Preparation method of ginkgo leaf essence

A technology of Ginkgo biloba extract and Ginkgo leaf, which is applied in the field of preparation of Ginkgo biloba extract refined product Ginkgo biloba extract, can solve the problems of many inorganic chemical media, high cost, complex process, etc., to improve the stability of properties and increase the content And the effect of easy control of proportion and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

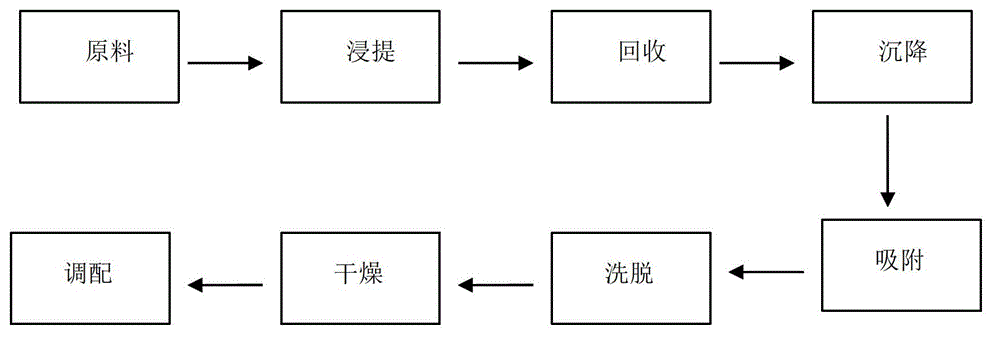

Method used

Image

Examples

Embodiment 1

[0026] Get 100kg of Ginkgo biloba leaves, use 12, 10, and 10 times the amount of 40% ethanol (referring to the ratio of raw material weight to solution volume, the same as in the following example). Immersion and stirring at 80°C for three times, 2 hours each time, release the extract, combine and concentrate to a small volume, add 5 times the amount of purified water to dilute, and add 5 times the amount of purified water after crude separation of the medicinal solution at 0°C or - Settling at 1°C. The supernatant was passed through styrene macroporous adsorption resin (AB-8), washed with 2 times the resin volume of water, eluted with 20% ethanol, and then eluted with 70% ethanol to collect the eluate. The resin can be reused after regeneration. The eluate was concentrated under reduced pressure, then dried under reduced pressure, and the temperature was controlled to be less than or equal to 75°C to obtain 2.4 kg of Ginkgo biloba extract containing 26.5% of ginkgo flavonol ...

Embodiment 2

[0028] Take 200kg of Ginkgo biloba leaves and pulverize it into coarse powder, extract 10, 6, and 5 times the amount of 75% ethanol at 70 ° C for three times, each time for 3 hours, release the extract, combine and concentrate to a small volume, and add 8 times the amount of purified water. Diluted, after crude separation of the medicinal solution, the purified water was added to make the volume to 1600L, and the solution was allowed to settle at a temperature of 20°C. The supernatant was passed through a styrene macroporous adsorption resin column (DM-130), washed with 2 times the resin volume of purified water, eluted with 30% ethanol, and then eluted with 95% ethanol to collect the eluate. The resin can be reused after regeneration. The eluate is concentrated under reduced pressure at a temperature of less than 75°C, and then spray-dried to obtain 4.6kg of Ginkgo biloba extract containing flavonol glycosides ≥ 28%, ginkgo terpene lactones ≥ 9%, and ginkgo lactones up to 4.5...

Embodiment 3

[0030] Take 200kg of Ginkgo biloba leaves and pulverize them into coarse powder, extract 9, 7, and 5 times the amount of 85% ethanol at 70 °C for three times, each time for 3 hours, release the extract, combine and concentrate to a relative density of 1.20 at 70 °C, add 8 times After the crude separation of the medicinal liquid, the purified water was added to dilute to 1600L, and the liquid was allowed to settle at a temperature of 20°C. The supernatant was passed through a styrene macroporous adsorption resin column (DM-130), washed with 2 times the resin volume of purified water, eluted with 25% ethanol, and then eluted with 90% ethanol, and the eluate was collected. The resin can be reused after regeneration. Eluent with CO 2 Supercritical fluid drying, the conditions are: drying temperature 40 ℃, pressure 15MPa, CO 2 The flow rate is 20kg / h, and 5.2kg of Ginkgo biloba extract containing flavonol glycosides ≥28%, ginkgo terpene lactones ≥10%, of which ginkgo lactones are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com