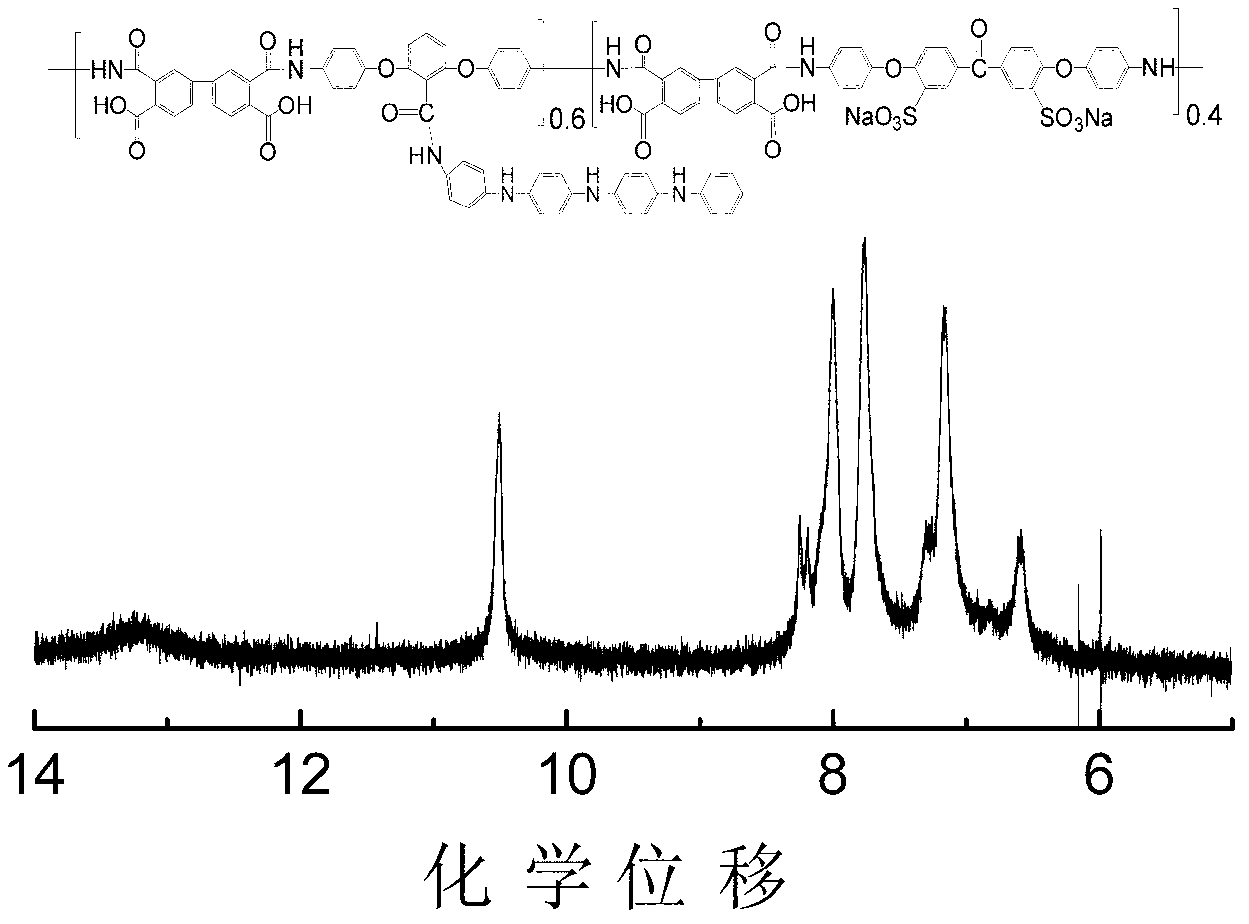

Self-doped electric active polyamic acid, preparation method and application thereof in electrochromic aspect

A technology of polyamic acid and self-doping, which is applied in the direction of color-changing fluorescent materials, chemical instruments and methods, etc., and can solve problems such as non-conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Add 6.54g (0.06mol) of 4-aminophenol and 4.14g (0.03mol) of anhydrous potassium carbonate into a 250mL three-necked flask, add 80mL of DMAc solvent, stir electromagnetically, and add 10mL of toluene after dissolution. Under the protection of nitrogen, the system was heated to 140° C., and the solution was kept under reflux for 2 hours. At this time, the 4-aminophenol was completely converted into the form of phenoxide under the effect of anhydrous potassium carbonate. At this time, after the system was slightly cooled, 15.18 g (0.03 mol) of difluoromonomer (DFAT) was added. Heat the above compound for another two hours and carry water with toluene to ensure that there is no turbidity in the water container (the water has been removed at this time). Then increase reaction temperature, after toluene is steamed, be heated to 160 ℃ of reaction six hours, guarantee that system reaction is complete. Heating was stopped, and after the system was cooled to room temperature, th...

Embodiment 2

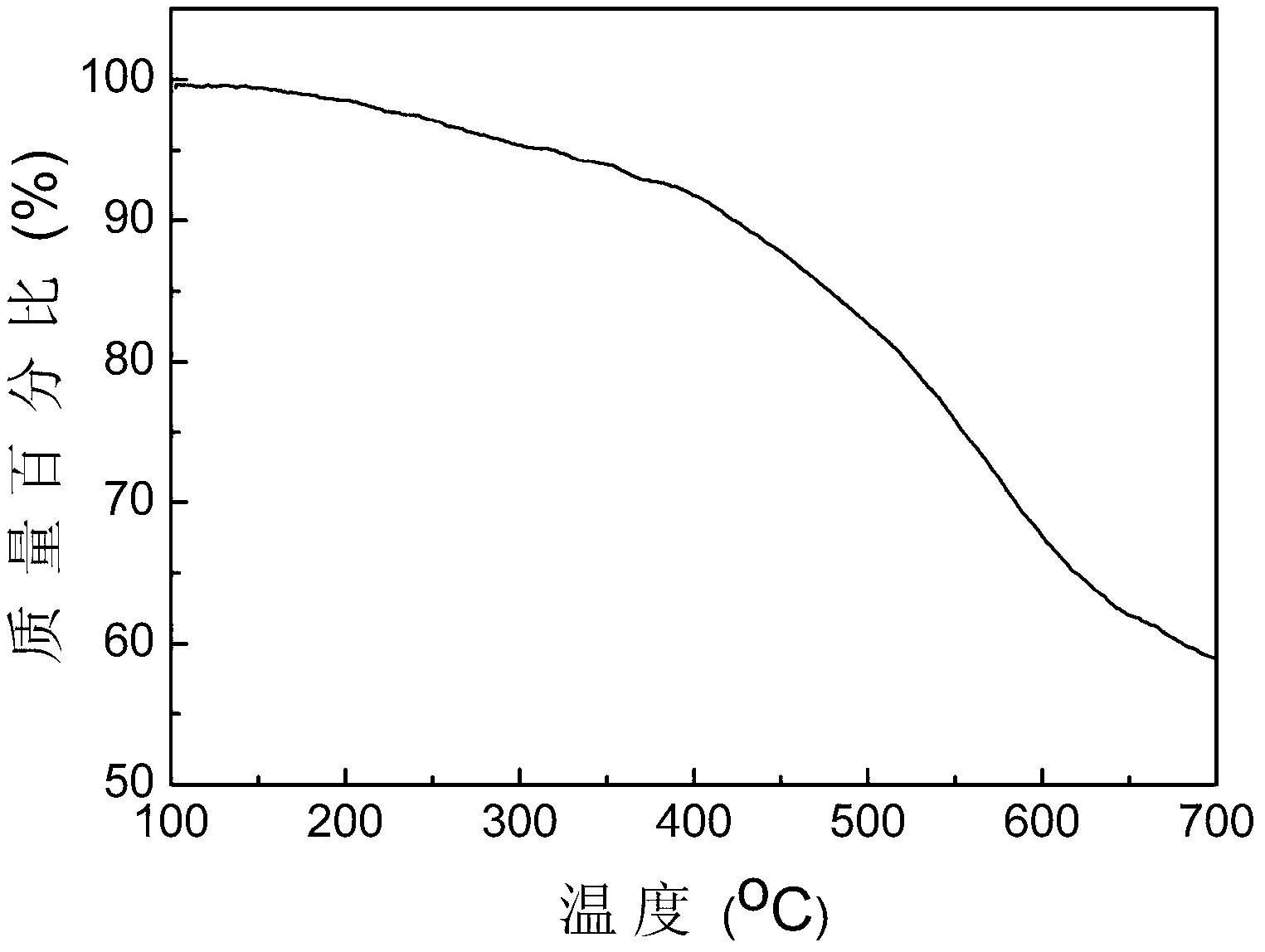

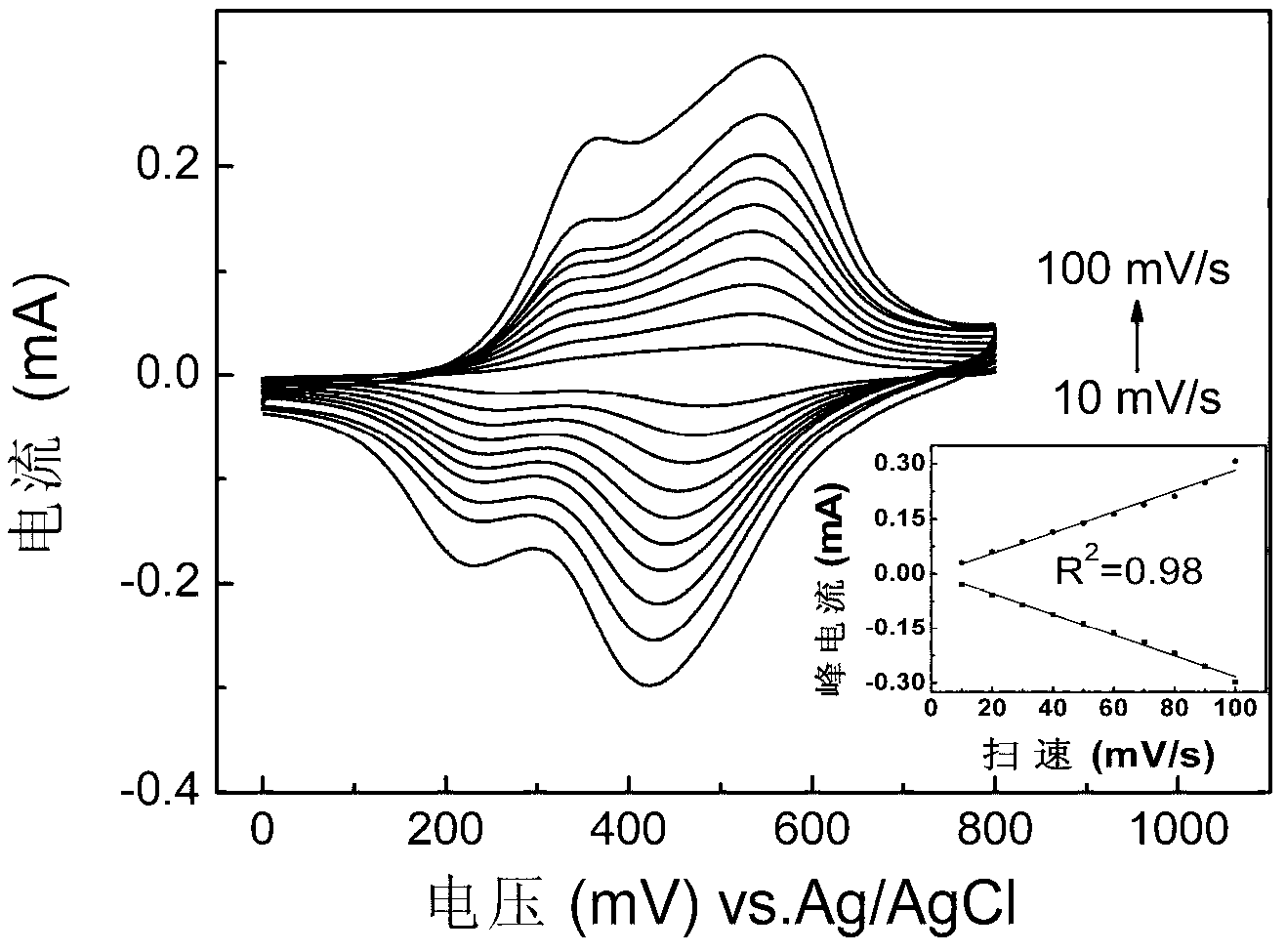

[0042] We synthesized four kinds of copolymers C with the molar ratios of diamine monomer M and diamine monomer N3 being 80:20, 60:40, 40:60, and 20:80, respectively. 1 (PAE-p-OA-X, X represents the percentage of the ratio of diamine monomer N3 to tetraacid dianhydride monomer). Add diamine monomer M and diamine monomer N3 (total 0.01mol) into a three-necked bottle filled with 30mL N,N-dimethylacetamide solution, and add 3,3',4,4 3.10 g (0.01 mol) of '-diphenyl ether tetracarboxylic dianhydride. The percentage of the solid content of the reaction system mass is 25%, the reaction system is stirred under magnetic force, nitrogen protection, and reacts at room temperature for 5 hours, and the polyamic acid solution obtained by the reaction C 1 (PAE-p-OA-X). The viscosity of the polymer (0.84<η<1.29) (where 15<m<25, 25<n<40).

[0043] Polymer C 1 Diluted to a 10% DMAc solution, and spin-coated on ITO glass to form a film to prepare a C / ITO electrode. Then the transmittance of...

Embodiment 3

[0045] The method is as in Example 2, changing 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride to 3,3',4,4'-benzophenone tetracarboxylic dianhydride, using NMP as the organic solvent, Others remain unchanged (the molar ratio of the diamine monomer M to the diamine monomer N3 is 80:20, 60:40, 40:60, 20:80), separated and purified to obtain polymer C 2 . The viscosity of the obtained polymer is in the range of 0.69 to 0.98 (where 15<m<45, 25<n<60). Compared with Example 2, the electrochromic properties of the polymers are basically similar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| coloring efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com