Method for generating combustion resonance steam from emulsified crude oil for heating oil wells

A technology of emulsifying crude oil and crude oil, which is applied in earthwork drilling, wellbore/well components, production fluids, etc., can solve the problems of high cost, slow oil layer heating temperature, long oil production cycle, etc., and achieve high thermal energy conversion efficiency and equipment Create easy, easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

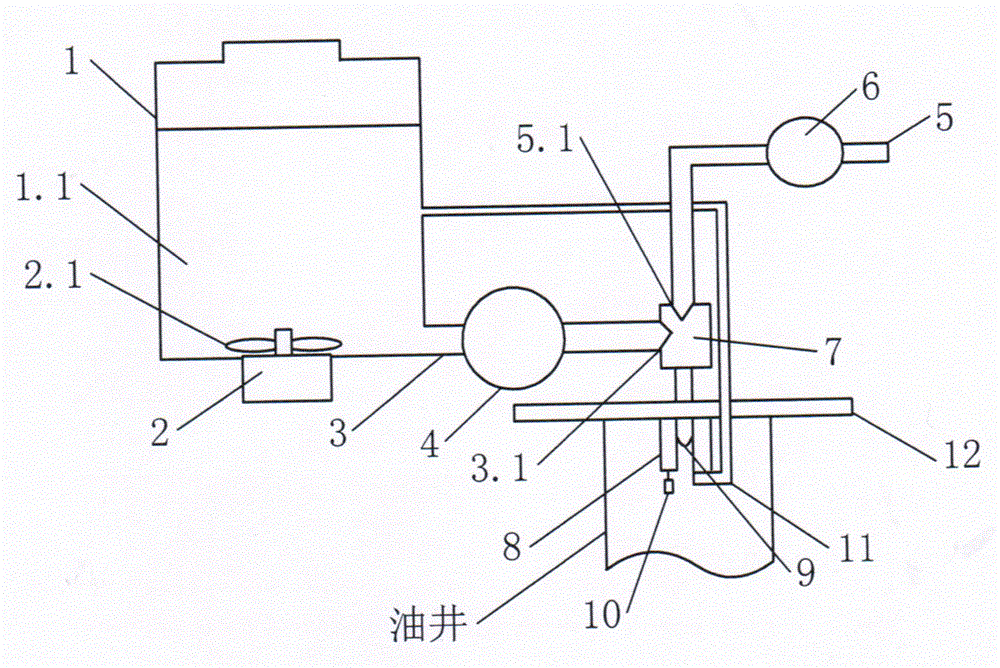

[0014] According to the picture:

[0015] 1. Crude oil emulsification: first inject crude oil into the crude oil emulsification tank 1, then add water with emulsifier in proportion to the crude oil emulsification tank, start the stirring motor 2, drive the agitator 2.1 to rotate and stir, and make the crude oil and water Emulsified to become emulsified crude oil, the emulsified crude oil is sprayed into the oil-air mixer 7 through the delivery pipe 3 and the high-pressure oil pump 4 through the emulsified oil nozzle 3.1, and mixed with the air input from the air inlet 5, the air compressor 6 and the air nozzle 5.1;

[0016] 2. Resonant steam generation: The emulsified gasified crude oil mixed with the oil-gas mixer is ejected from the steam injection port 9 under pressure, and at the same time, the igniter 10 is started to ignite the emulsified gasified crude oil to burn and generate steam; the steam passes through the resonator 8 Generate a resonance wave consistent with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com