Primer-topcoat water-based paint for container and preparation method thereof

A container and bottom surface technology, applied in coatings, anti-corrosion coatings, etc., can solve problems such as poor water resistance and salt spray resistance, physical injury, and inability to meet people's daily needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

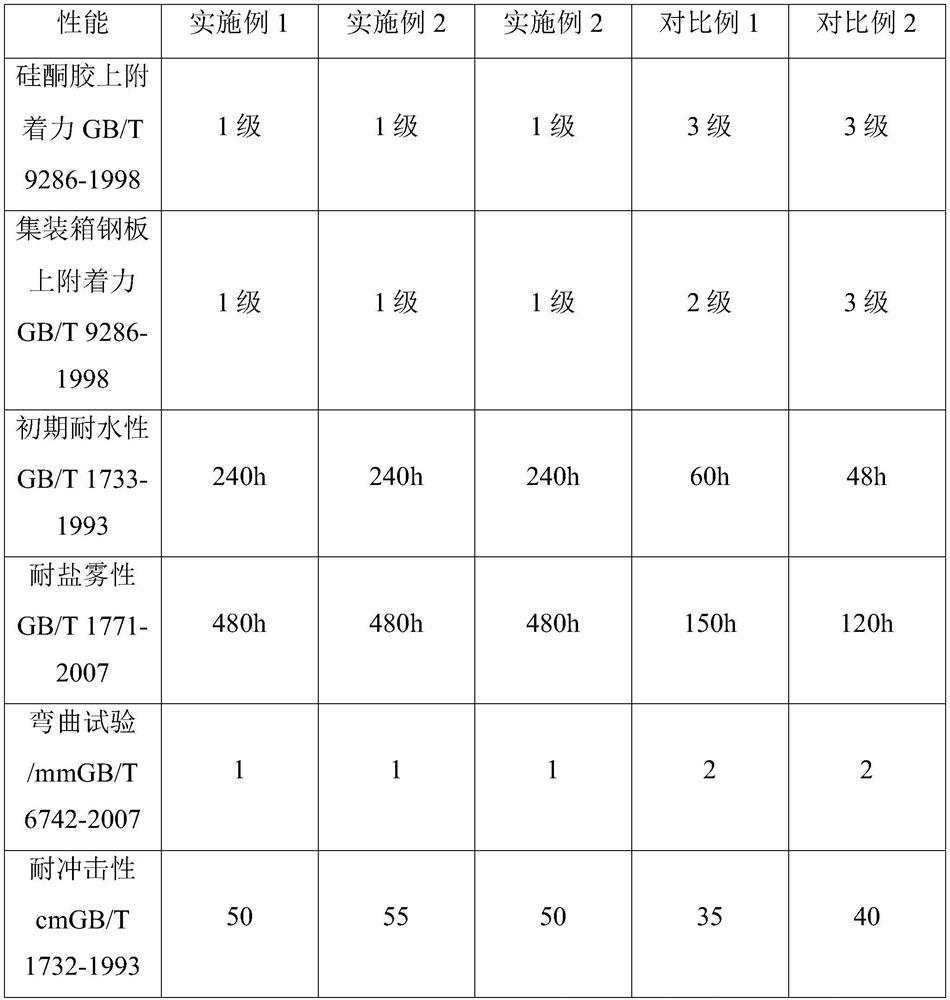

Examples

Embodiment 1

[0039] A kind of bottom-surface all-in-one water paint for containers, comprising the following components in parts by mass:

[0040] DSM’s XK-82 emulsion 45 parts, deionized water 15 parts, propylene glycol 0.5 parts, AMP950.5 parts, BYK’s BYK1900.8 parts, defoamer 0.05 parts, alcohol ester 124 parts, K9N broad-spectrum sterilization 0.05 parts of anti-rust agent, LR-9964 parts of rutile titanium dioxide, 12 parts of anti-rust filler, 0.8 parts of anti-rust additive, 1.5 parts of anti-flash rust agent, 0.8 part of wetting and leveling agent, 0.1 part of organic bentonite and 0.4 parts of thickener share;

[0041] The wetting and leveling agent is composed of Tego100 of Tego and Tego4100 of Tego according to the mass ratio of 1:0.8-1.2;

[0042] The antirust filler is composed of aluminum tripolyphosphate and composite zinc phosphate in a mass ratio of 1:1.8; the composite zinc phosphate is the composite zinc phosphate antirust material of Xiangtan Shuangma Century New Materi...

Embodiment 2

[0052] The invention relates to a bottom-surface all-in-one water paint for containers, comprising the following components in parts by mass:

[0053] 50 parts of XK-82 emulsion from DSM, 20 parts of deionized water, 0.7 parts of propylene glycol, 0.7 parts of AMP950, 1 part of BYK1901 parts of BYK, 0.1 parts of defoamer, 125 parts of alcohol ester, 0.1 parts of K9N broad-spectrum fungicide 1 part, rutile titanium dioxide LR-9965 part, 15 parts of anti-rust filler, 1 part of anti-rust additive, 2 parts of anti-flash rust agent, 1 part of wetting and leveling agent, 0.2 part of organic bentonite and 0.6 part of thickener;

[0054] The wetting and leveling agent is composed of Tego 100 and Tego 4100 in a mass ratio of 1:1;

[0055] The antirust filler is composed of aluminum tripolyphosphate and composite zinc phosphate in a mass ratio of 1:2; the composite zinc phosphate is a composite zinc phosphate antirust material of Xiangtan Shuangma Century New Material;

[0056] The def...

Embodiment 3

[0065] The invention relates to a bottom-surface all-in-one water paint for containers, comprising the following components in parts by mass:

[0066] 55 parts of XK-82 emulsion from DSM in the Netherlands, 25 parts of deionized water, 1 part of propylene glycol, 1 part of AMP95, 1.2 parts of BYK190 from BYK, 0.15 parts of defoamer, 6 parts of alcohol ester 12, K9N broad-spectrum fungicide 0.15 parts, rutile titanium dioxide LR-9966 parts, 18 parts of anti-rust filler, 1.2 parts of anti-rust additive, 2.5 parts of anti-flash rust agent, 1.2 parts of wetting and leveling agent, 0.3 parts of organic bentonite and 0.8 parts of thickener ;

[0067] The wetting and leveling agent is composed of Tego 100 and Tego 4100 in a mass ratio of 1:1.2;

[0068] The antirust filler is composed of aluminum tripolyphosphate and composite zinc phosphate in a mass ratio of 1:2.2; the composite zinc phosphate is a composite zinc phosphate antirust material of Xiangtan Shuangma Century New Materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com