Electric split four-wheel high-pressure dewatering air-circulation refrigerating system

A refrigeration system, split technology, applied in refrigerators, refrigeration and liquefaction, compressors using turbines, etc., can solve the problem that the cabin air is easily polluted by engine fuel, the manufacturing process of the four-wheel system is complicated, and the three-wheel system is condensed. It can avoid problems such as freezing and blockage of the cockpit, so as to avoid the air pollution of the cabin, reduce the processing difficulty, and reduce the boost ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

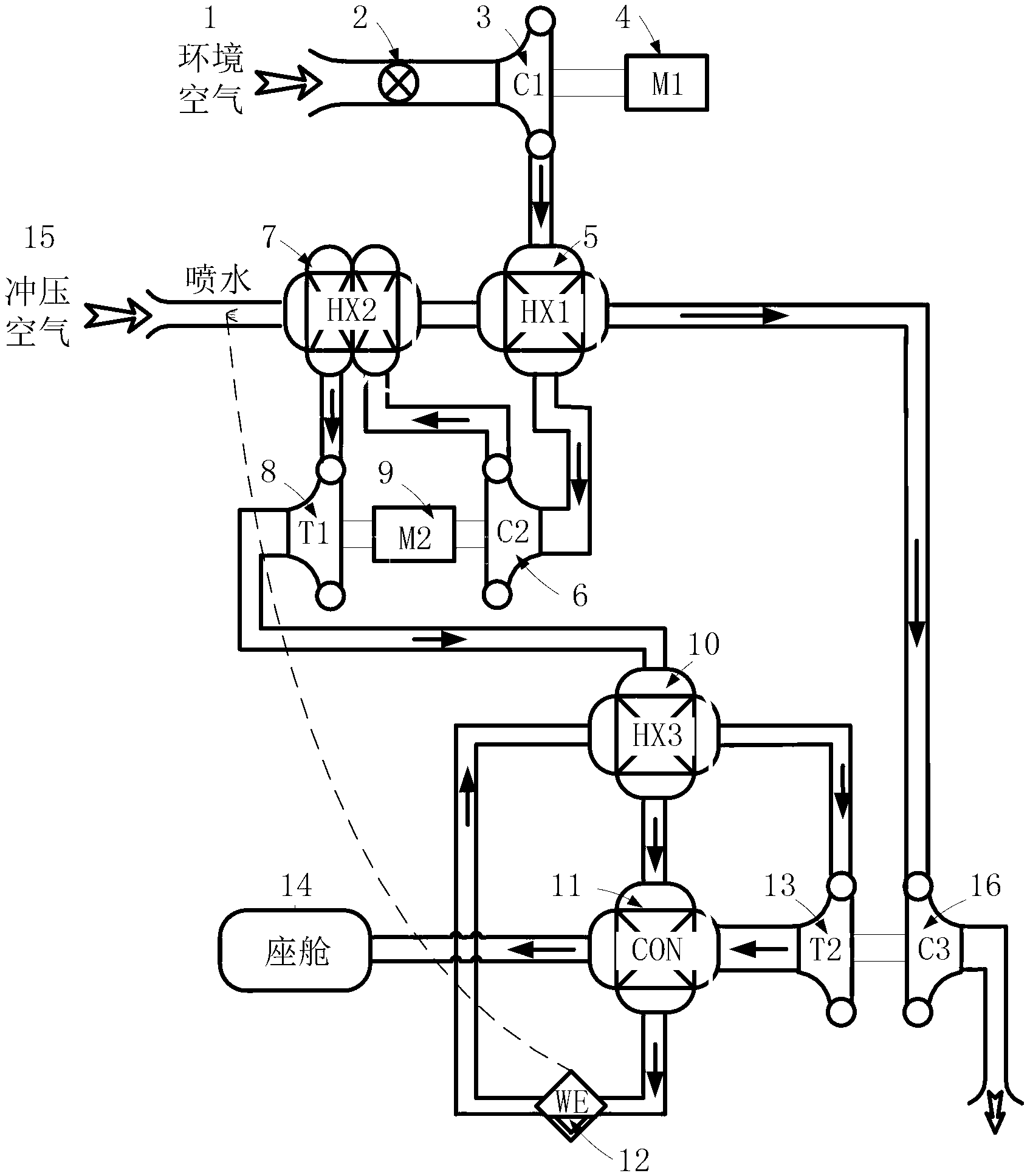

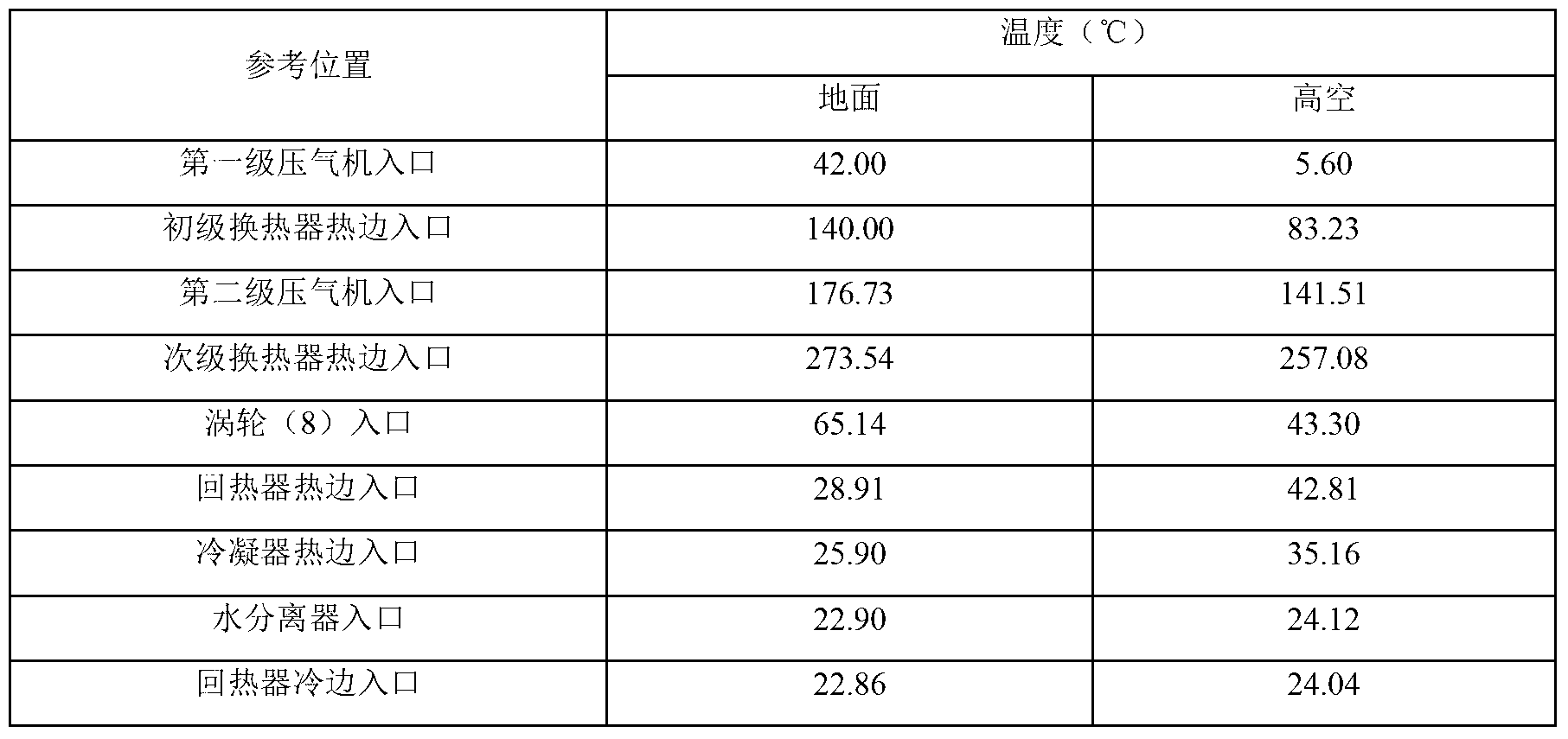

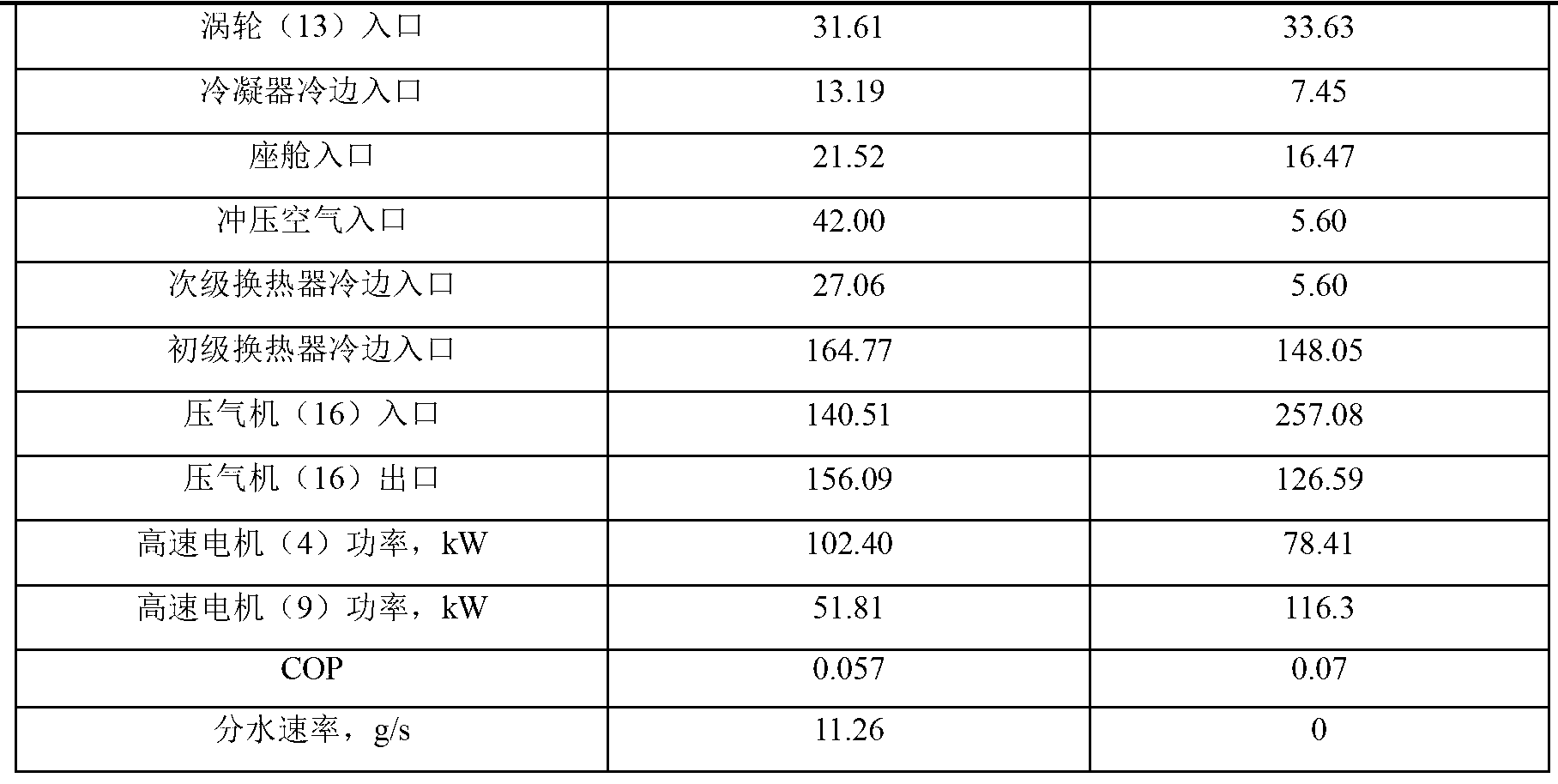

[0015] combine figure 1 Explain the working process of the system: the first-stage compressor (3) is connected with the high-speed motor (4), the ambient air (1) passes through the valve (2), is compressed in the first-stage compressor (3), and flows into the primary heat exchanger (5) On the hot side, the airflow enters the second-stage compressor (6) after cooling down, and the second-stage compressor (6), turbine (8) and high-speed motor (9) are coaxially connected, and the gas is further compressed and then flows into the secondary stage The hot side of the heat exchanger (7) cools down, expands in the turbine (8), reduces the pressure and temperature, and the output work is used to drive the second stage compressor (6). After the gas flows through the hot side of the regenerator (10), the hot side of the condenser (11), the water separator (12), and the cold side of the regenerator (10), it enters the turbine (13) to expand and cool down. The air passes through the cold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com