Method for processing and utilizing low-quality iron ore powder

A processing method and technology for iron ore powder, applied in the field of metallurgy, can solve the problems of short processing time, low processing cost, inability to transport and batch iron ore powder, etc., and achieve the effect of improving profitability and reducing the cost of molten iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

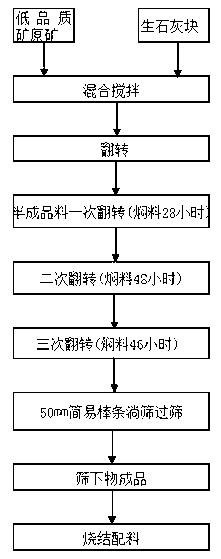

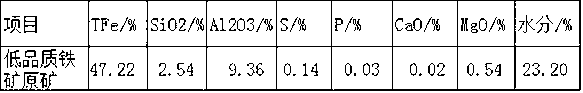

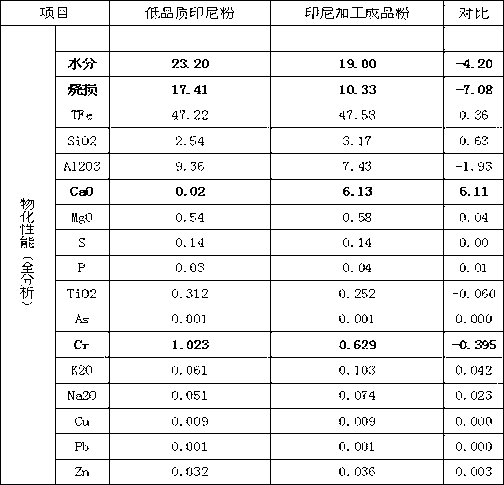

[0033] A processing method of low-quality iron ore powder, taking low-quality Indonesian powder (raw ore) as an example,

[0034] Low-quality Indonesian powder specific implementation work records

[0035] 1. At 8:30 am on March 11, 2013, the Indonesian powder was unloaded and transferred to the processing site of the raw material factory; at 17:00 pm on March 11, 2013, the quicklime block entered the processing site (covered with waterproof canvas); on March 12, 2013 The Indonesian powder processing operation started at 8:45 a.m. on the 1st, and by 12:00 a total of about 720t of mixed materials (covered with waterproof canvas) had been laid, ash mixed, turned and piled.

[0036] 2. At 13:30 pm on March 13, 2013, the processing mixture was turned and piled for the first time; 28 hours later, the processed mixture was turned and piled for the second time, and the visual processing effect was remarkable; 48 hours later, the processing The mixture was stirred for the third time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com