Improved noise reduction control for wind turbines

A wind turbine and noise technology, which is applied in the field of improved noise reduction control for wind turbines, can solve the problems of wind turbine reduction cost-effectiveness, and achieve the effect of accurate prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

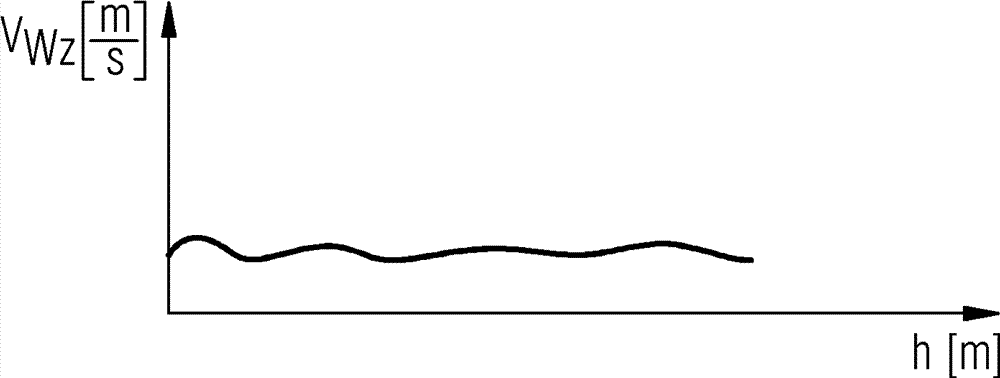

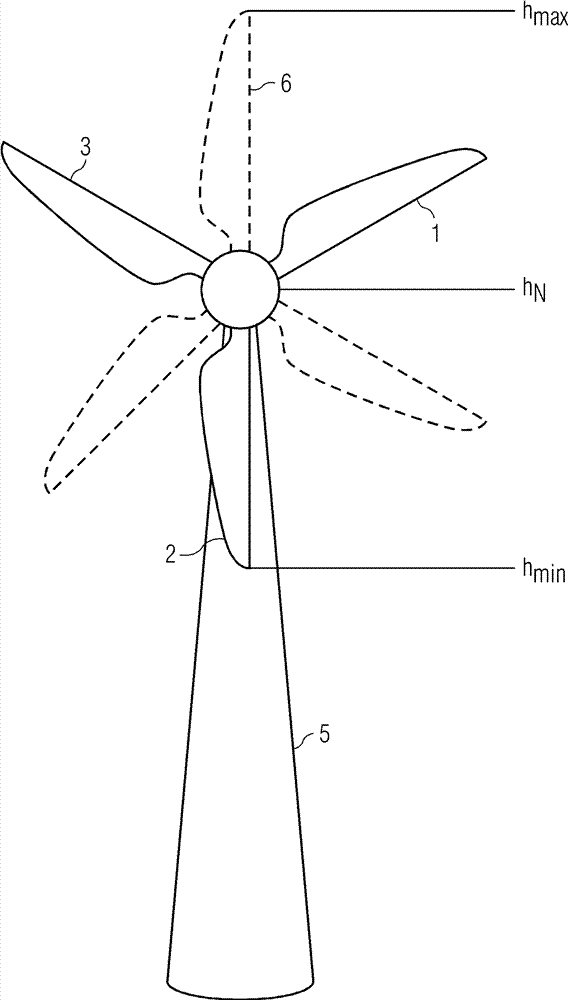

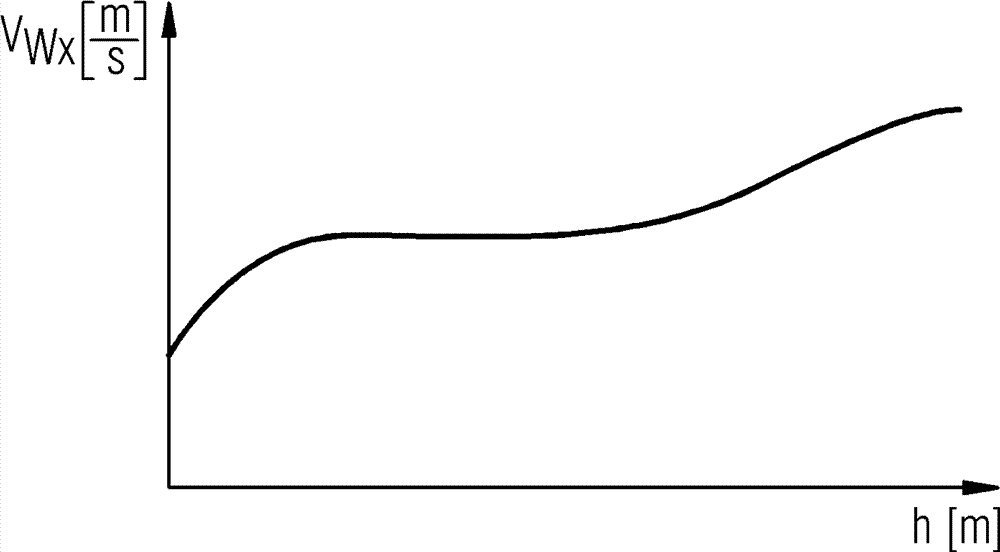

[0028] figure 1 shows the wind velocity v as a function of height h w the first graph of . This wind speed profile is merely exemplary in nature and relates only to real examples where the wind speed is typically lower at lower altitudes above ground than at higher altitudes.

[0029] In this graph, h N represents the height of the nacelle of the wind turbine, and h min and h max Indicates the minimum and maximum heights of the rotor blade tips. As can be seen from this graph, the force applied to the rotor blades will vary greatly with rotor azimuth because of the difference in wind speed at different heights. Different wind speeds also mean that the noise emission will vary depending on the rotor azimuth. If the rotor blade pitches with a low noise emission at one rotor azimuth, the selected pitch may not be suitable for a different rotor azimuth and cause an unnecessary amount of noise for a second rotor azimuth. This is because the wind speed increases with the min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com