Glass screen and foamed plastic integrated forming display and processing method thereof

A foamed plastic and display technology, which is applied in the direction of instruments, identification devices, etc., can solve the problems affecting the combination of molded plastics and glass screens, and achieve the effects of good heat insulation, long service life, and firm adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

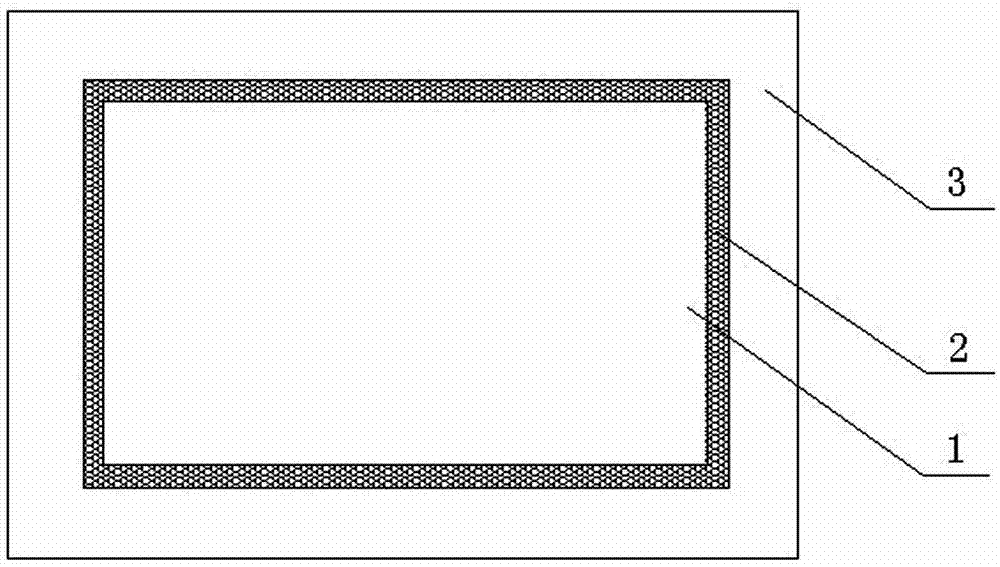

[0015] In order to further reveal the technical solutions of the present invention, the following describes the implementation of the present invention in detail in conjunction with the accompanying drawings: figure 1 As shown, the display in which a glass screen and foamed plastic are integrally formed includes a glass screen 1, and a fine hole 2 is provided on the edge of the glass screen 1, and the diameter of the fine hole 2 is 0.2-0.4 mm. The glass screen 1 is integrally formed with a foamed plastic 3, and the foamed plastic 3 is thermoplastic foamed resin.

[0016] processing methods:

[0017] a. Use external pressure equipment, use gas injection, and foam the foamed plastic that dissolves at high temperature through an exclusive screw;

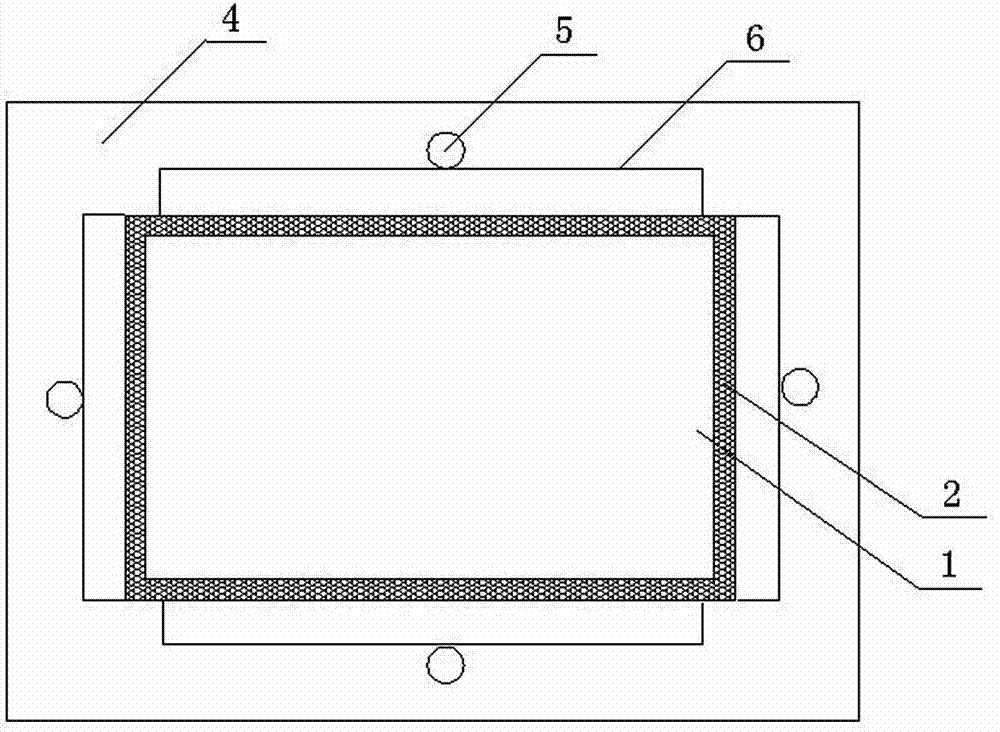

[0018] b. If figure 2 As shown, the glass screen 1 with fine holes 2 on the edge and the related electronic components installed is placed in the set metal mold cavity 4, and after the foamed plastic is foamed under the corresponding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com