A control method and control system for furnace negative pressure in a thermal power plant

A furnace negative pressure and control system technology, which is applied in the combustion method, control combustion, lighting and heating equipment, etc., can solve the problems of PID unable to complete stable negative pressure, accelerated furnace pressure drop trend, RB function failure, etc., to prevent furnace The pressure exceeds the lower limit, eliminates negative effects, and prevents the effect of furnace pressure exceeding the limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

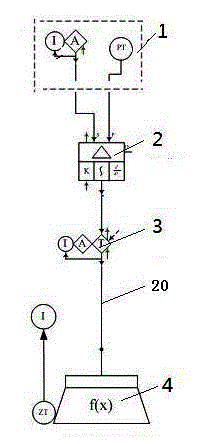

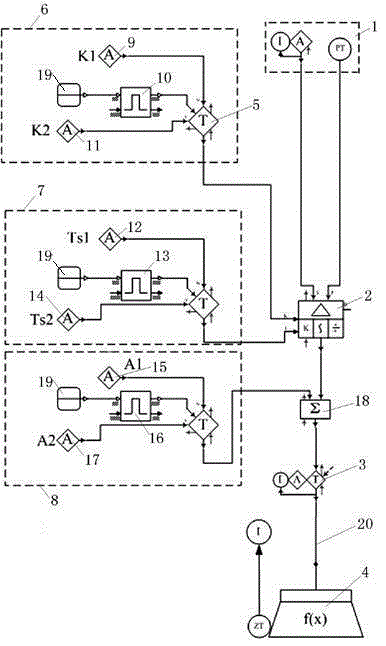

[0021] The control system of the furnace negative pressure of the thermal power plant of the present invention is as figure 1 As shown, it includes a control panel 1 , a PID regulator 2 , an adder 18 , an ID fan vane M / A station 3 and an ID fan vane output 4 . The control panel is connected with the PID regulator circuit, and the PID regulator is connected with the induced fan stator blade control output single-loop circuit 20 through the M / A station of the induced draft fan stator and the adder 18 . The variable proportional coefficient unit 6 is provided with a proportional coefficient constant module 9 , a proportional coefficient switching pulse module 10 , a variable proportional coefficient constant module 11 , a switch input module 19 and a switching module 5 . The switch input module is connected with the proportional coefficient switching pulse module. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com