Graphene plastic casing light-emitting diode (LED) bulb lamp and production method thereof

A technology for an LED bulb lamp and a production method, which is applied to lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve the problems of heavy weight and large size of lamps, and achieve extended life, long life of the whole lamp, and convenience. The effect of promoting the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

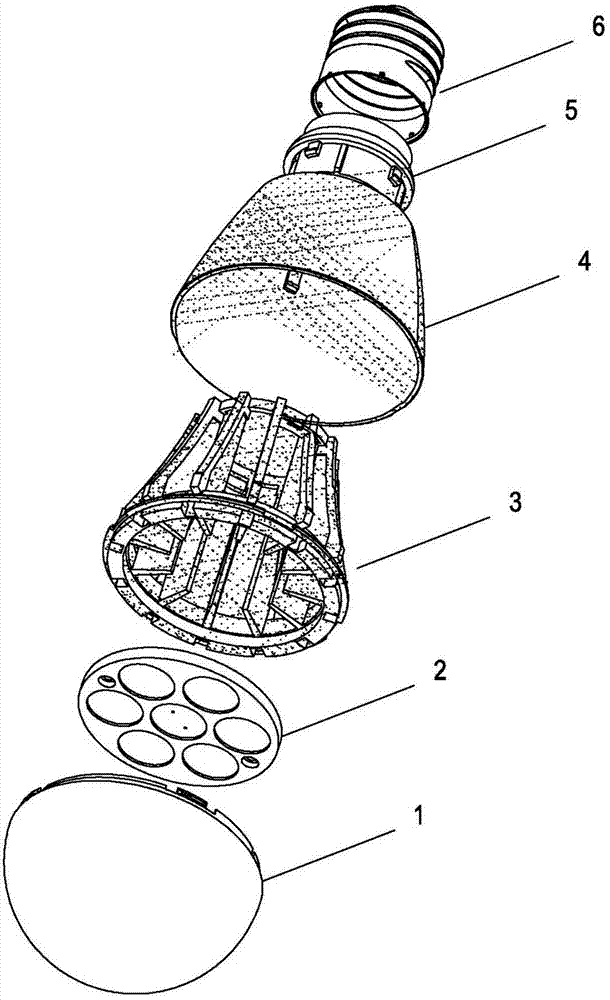

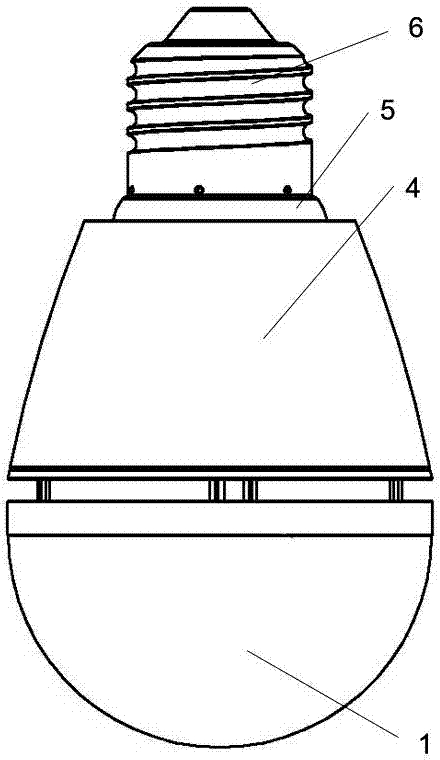

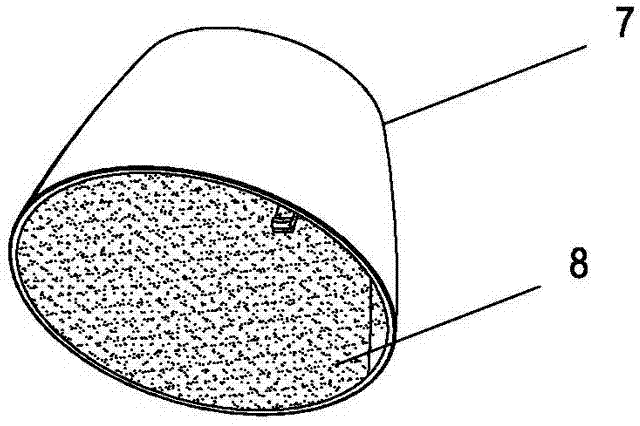

[0030] Such as Figure 1-3 As shown: the present invention consists of a lamp cap 6, a driving power supply 5 adjacent to the lamp cap, a light source base 3 connected to the driving power source, an LED light source 2 installed on the light source base, a casing 4, and a light-transmitting bulb connected to the top of the casing 1 composition. The light-transmitting bulb 1 is screwed on the top of the shell 4 , and the drive power 5 built in the lamp holder 6 is screwed on the bottom of the shell 4 . The LED light source 2 is tightly fixed on the light source base 3 by clamping, screw fixing, bonding, etc., and is closely connected with the light source base 3 . The shell is a fireproof plastic shell 7 whose inner surface is covered with a graphene material layer 8 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com