Built-in power supply type LED (Light-Emitting Diode) fluorescent tube safety power-up switch

A technology for LED fluorescent lamps and electric switches, applied in electric switches, light sources, circuits, etc., can solve problems such as increasing installation time and difficulty, line short circuits, and hidden safety hazards, so as to reduce fire accidents, improve safety, and improve safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with the accompanying drawings.

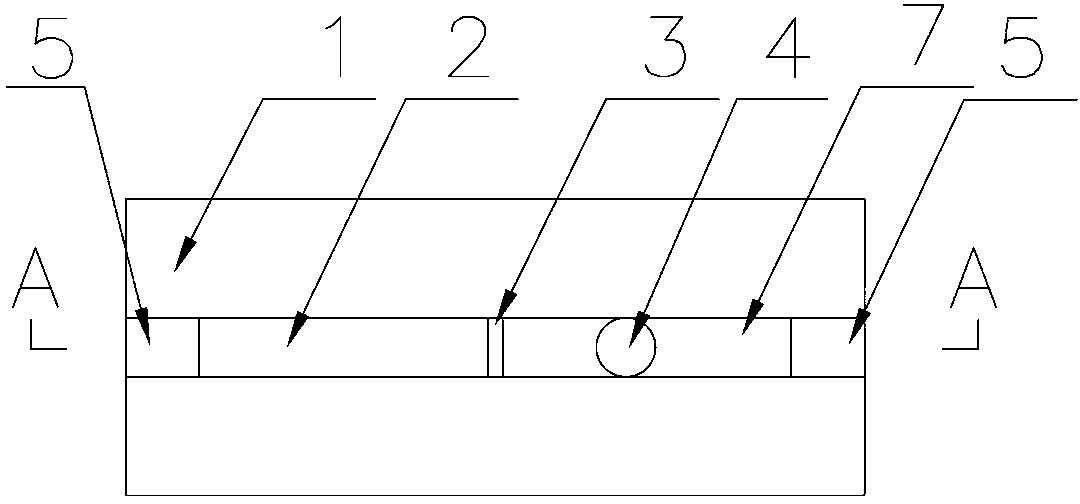

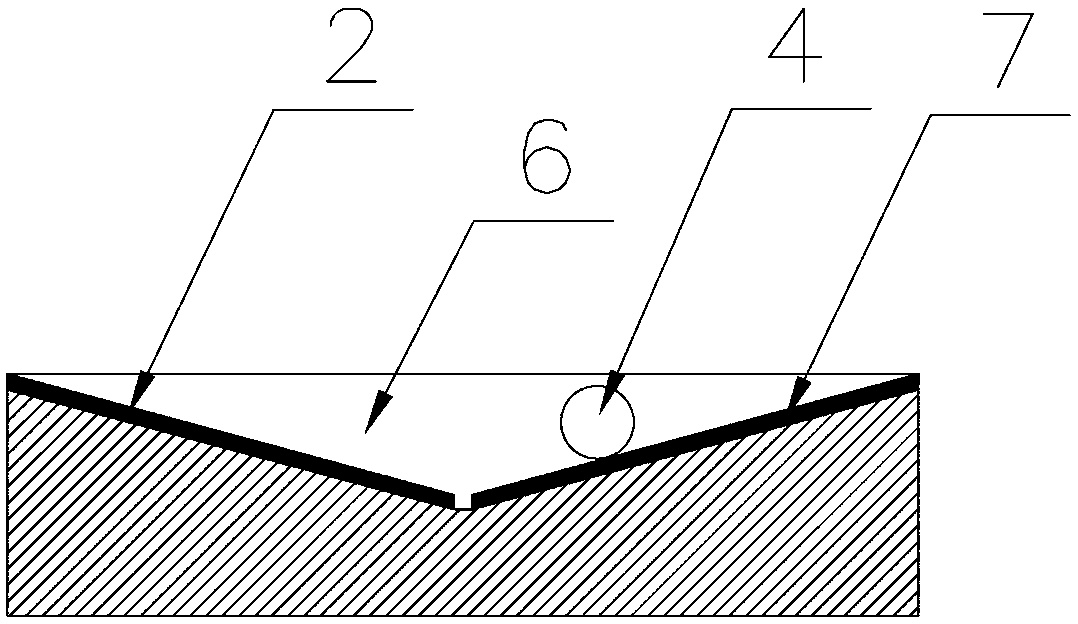

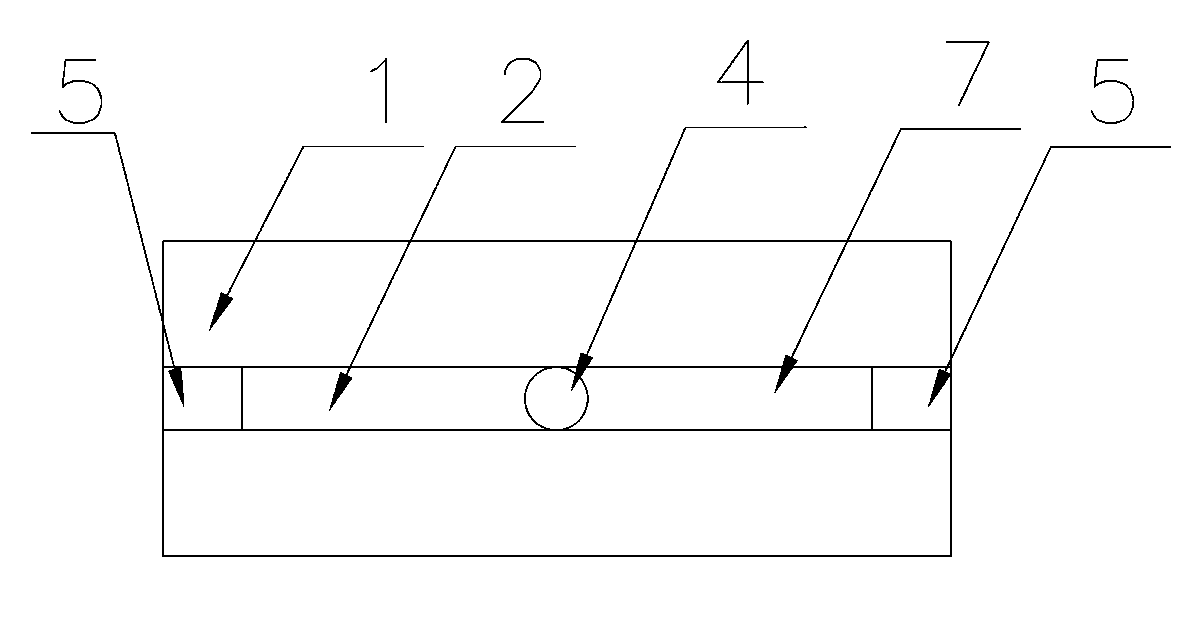

[0017] Such as figure 1 , figure 2 As shown, a built-in power supply type LED fluorescent tube safety power-on switch, including a housing 1, the housing 1 is provided with a first conductive electrode 2 and a second conductive electrode 7, the first conductive electrode 2 and the second conductive electrode An insulating gap 3 is provided between the two conductive electrodes 7, and the first conductive electrode 2, the second conductive electrode 7, and the insulating gap 3 form a cavity 6, and a cavity 6 is installed on the cavity 6. The metal gravity ball 4 that rolls and then affects the on-off of the switch is provided with a lead pad 5 on both the first conductive electrode 2 and the second conductive electrode 7 .

[0018] During specific use, the safe power-on switch of the present invention is used for LED fluorescent lamp tubes. Before the LED fluorescent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com