Stress control body for plastic insulation high-voltage and direct-current cable connector

A cable joint, high-voltage DC technology, applied in cable joints and other directions, can solve the problem of difficult to meet the connection requirements of plastic-insulated high-voltage DC cables above 160kV, achieve excellent uniform electric field distribution, reduce interface space charge, and high DC breakdown. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

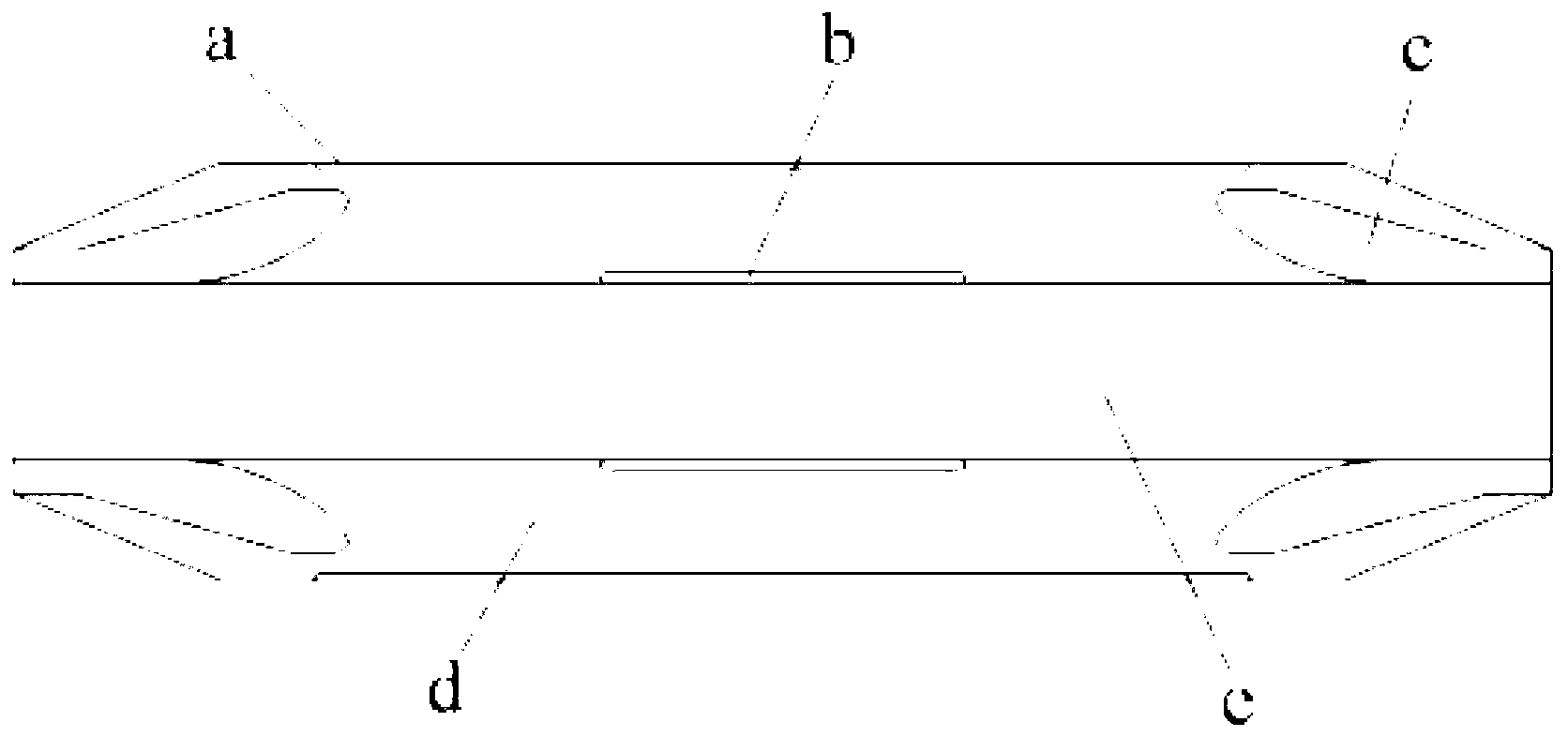

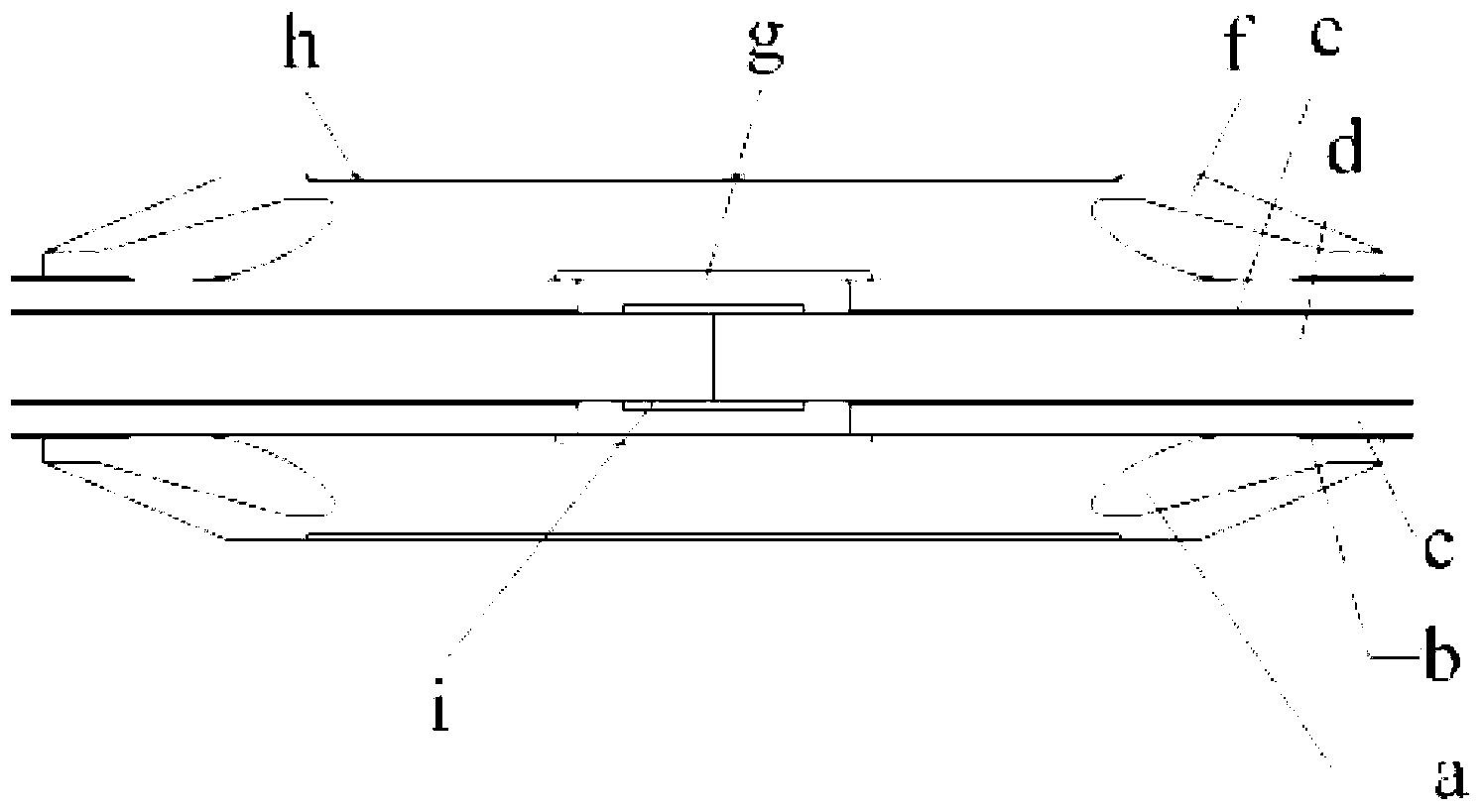

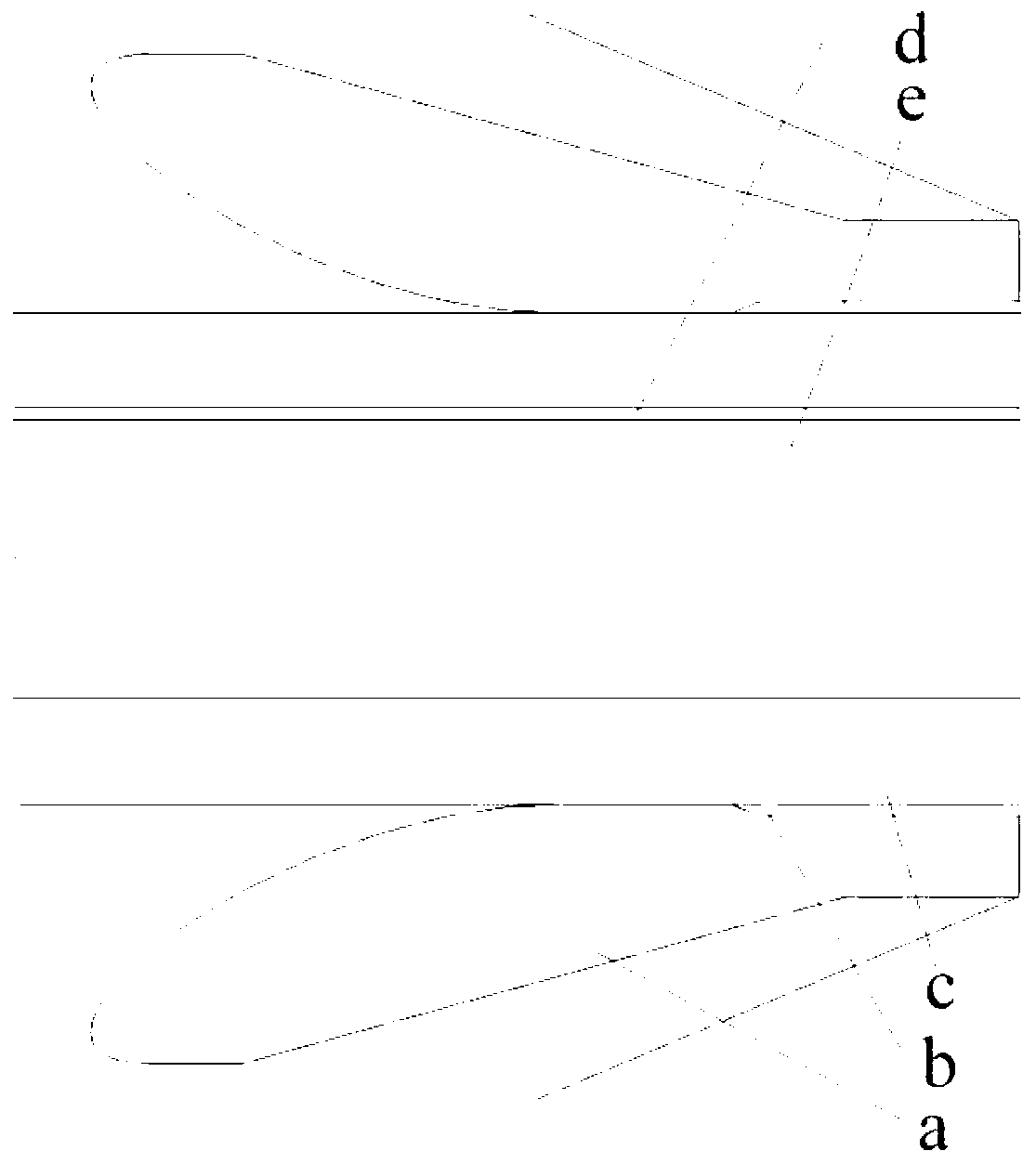

[0020] Specific implementation mode 1: A stress control body for plastic insulated high-voltage DC cable joints in this embodiment is a stress control body for 160kV-500kV XLPE insulated high-voltage DC cable joints, and the 160kV-500kV XLPE insulation The stress control body for the high-voltage DC cable joint is composed of a high-voltage shielding layer, a reinforced insulator, a stress cone and an outer shielding layer. The ports on both sides of the reinforced insulator are trapezoidal, and the reinforced insulator is made of a conductance nonlinear insulating material; The conductance non-linear insulating material is liquid silicone rubber-based conductance non-linear insulating material, mixed silicone rubber-based conductance non-linear insulating material or EPDM rubber-based conductance non-linear insulating material;

[0021] The liquid silicone rubber-based conductance nonlinear insulating material is made of 100 parts of liquid silicone rubber and 10 to 20 parts o...

specific Embodiment approach 2

[0030] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the organic peroxide is benzoyl peroxide, di-tert-butyl peroxide, dicumyl peroxide or 2,5-di Methyl-2,5-di-tert-butylperoxyhexane, and others are the same as in Embodiment 1.

specific Embodiment approach 3

[0031] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the liquid silicone rubber-based conductance nonlinear insulating material consists of 100 parts by weight of liquid silicone rubber, 10 parts of nano-zinc oxide, 2 parts of nano-titanium dioxide, 5 parts of nano-silicon carbide, 0.5 parts of carbon nanotubes, 0.5 parts of conductive carbon black and 0.5 parts of nano-graphite, and the others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com