Gas-solid phase catalytic reactor

A catalytic reactor, gas-solid phase technology, used in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as large resistance, large bed resistance, and low volume utilization, and achieve easy manufacturing and maintenance. The effect of increased reliability and enhanced heat transfer capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

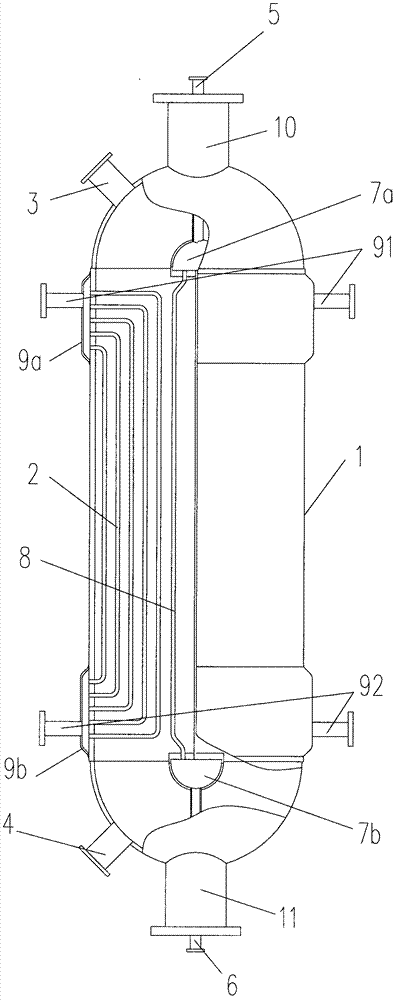

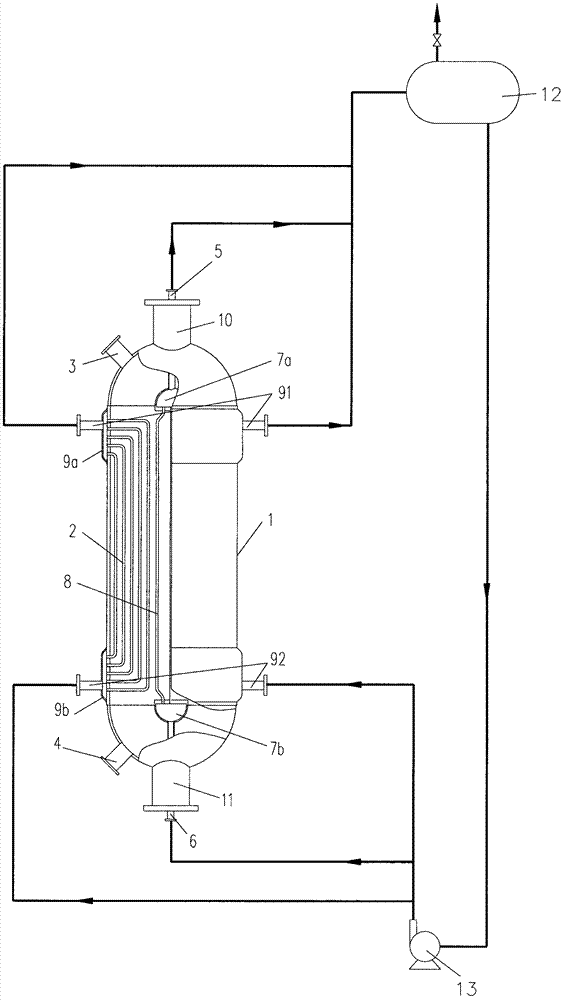

[0024] Such as figure 1 The gas-solid phase catalytic reactor shown includes a shell 1 and heat exchange internals, the top of the shell is provided with an air inlet 3 and a manhole 10, and the bottom of the shell is provided with an air outlet 4 and a catalyst discharge port 11. The heat exchange internal parts include a number of bent heat exchange tubes 2 and a central heat exchange tube group. The two ends of the heat exchange tubes 2 are respectively connected to the upper inner wall and the lower inner wall of the shell, and the outer wall of the shell at the connection is An outlet jacket 9a and an inlet jacket 9b are respectively provided, and the outlet jacket 9a and the inlet jacket 9b are single annular jackets arranged around the cylinder wall, and the outlet jacket 9a is provided with two symmetrically distributed changing The heat medium outlet 91 and the inlet jacket 9b are provided with two symmetrically distributed heat exchange medium inlets 92 .

[0025] T...

Embodiment 2

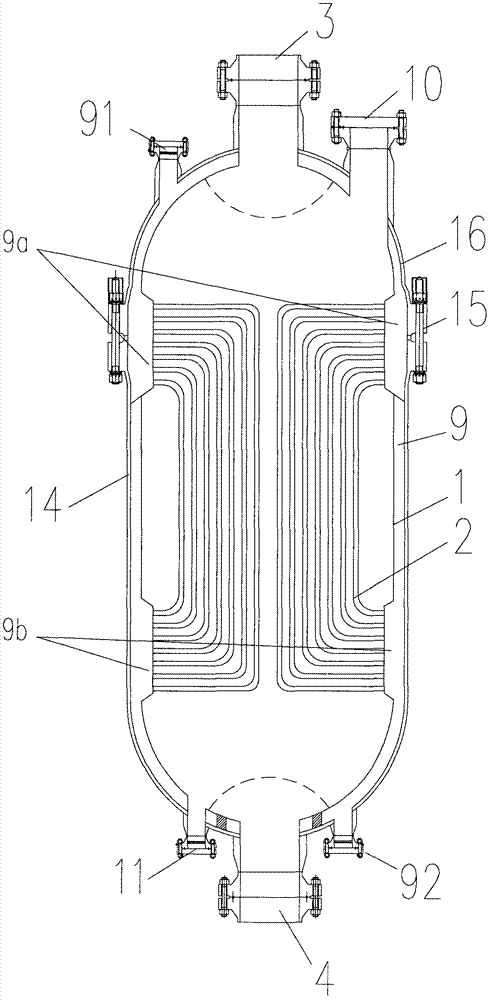

[0028] Such as image 3 The gas-solid phase catalytic reactor shown includes a shell 1 , heat exchange internals and a shell 14 with an upper head 16 , and the upper head 16 and the shell 14 are connected by a flange 15 . The heat exchange medium jacket 9 is formed between the shell 1, the outer shell 14 and the upper head 16. The top of the reactor is provided with an air inlet 3, a heat exchange medium outlet 91 and a manhole 10, and the bottom of the reactor is provided with an outlet. Air port 4, heat exchange medium inlet 92 and catalyst discharge port 11. The heat exchange inner parts include a plurality of heat exchange tubes 2 with both ends bent, and the two ends of the heat exchange tubes 2 are respectively connected to the upper inner wall and the lower inner wall of the shell, and the shell at the joint is concave inward, forming The outlet jacket 9a and the inlet jacket 9b, the lower part of the outlet jacket 9a is closed, so that the area where the inlet jacket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com