Fiber rope with surface coated with polymer and preparation method of fiber rope

A surface coating and polymer technology, applied in the direction of textiles, papermaking, textile cables, etc., can solve the problem of lower specific strength, no improvement of high-strength polyethylene fiber surface chemical inertness and non-polarity, fiber surface wettability and interface bonding Poor performance and other problems, to achieve the effect of improving strength and usability, improving chemical inertness, and broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

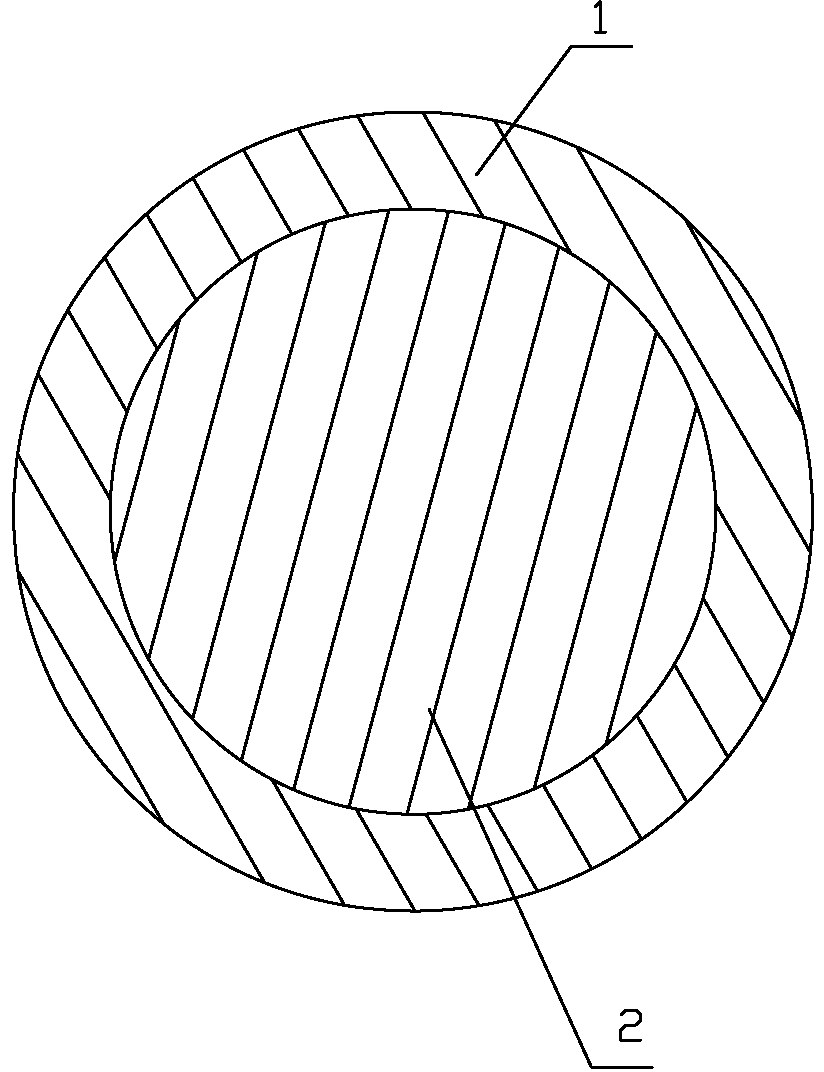

Image

Examples

Embodiment 1

[0023] A preparation method of an ultra-high molecular weight polyethylene fiber rope with surface-coated polymer, characterized in that: it comprises the following steps:

[0024] (1) Weigh the thermoplastic polymer and additives according to the mass ratio, and after mixing evenly, put the mixture into the single-screw extruder through the automatic feeder, and set the temperature of each zone of the single-screw extruder. The temperature is gradually raised to 155°C, mixed and melted to become a molten polymer, which is extruded into the die at the extrusion port; the thermoplastic polymer is 100 parts of polyvinyl chloride particles; the additive is 2 parts of dibutyl ester A mixture of plasticizer, 6 parts activated calcium carbonate enhancer and 2 parts polyacrylate heat stabilizer;

[0025] (2) Pass the fiber rope made of ultra-high molecular weight polyethylene multifilament through the die connected to the extrusion port of the single-screw extruder, and the passing s...

Embodiment 2

[0032] A preparation method of an ultra-high molecular weight polyethylene fiber rope with surface-coated polymer, characterized in that: it comprises the following steps:

[0033] (1) Weigh the thermoplastic polymer and additives according to the mass ratio, and after mixing evenly, put the mixture into the single-screw extruder through the automatic feeder, and set the temperature of each zone of the single-screw extruder. The temperature is set by The temperature was gradually raised from 30°C to 155°C, mixed and melted to become a molten polymer, which was extruded into the die at the extrusion port; the thermoplastic polymer was 100 parts of polyvinyl chloride particles; the additive was 5 parts of dibutyl A mixture of ester plasticizer, 15 parts activated calcium carbonate enhancer and 5 parts polyacrylate heat stabilizer;

[0034] (2) Pass the ultra-high molecular weight polyethylene monofilament through the die connected to the extrusion port of the single-screw extrud...

Embodiment 3

[0041] The preparation method of the PE fiber and the PET fiber composite rope of the surface-coated polymer is characterized in that: it comprises the following steps:

[0042] (1) Weigh the thermoplastic polymer and additives according to the mass ratio, and after mixing evenly, put the mixture into the single-screw extruder through the automatic feeder, and set the temperature of each zone of the single-screw extruder. The temperature is gradually raised to 300°C, mixed and melted to become a molten polymer, which is extruded into the die at the extrusion port; the thermoplastic polymer is 100 parts of vinyl silicone rubber; the additive is 2 parts of dibutyl ester A mixture of plasticizer, 6 parts silica reinforcing agent and 2 parts polyacrylate heat stabilizer;

[0043] (2) Pass the PE fiber and PET fiber composite rope through the die connected to the extrusion port of the single-screw extruder, and the passing speed is 60m / min, and the molten polymer is uniformly coate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Cortical thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com