Preparation method of high-temperature-resistant SiBN(C) carbon fiber coating

A technology of carbon fiber and high temperature resistance, which is applied in the field of preparation of modified carbon fiber, which can solve the problems of limited carbon fiber application, poor high temperature oxidation resistance of carbon fiber, and decline in mechanical properties, and achieve high temperature oxidation resistance and excellent mechanical properties. Strong, uniform and dense coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

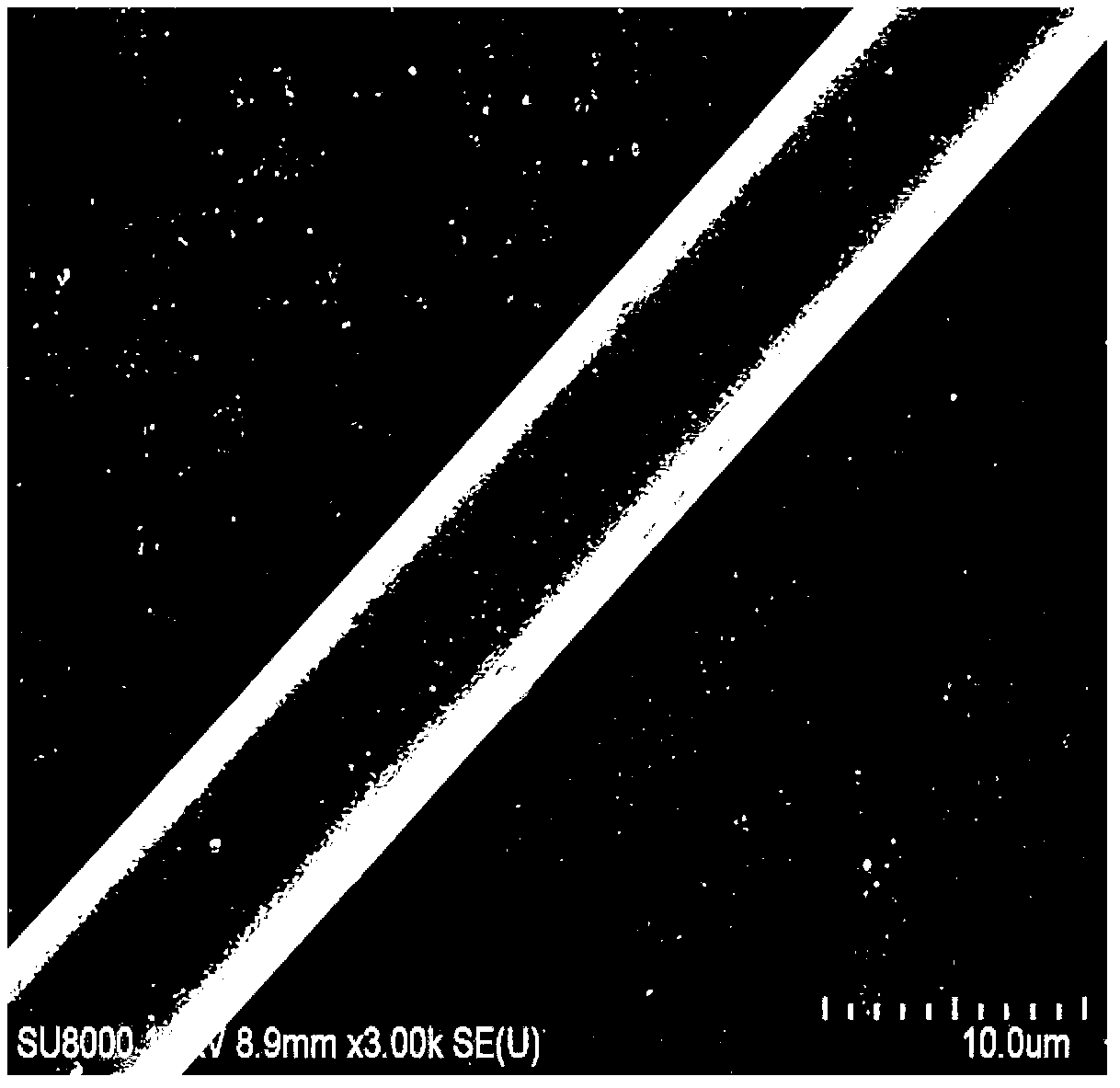

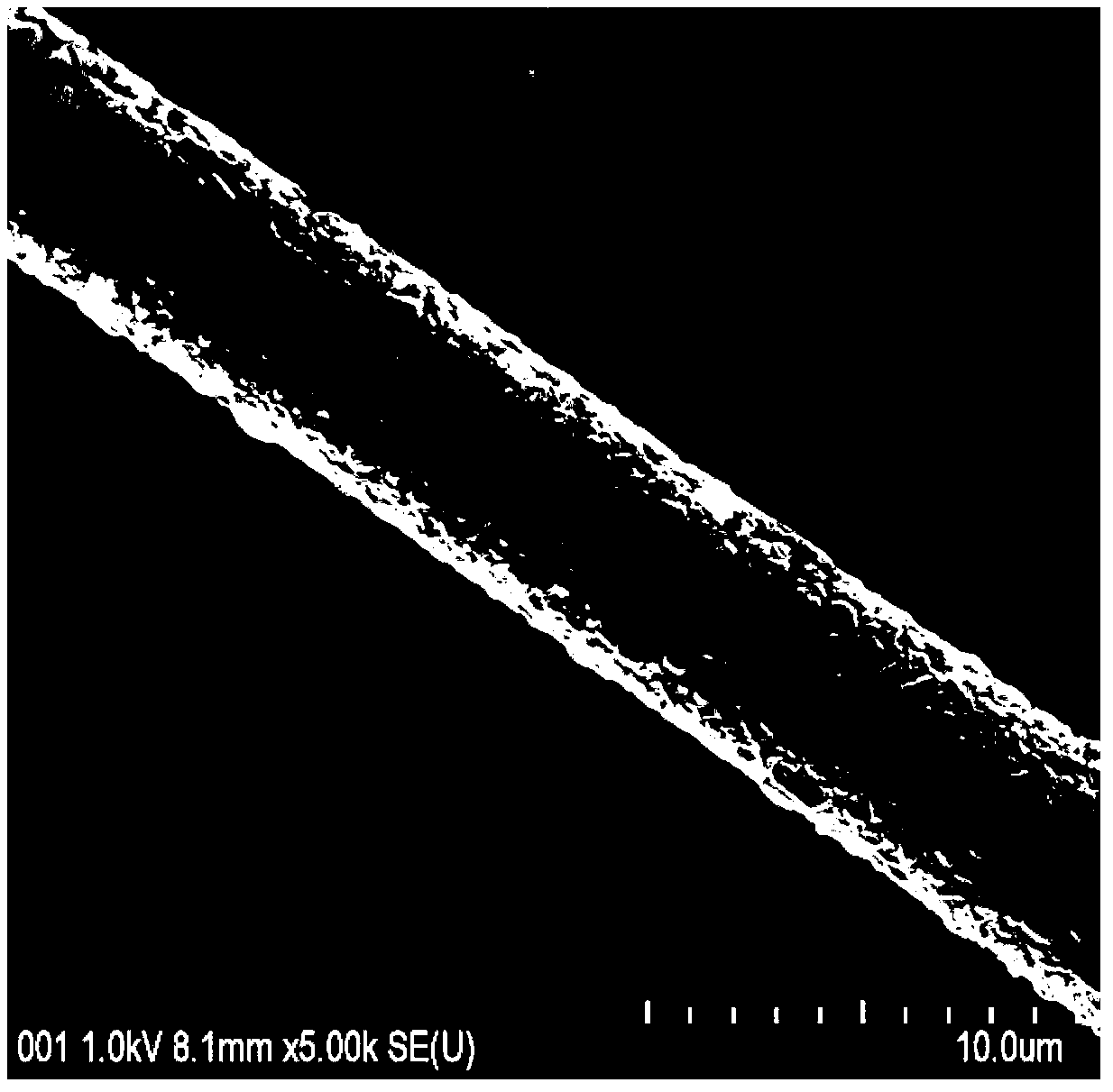

[0024] Prepare a polyborosilazane anhydrous toluene solution with a mass fraction of 0.01%; under a nitrogen atmosphere, put the carbon fiber in a tube furnace at a temperature of 100 ° C for 1 hour; then use a concentration of 40-70% Take it out after soaking in nitric acid for 0.1h, wash it with deionized water and dry it. Under nitrogen atmosphere, put the pretreated carbon fiber into the configured 0.01% polyborosilazane anhydrous toluene solution and immerse it for 0.1 hour, then transfer it to the tube furnace. Under nitrogen flow, the temperature was raised to 100°C at a rate of 0.02°C / min to polymerize and cross-link the carbon fiber, and the temperature was kept at 2 hours; then the temperature was raised to 1000°C at a rate of 0.05 / min for cracking, and after 2 hours of heat preservation, the carbon fiber was heated at 0.05°C / min. The temperature was lowered to 600 °C at a rate of min to obtain SiBN (C) carbon fibers. Its heat-resistant temperature under oxidizing a...

Embodiment 2

[0026] Prepare a polyborosilazane anhydrous toluene solution with a mass fraction of 10%; under a nitrogen atmosphere, put the carbon fiber in a tube furnace at a temperature of 300 ° C for 3 hours; then use a concentration of 40-70% After soaking in nitric acid for 0.5h, take it out, wash it with deionized water and dry it. Under a nitrogen atmosphere, the pretreated carbon fibers were immersed in a prepared 10% polyborosilazane anhydrous toluene solution for 0.5 hours, and then transferred to a tube furnace. Under nitrogen flow, the temperature was raised to 200°C at a rate of 0.2°C / min to polymerize and crosslink the carbon fiber, and the temperature was kept for 4 hours, and then the temperature was raised to 1300°C at a rate of 0.5 / min for cracking. The temperature was lowered to 400°C at a rate of min to obtain SiBN (C) carbon fibers. Its heat-resistant temperature in an oxidative atmosphere is 700°C, and the coating is uniform and dense without micro-cracks.

Embodiment 3

[0028] Prepare a polyborosilazane anhydrous toluene solution with a mass fraction of 20%. Under a nitrogen atmosphere, put the carbon fiber in a tube furnace at 600°C for 6 hours of degumming treatment; then soak it in 40-70% nitric acid for 5 hours, take it out, wash it with deionized water and dry it. Under a nitrogen atmosphere, the pretreated carbon fibers were immersed in a prepared 20% polyborosilazane anhydrous toluene solution for 5 hours, and then transferred to a tube furnace. Under nitrogen flow, the temperature was raised to 400°C at a rate of 2°C / min to polymerize and cross-link the carbon fibers, and the temperature was kept at 6 hours; then the temperature was raised to 1000°C at a rate of 5 / min for cracking, and after 6 hours of heat preservation, the temperature was increased to 5°C / min. The temperature was lowered to 200°C at a rate of min to obtain SiBN (C) carbon fibers. Its heat-resistant temperature under oxidizing atmosphere is 800°C, and the coating is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com