Pneumatic type gas and slag separation device and method

A gas slag separation, pneumatic technology, applied in the field of pneumatic gas slag separation device, can solve the problems of gas safety hazards and other problems, and achieve the effects of preventing gas from exceeding the limit, reducing water for dust reduction, and smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

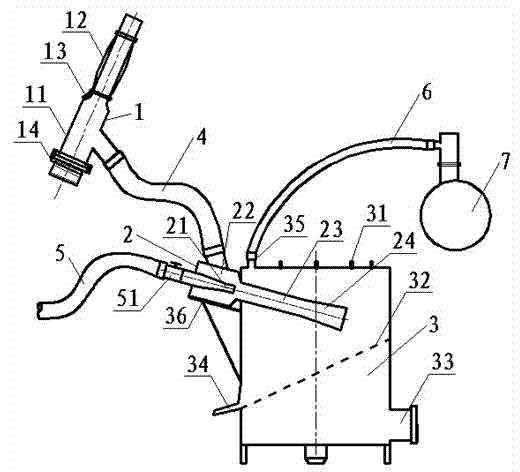

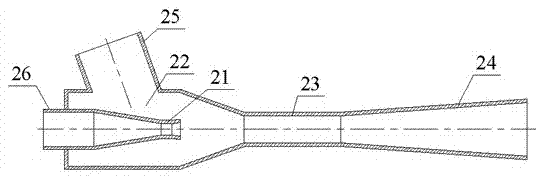

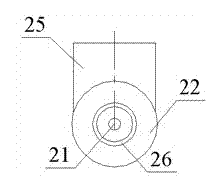

[0016] The structure of the present invention is described in detail below in conjunction with accompanying drawing:

[0017] see figure 1 , the pneumatic gas slag separation device consists of gas dust catcher (1), pneumatic ejector (2), dust separation bucket (3), connecting hose (4), high pressure pipe (5), gas connecting pipe (6) ) and the gas extraction pipeline (7). The connecting hose (4) is connected to the gas dust catcher (1) and the pneumatic ejector (2), and the length can be adjusted freely according to the distance from the drilling hole. The gas connecting pipe (6) connects the dust separation barrel (3) and the gas drainage pipe (7), and the gas separated by the dust separation barrel (3) is input into the gas drainage pipe (7).

[0018] The gas dust catcher (1) is used to collect the dust and gas generated during the drilling process, and the collected gas and slag mixed flow is transported to the pneumatic ejector (2), including the catch sleeve (11), seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com