Slow release BB (bulk blending) fertilizer and preparation method thereof

A slow-release, compound fertilizer technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of environmental pollution, low fertilizer utilization rate, etc., and achieve the effect of simple production process, good application effect, and reduction of urea loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

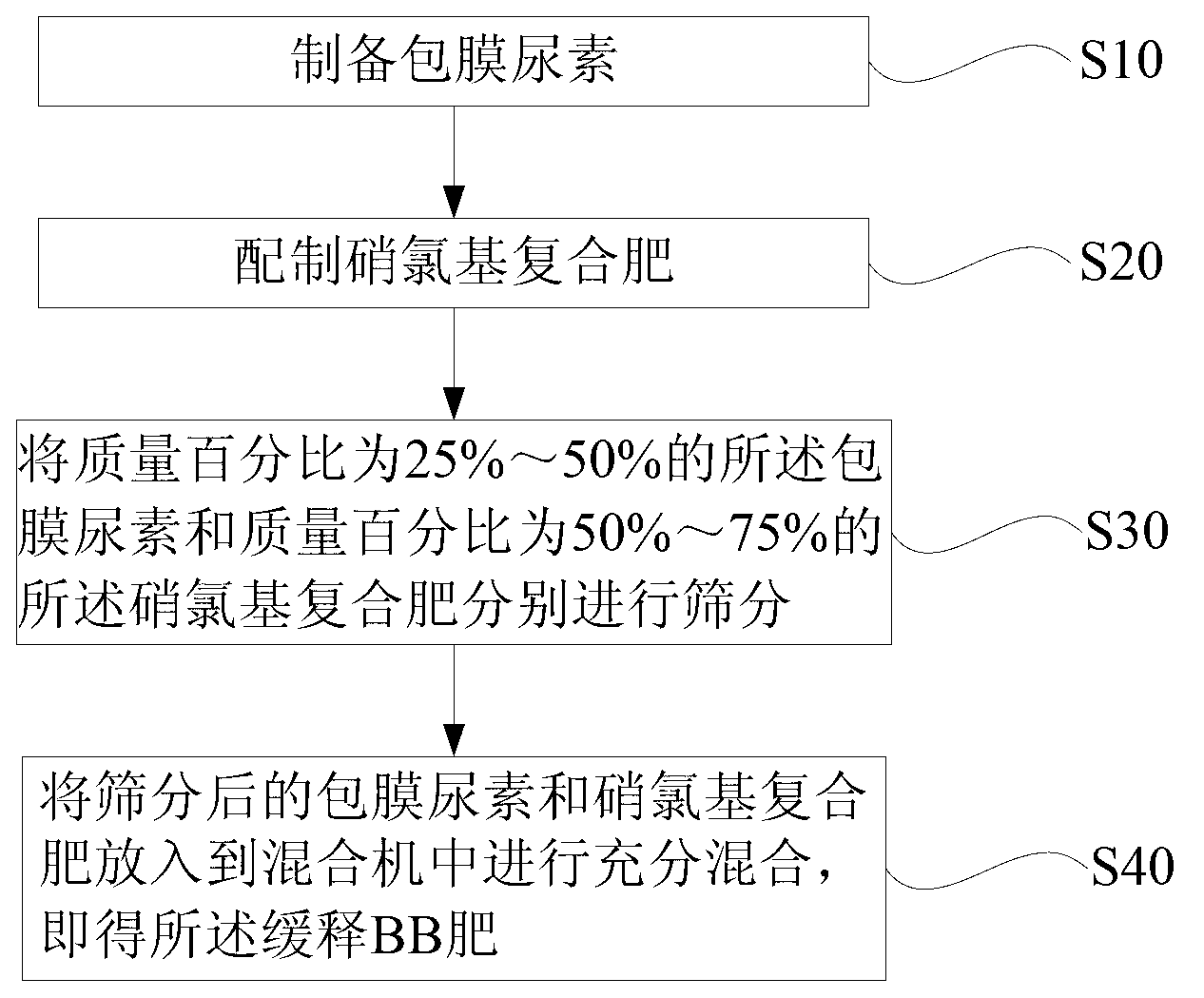

[0049] See figure 1 , The preparation method of the slow-release BB fertilizer provided by the preferred embodiment of the present invention includes the following steps:

[0050] Step S10: preparing coated urea.

[0051] Preferably, the following components are included in the coated urea by mass percentage:

[0052] Urea 95%~97%

[0053] Coating material 1%~4%

[0054] Adhesive 0.01%~3%.

[0055] The preparation of coated urea mainly includes the following steps:

[0056] According to mass percentage, accurately weigh 95%-97% urea, 1%-4% coating material, and 0.01%-3% adhesive for use. The coating material is 800 mesh silica powder, and the adhesive is one of phenolic emulsion or polyacrylic alcohol.

[0057] Put the accurately weighed 95%-97% urea and 0.01%-3% adhesive into the drum mixer for pretreatment. The pretreatment time is 15~45min; then add the weighed 1% to 3% of the coating material, continue to stir and mix for coating treatment, and the coating treatment time is 1 to 2 h...

Embodiment 1

[0070] First prepare coated urea by the following method:

[0071] Pass the silica through an 800 mesh sieve, and weigh 95% urea, 2% 800 mesh silica, and 3% polyacryl alcohol for use; then put 95% urea and 3% polyacryl alcohol together Put into the drum mixer for 15 minutes of pretreatment, then put 2% 800 mesh silica into the mixer and continue to stir and mix for coating treatment, the end of 1 hour; finally put the coated urea into the circle The coated urea is obtained by granulating on a pan granulator, followed by drying and cooling. Among them, the drying time is 20 minutes, and the drying temperature is 70°C.

[0072] Prepare nitrochloro-based compound fertilizer, weigh 9% ammonium nitrate phosphorus, 11% 55% nitric acid, 5% gas ammonia, 12% monoammonium phosphate, 27% ammonium chloride, 23% potassium chloride according to mass percentage And 3% calcium oxide, and mix it to obtain nitrochloro-based compound fertilizer.

[0073] Weigh 25% of coated urea and 75% of nitrochlo...

Embodiment 2

[0075] First prepare coated urea by the following method:

[0076] Pass the silica through an 800 mesh sieve, and weigh 97% urea, 1% 800 mesh silica, and 2% polyacryl alcohol for use; then put 97% urea and 2% polyacryl alcohol together Put it into the drum mixer for 45min pretreatment, then put 1% 800 mesh silica into the mixer and continue to stir and mix for coating treatment, and the end of 2 hours; finally put the coated urea into the circle The coated urea is obtained by granulating on a pan granulator, followed by drying and cooling. Among them, the drying time is 40 minutes, and the drying temperature is 50°C.

[0077] Prepare nitrochloride-based compound fertilizer, and weigh 13% ammonium nitrate phosphorus, 6% nitric acid with a concentration of 55%, 1% ammonia, 16% monoammonium phosphate, 31% ammonium chloride, 27% potassium chloride according to mass percentage And 6% calcium oxide, and mix it to obtain nitrochloride-based compound fertilizer.

[0078] Weigh 50% of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com