Crystal direction finder for directly measuring deflecting angle in crystal orientation and measurement method thereof

A technology for measuring the deviation angle and crystal, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of cumulative error X-rays, complicated operation methods, and low measurement efficiency, so as to reduce the cumulative error and avoid the influence of human factors. The effect of avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The method for directly measuring the crystal orientation deviation angle of the present invention is characterized in that the steps are as follows:

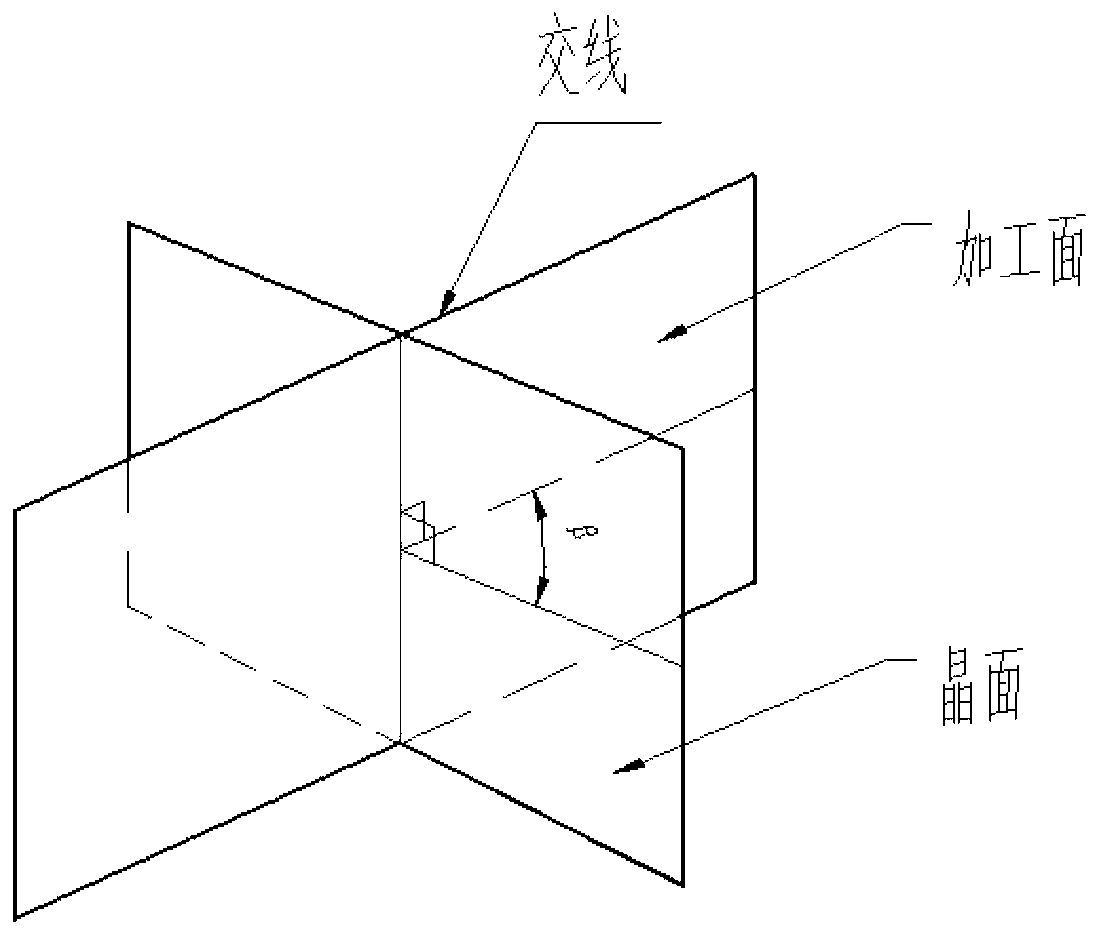

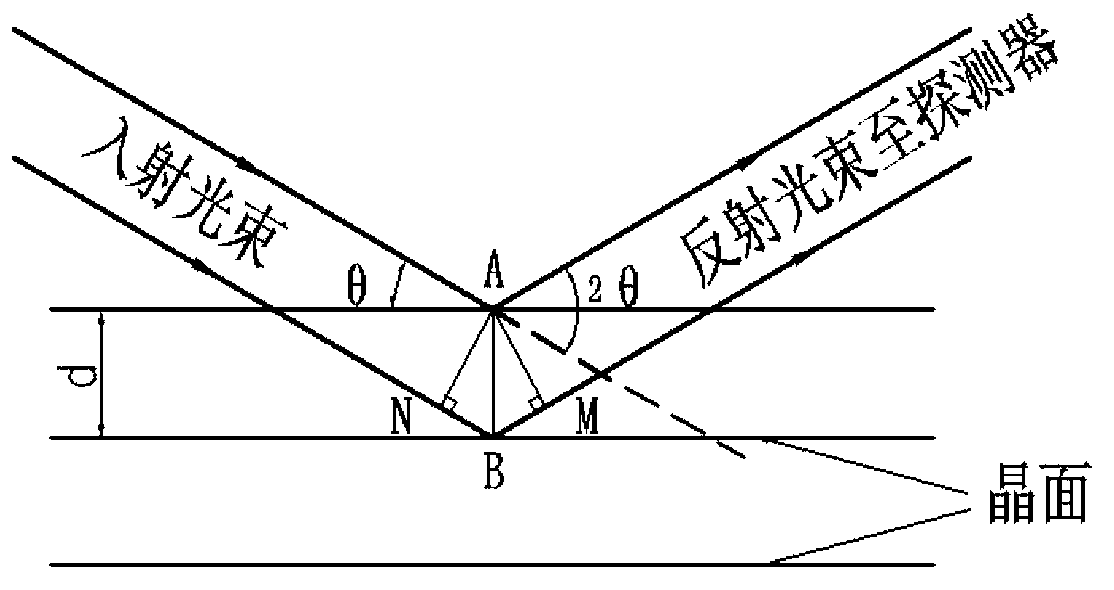

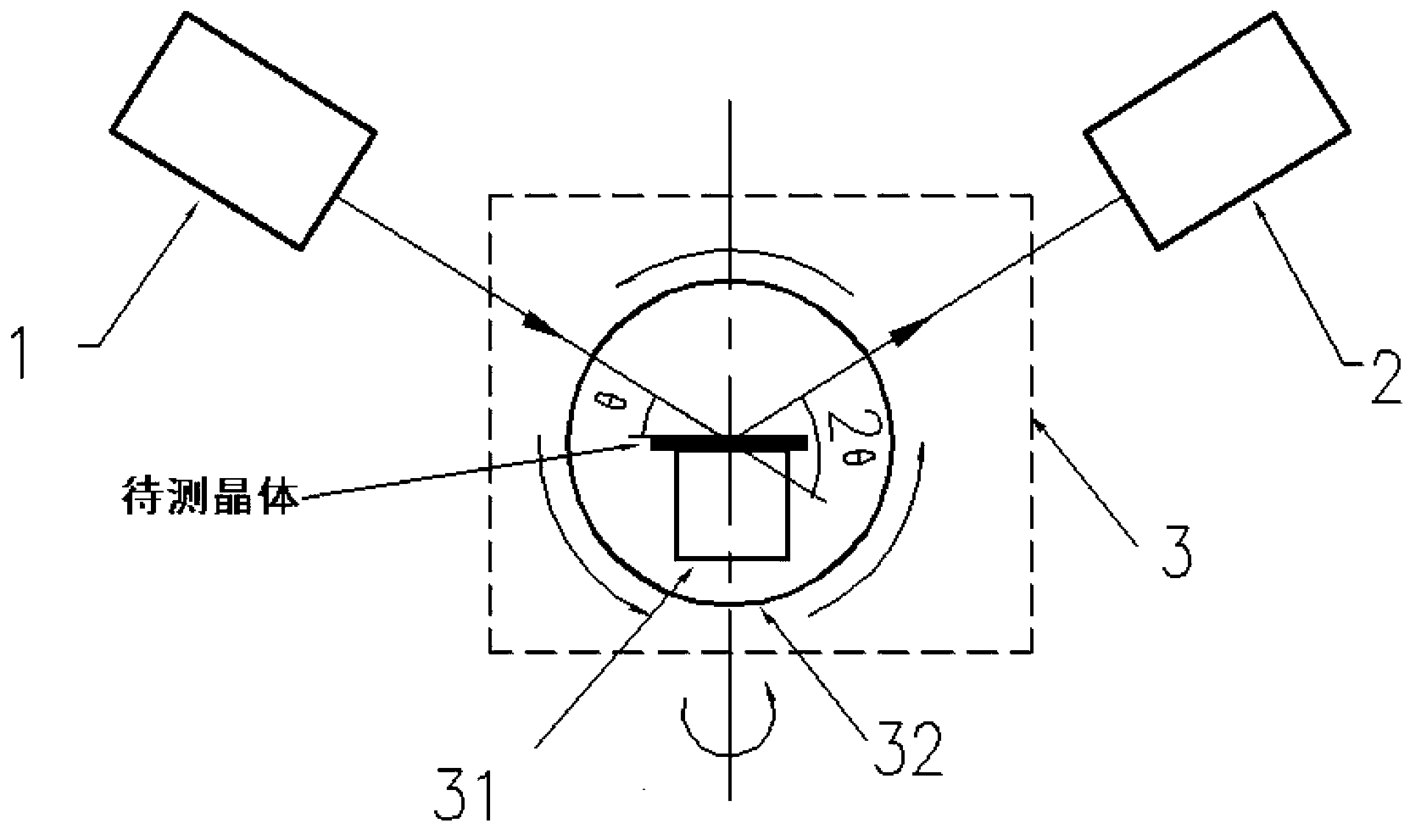

[0044] Step 1: Fix the crystal to be tested on the vertical rotary table 31, so that the normal of the processed surface of the crystal to be tested is in the A plane determined by the incident light and the optical path of the X-ray detector. According to the calibrated crystal plane required by the single crystal, calculate the θ angle and 2θ angle according to the formula (1), and adjust the crystal orientation instrument according to the θ angle and 2θ angle as follows: fix X-ray generator 1, adjust X-ray detector 2 , so that the angle between the incident light and the optical path of the X-ray detector is 2θ. Rotate the horizontal rotating platform 32 so that the incident light and the X-ray detector are separated on both sides of the normal line, and the included angle with the crystal processing surface is θ. At ...

Embodiment 2

[0049] The method for directly measuring the crystal orientation deviation angle of the present invention is characterized in that the steps are as follows:

[0050] Step 1: Fix the crystal to be tested on the vertical rotary table 31, so that the normal of the processed surface of the crystal to be tested is in the A plane determined by the incident light and the optical path of the X-ray detector. According to the calibrated crystal plane required by the single crystal, the θ angle and 2θ angle are calculated according to the formula (1), and the crystal orientation instrument is adjusted as follows according to the θ angle and 2θ angle: Adjust the X-ray generator 1 so that the incident light and the crystal processing The included angles of the X-ray detector 2 are all θ; adjust the angle of the X-ray detector 2 so that the X-ray detector optical path and the crystal processing surface have an angle of θ, and are separated from the X-ray generator on both sides of the normal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com