the absorber, and 1 mm in the outer part.

Synthetic example 1

[0267] In Synthesis Example 1, first, add Kao Co., Ltd. Sodium polyoxyethylene lauryl ether sulfate (trade name EMAL20C) was prepared at 0.11% [relative to the mass of acrylic acid], and 1600 mL of cyclohexane was added. The mixture was stirred under a nitrogen atmosphere, and the internal temperature was raised to 77°C.

[0268] On the other hand, 80% acrylic acid manufactured by Toagosei Co., Ltd. and ion-exchanged water were added to a 2-L three-necked flask, and 48% aqueous sodium hydroxide solution manufactured by Asahi Glass Co., Ltd. was added dropwise while cooling with ice to obtain a monomer aqueous solution. Sodium acrylate aqueous solution (72% neutralized product, concentration about 48%) 1054g. To this aqueous monomer solution, 0.18 g of N-acylated sodium glutamate (trade name AMISOFT GS-11F) produced by Ajinomoto Co., Ltd. was dissolved in 3 g of ion-exchanged water, stirred for a while, and divided into 264 g (hereinafter referred to as monomer aqueous soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water absorption | aaaaa | aaaaa |

| Absorption | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com