Method and complete set of equipment for reducing oxygen content in gasification process of CO2 gas of brewery

A technology of oxygen content and gas, applied in the application field of liquid carbon dioxide, can solve the problems of difficulty in reducing the taste of beer and the preservation period, and achieve the effects of being beneficial to environmental protection, low energy consumption, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

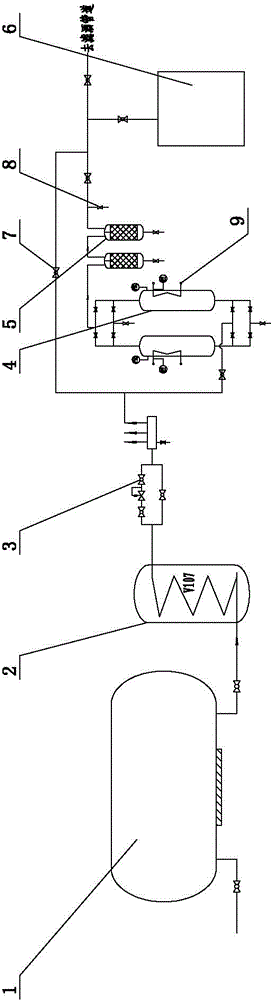

[0026] A way to reduce brewery CO 2 The method of oxygen content in the process of gasification, firstly, the liquid carbon dioxide in the liquid storage tank 1 with a pressure of 1.5-1.8 MPa is first vaporized by the vaporization device 2 to become gaseous carbon dioxide, and then decompressed to 0.6-0.6 by the decompression device 3. 0.9 MPa enters the oxygen removal device 4, and passes through the adsorbent filled in the oxygen removal device (the adsorbent can be an alloy such as manganese), the flow rate of carbon dioxide in the adsorbent is 10-30 m / s, and the carbon dioxide contained in the carbon dioxide gas is absorbed by the adsorbent Oxygen adsorption realizes deoxygenation, and the deoxygenated carbon dioxide gas passes through the filter device 5 to remove dust and odor, and finally the deoxygenated carbon dioxide gas can enter the high-concentration diluter and / or wine filter pipeline for use.

Embodiment 2

[0028] A way to reduce brewery CO 2 A complete set of oxygen content in the gasification process, which includes CO 2 Carburetor 2, decompression device 3 (CO 2 pressure reducing valve), oxygen removal device 4 and filter device 5, such as figure 1 As shown, CO 2 The input of vaporizer 2 is connected to the CO 2 Connected to the output of liquid storage tank 1, CO 2 The output end of the vaporizer 2 is connected to the input end of the decompression device 3, the output end of the decompression device 3 is connected to the input end of the oxygen removal device 4, the output end of the oxygen removal device 4 is connected to the input end of the filter device 5, and the filter device The output end of 5 is connected with the input end of high-concentration diluter 6, and adsorbent is filled in deaeration device 4, such as figure 1 As shown, the adsorbent in the oxygen removal device 4 can be an alloy such as manganese, and the flow rate of carbon dioxide in the adsorbent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com