Seal structure for fuel cell

A technology of fuel cell and sealing structure, applied in the field of sealing structure, to achieve the effect of easy component shape, manufacturing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0068] Next, embodiments of the present invention will be described with reference to the drawings.

no. 1 example

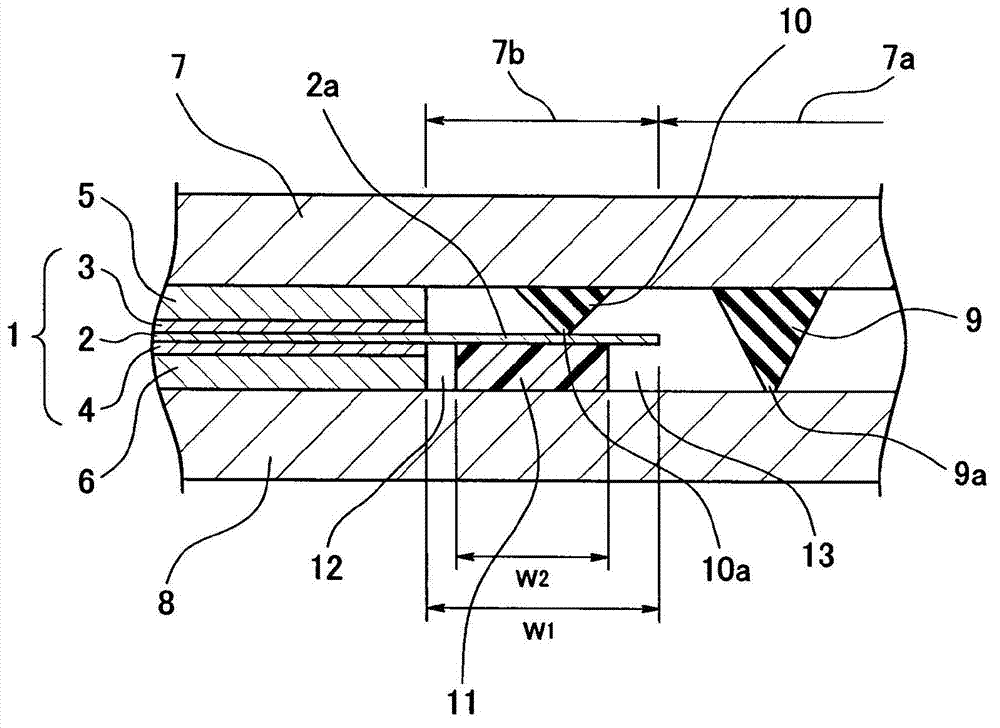

[0070] figure 1 A main part cross-section of the fuel cell sealing structure according to the first embodiment of the present invention is shown, and the sealing structure is configured as follows.

[0071] That is, first, as a basic configuration, a membrane electrode assembly (MEA) 1 in which a pair of (anode side and cathode side) electrode layers 3 and 4 are provided on both sides of the electrolyte membrane 2 in the thickness direction is provided. 1 is sandwiched by a pair of separation devices 7, 8 via a pair of gas diffusion layers (GDL) 5, 6. As the relationship between the dimensions of these fuel cell components, the planar dimensions of the pair of electrode layers 3, 4 and the pair of gas diffusion layers 5, 6 are set to be the same as each other, and the planar dimensions of the electrolyte membrane 2 are set to be larger than those of the electrode layers. 3 and 4 and the gas diffusion layers 5 and 6 have large planar dimensions, and the planar dimensions of t...

no. 4 example

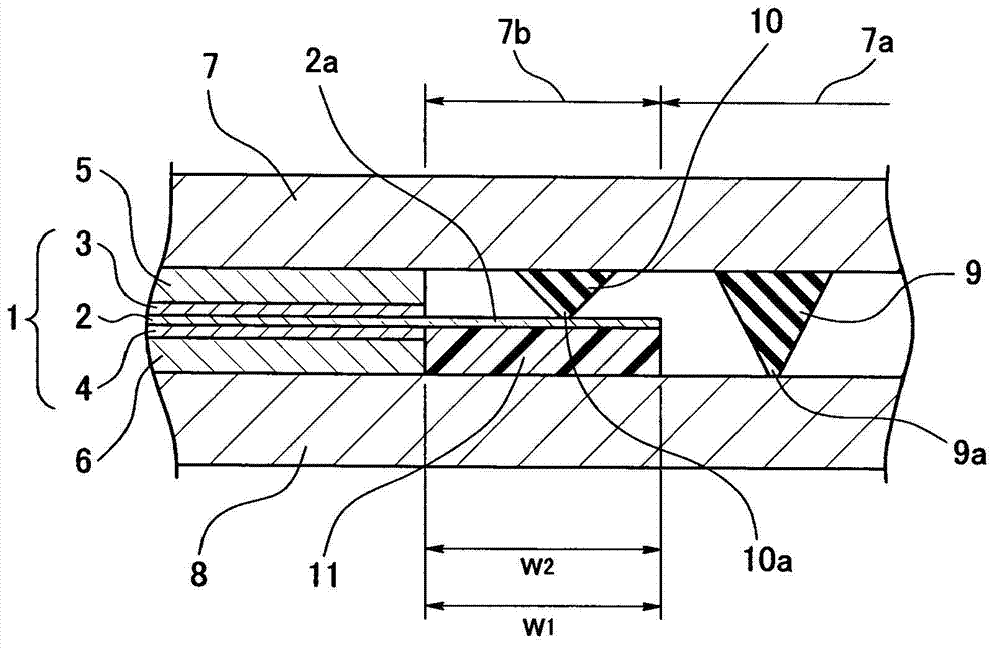

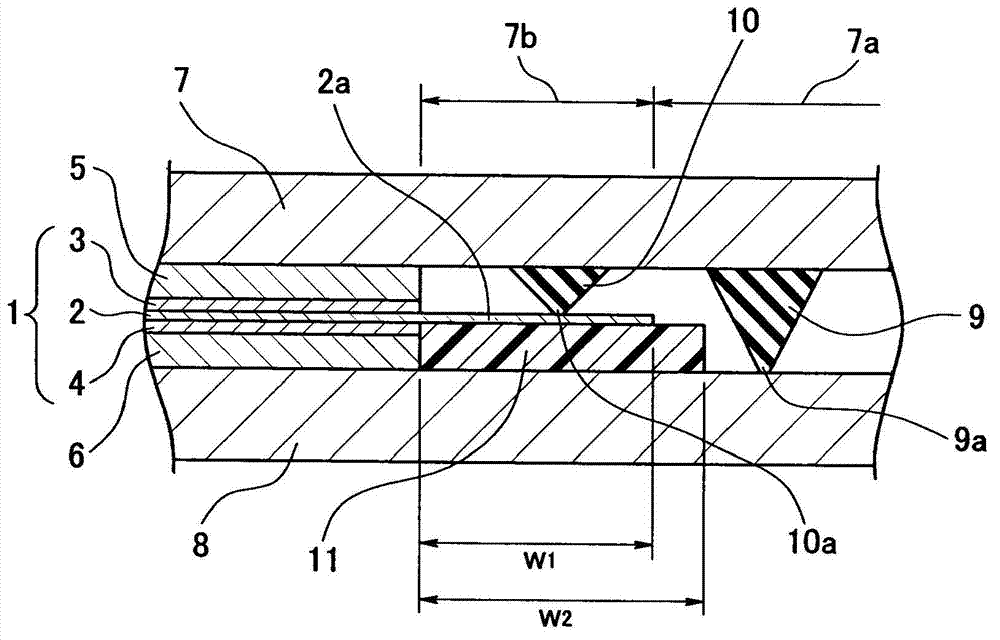

[0083] Figure 4 A cross section of a main part of a fuel cell sealing structure according to a fourth embodiment of the present invention is shown, and the sealing structure is configured as follows.

[0084] That is, first, as a basic configuration, a membrane electrode assembly (MEA) 1 in which a pair of (anode side and cathode side) electrode layers 3 and 4 are provided on both sides of the electrolyte membrane 2 in the thickness direction is provided. 1 is sandwiched by a pair of separation devices 7, 8 via a pair of gas diffusion layers (GDL) 5, 6. As the relationship between the dimensions of these fuel cell components, the planar dimensions of the pair of electrode layers 3, 4 and the pair of gas diffusion layers 5, 6 are set to be the same as each other, and the planar dimensions of the electrolyte membrane 2 are set to be larger than those of the electrode layers. 3 and 4 and the gas diffusion layers 5 and 6 have large planar dimensions, and the planar dimensions of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com