Epoxy resin composition for resin transfer molding of fiber-einforced composite material, fiber-reinforced composite material, and method for producing same

A technology of epoxy resin and composite material, applied in the field of epoxy resin composition and fiber reinforced composite material, can solve the problems of stagnation and productivity obstacles, and achieve the effects of excellent operability, high heat resistance and excellent impregnation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12)

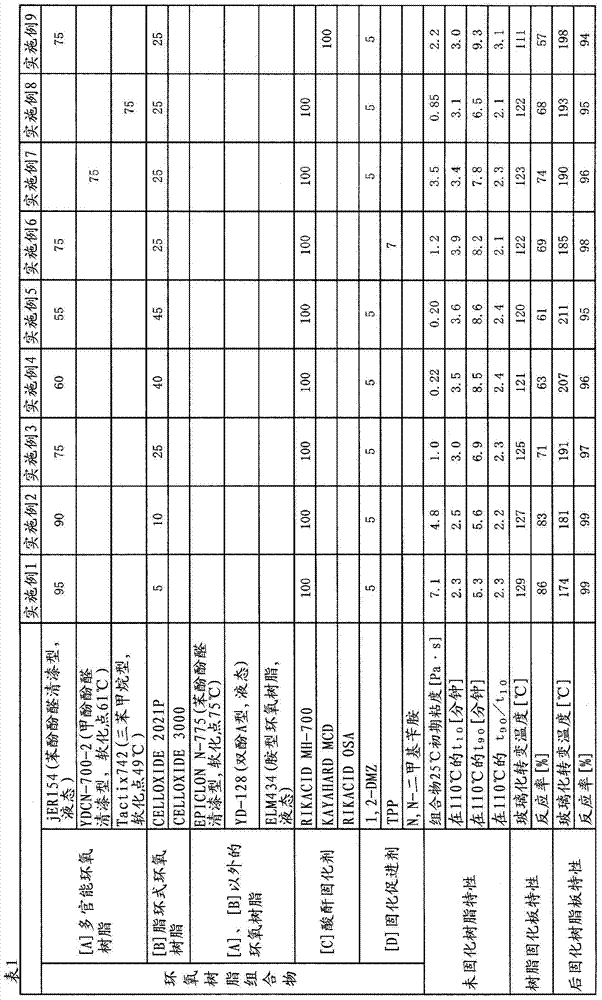

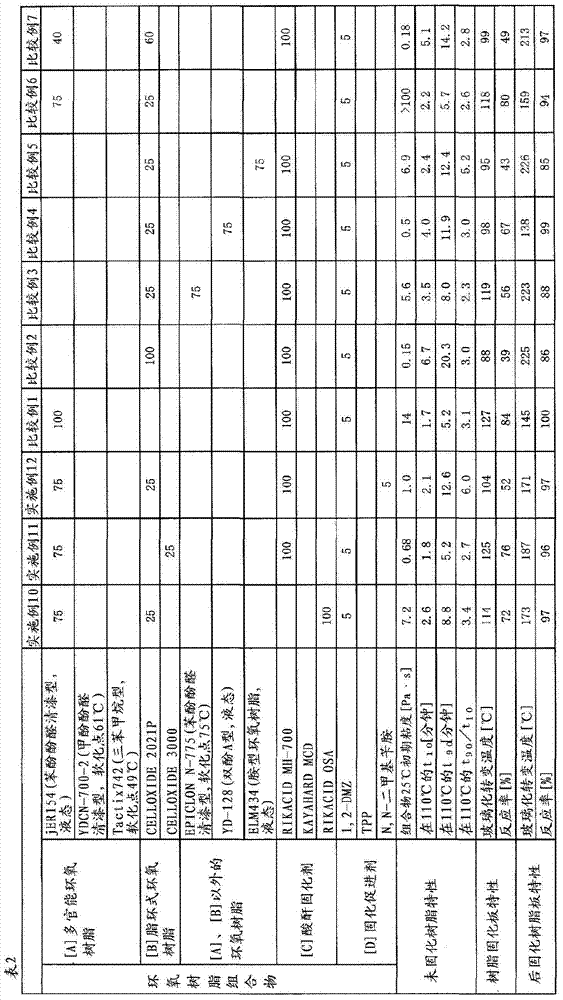

[0159] As described above, epoxy resin compositions were prepared with the compositions shown in Tables 1 and 2, and viscosity measurement and dielectric constant measurement were performed. Also, using the prepared epoxy resin composition, as described above, a resin-cured board and a post-cured resin board were produced, and the glass transition temperature Tg and the reaction rate were measured.

[0160] As shown in Tables 1 and 2, since the curing agent and the catalyst in the epoxy resin composition of the present invention are low-viscosity liquids, the mixing workability is excellent. In addition, due to the low initial viscosity of the resin composition, at the molding temperature (110°C) by t 10 The indicated flow time is long, so it has excellent impregnation and filling properties for reinforcing fibers. And it can be seen that by t 90 The demoulding time indicated is short, so t 90 / t 10 The value of is less than 3, which can effectively shorten the molding tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com