Environment-friendly synthesis method of nitrate

A synthesis method and technology of nitrate, applied in the preparation of nitrate, organic chemistry, etc., can solve the problems of environmental pollution, poor adaptability of raw materials, long production process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

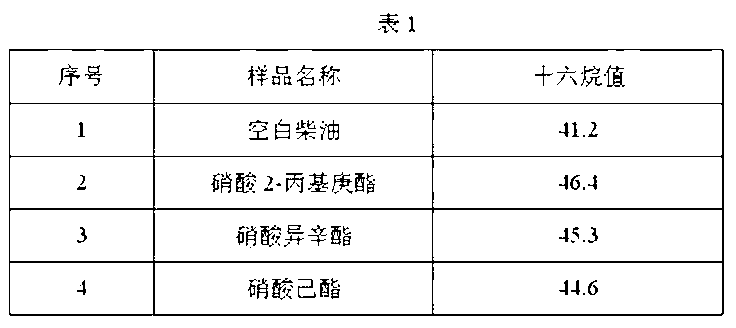

Embodiment 1

[0014] Environmentally friendly nitrate ester synthesis method, first add organic acid and nitric acid as catalysts to the nitration reactor according to the preset dosage percentage to form a mixture, the inside of the nitration reactor is under the protection of nitrogen and the reaction temperature inside the nitration reactor is controlled at 35±3 within the range of ℃, then add alkyl alcohol to the mixture dropwise to carry out nitration reaction, after the nitration reaction, cool the mixed liquid obtained after the reaction to room temperature, then centrifuge the mixed liquid obtained after the reaction to remove the organic acid as a catalyst, and then The mixed liquid from which the organic acid has been removed is subjected to sedimentation and separation to remove the nitric acid in the lower layer, and then the oil layer of the mixed liquid after removing the nitric acid in the lower layer is subjected to alkali washing and pickling to obtain nitrate grease, and the...

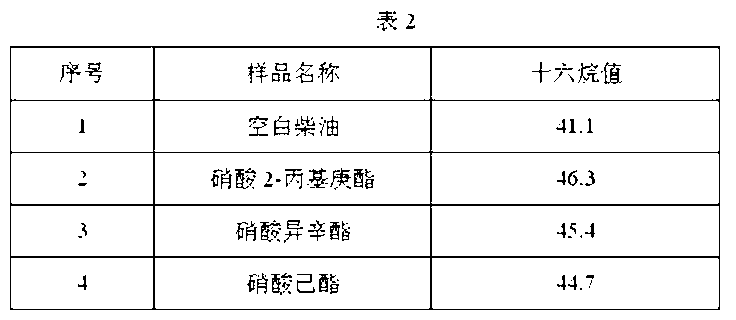

Embodiment 2

[0018] Environmentally friendly nitrate ester synthesis method, first add organic acid and nitric acid as a catalyst to the nitration reactor according to the preset dosage percentage to form a mixture, the inside of the nitration reactor is under the protection of nitrogen and the reaction temperature inside the nitration reactor is controlled at 30 ± 3 within the range of ℃, then add alkyl alcohol to the mixture dropwise to carry out nitration reaction, after the nitration reaction, cool the mixed liquid obtained after the reaction to room temperature, then centrifuge the mixed liquid obtained after the reaction to remove the organic acid as a catalyst, and then The mixed liquid from which the organic acid has been removed is subjected to sedimentation and separation to remove the nitric acid in the lower layer, and then the oil layer of the mixed liquid after removing the nitric acid in the lower layer is subjected to alkali washing and pickling to obtain nitrate grease, and ...

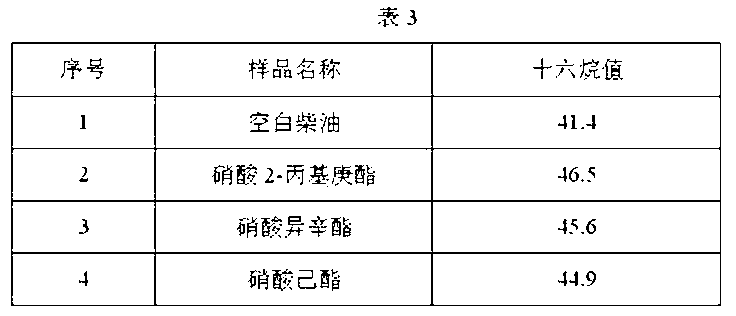

Embodiment 3

[0022] Environmentally friendly nitrate ester synthesis method, first add organic acid and nitric acid as catalysts to the nitration reactor according to the preset dosage percentage to form a mixture, the inside of the nitration reactor is under the protection of nitrogen and the reaction temperature inside the nitration reactor is controlled at 40 ± 3 within the range of ℃, then add alkyl alcohol to the mixture dropwise to carry out nitration reaction, after the nitration reaction, cool the mixed liquid obtained after the reaction to room temperature, then centrifuge the mixed liquid obtained after the reaction to remove the organic acid as a catalyst, and then The mixed liquid from which the organic acid has been removed is subjected to sedimentation and separation to remove the nitric acid in the lower layer, and then the oil layer of the mixed liquid after removing the nitric acid in the lower layer is subjected to alkali washing and pickling to obtain nitrate grease, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com