Automobile suspension support arm and production method thereof

A technology for supporting arms and automobiles, which is applied in the direction of cantilevers, suspensions, and vehicle parts installed on pivots, which can solve the problems of low machining accuracy, difficult safety, reliability, and difficult manufacturing, and achieve structural distribution Reasonable, simple processing and forming methods, good weld fusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

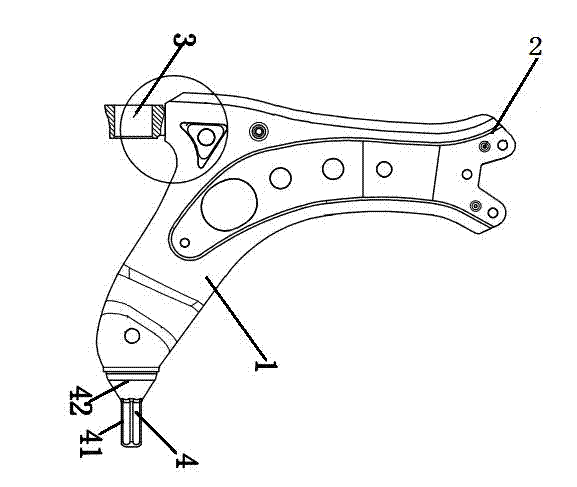

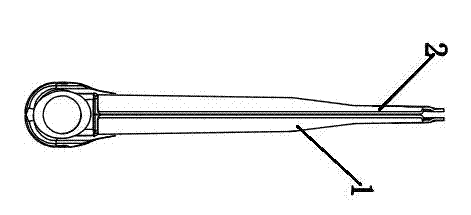

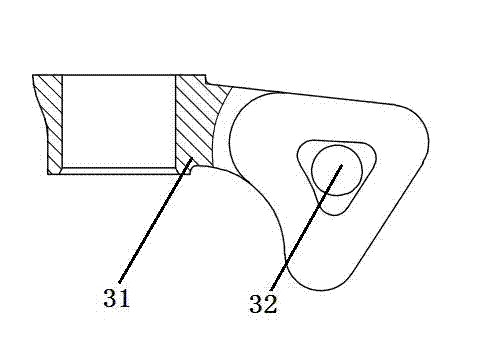

[0020] As shown in Embodiments 1-3, this embodiment relates to an automobile suspension support arm, which includes: a first bracket 1, a second bracket 2, a bushing assembly 3 and a gun head 4, and the bushing assembly 3 includes a bushing The sleeve 31 and the connecting end 32; the preparation method of the automobile suspension support arm mainly includes the following steps: stamping and forming of the bracket—punching the mounting hole of the bracket—assembly and welding of the bracket—assembly and welding of the gun head—electrophoretic coating. The bracket assembly and welding process: the connecting end of the bushing is a triangular connecting end, and the corresponding first bracket and the second bracket are provided with triangular holes, and the triangular connecting end of the bushing assembly is set on the between the triangular holes on the first bracket and the second bracket and are fixed between the first bracket and the second bracket by rivets, wherein the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com