Preparation method of sun-screening agent iso-octyl p-methoxycinnamate

A technology of methoxycinnamic acid and p-methoxybenzaldehyde, applied in the field of daily chemical industry, can solve the problems of high equipment material and safety requirements, loss of raw materials, and high reaction temperature, so as to solve the problem of low quality and reduce waste water. The effect of producing and reducing the degree of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

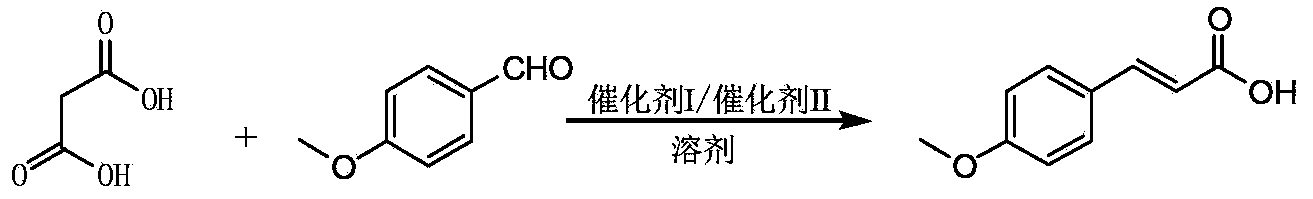

Method used

Image

Examples

Embodiment 1

[0044] Add 68kg p-methoxybenzaldehyde, 300kg toluene, 58Kg malonic acid, 2Kg piperidine and 1.41Kg acetic acid in the reaction kettle, heat up to reflux, react at a reaction temperature of 108-110°C, and continuously separate out the reaction produced Water, react for 4.5 hours to complete the reaction, directly lower the temperature to 10°C, filter with suction, and use the filtrate for the next batch; the filter cake is dried at 80°C, the HPLC content is 99.5%, and the yield is 96%. GS-MS analysis molecular weight is 178, by 1 H-NMR detection confirmed that it was p-methoxycinnamic acid.

Embodiment 2

[0046] Add 68kg p-methoxybenzaldehyde, 350kg toluene, 58Kg malonic acid, 2Kg piperidine and 1.41Kg acetic acid in the reaction kettle, heat up to reflux, react when the reaction temperature is 108-110°C, and continuously separate out the reaction produced Water, reacted for 5.0h to complete the reaction, directly cooled to 12°C, suction filtered, and the filtrate was used for the next batch; the filter cake was dried at 80°C, the HPLC content was 99.2%, and the yield was 95.6%. 1 H-NMR detection confirmed that it was p-methoxycinnamic acid.

Embodiment 3

[0048] Add 68kg p-methoxybenzaldehyde, 250kg toluene, 58Kg malonic acid, 2Kg piperidine and 1.41Kg acetic acid in the reaction kettle, heat up to reflux, react when the reaction temperature is 110-112°C, and continuously separate out the reaction produced water, reacted for 4 hours to complete the reaction, directly lowered the temperature to 8°C, and suction filtered, and the filtrate was used for the next batch; the filter cake was dried at 80°C, the HPLC content was 99.4%, and the yield was 93.5%. 1 H-NMR detection confirmed that it was p-methoxycinnamic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com