Anastomat for gastrointestinal tract anastomosis surgery and production method thereof

A stapler and gastrointestinal tract technology, applied in the field of medical devices, can solve the problems of increasing the scarring of the anastomosis, narrowing and obstruction of the intestinal lumen, unfavorable intestinal peristalsis, and reducing the elasticity of the gastrointestinal tract, etc., so as to improve the success rate of surgery, Effect of reducing wound infection and reducing treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

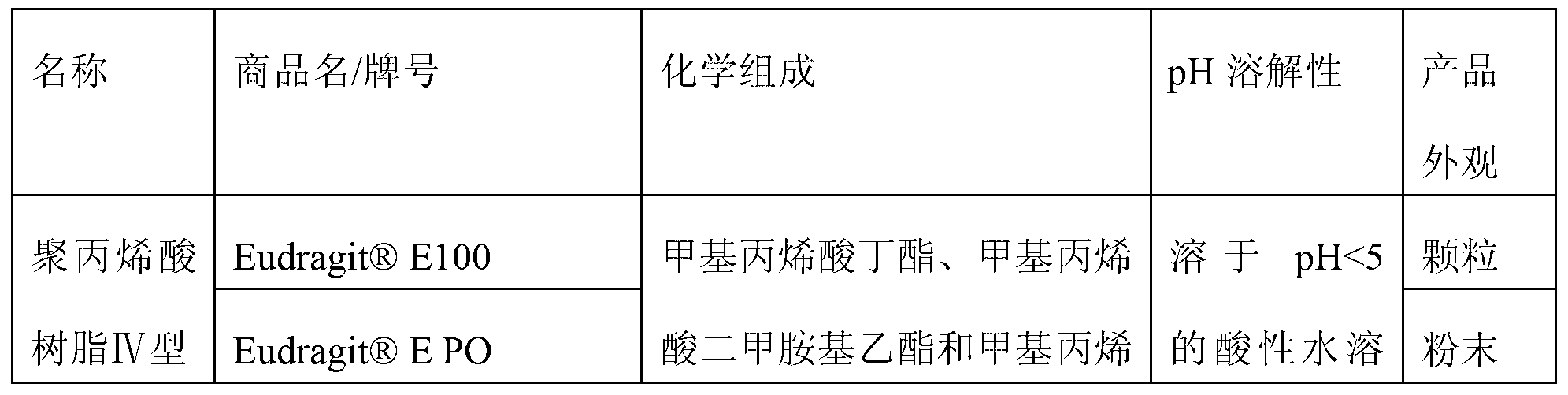

[0070] The present invention also provides a method for preparing the stapler, characterized in that the stapler is melt-injected under the following conditions: the mold preheating temperature is 35-65°C, preferably 40-60°C, more preferably 45-55°C ℃; injection molding temperature is 215-235 ℃, preferably 220-230 ℃; injection pressure is 800-1200 bar, preferably 900-1100 bar; molding pressure is kept at 500-900 bar, preferably 650-800 bar; holding time is 2-8 seconds, preferably 3-6 seconds.

[0071] The gastrointestinal tract stapler provided by the invention has antibacterial, anti-inflammatory and hemostatic effects, and can be applied to drugs such as sulfonamides, quinolones, Anluoxue, and hemostasis. Drugs such as sulfonamides and quinolones have broad-spectrum antibacterial properties and can weaken or reduce postoperative inflammation of the gastrointestinal tract. Hemostatic drugs such as Anluoxue and Zhixuemin can reduce the permeability and fragility of capillarie...

preparation example 1

[0082] Preparation example 1, raw material preparation

[0083] Preparation of polyglycolide: Add 500 g of glycolide into the reactor, and add 0.005% (weight ratio) of stannous octoate catalyst into the reactor. The reaction system was sealed, and nitrogen gas was introduced to protect the reaction. The temperature of the reaction system was controlled at 120° C., and the reaction was carried out for 30 hours. The reactants were chopped to make pellets with a particle size of 1-8 mm, and 491 g of pellets were obtained by weighing, with a yield of 98.2%. The above pellets were dissolved in hexafluoroisopropanol solution, and the intrinsic viscosity of the polymer was measured as 3.28 dL / g by Ubbelohde viscometer in a constant temperature water bath at 25°C.

[0084] Preparation of raw materials for injection molding: 491 g of polyglycolide was packaged for use.

preparation example 2

[0085] Preparation example 2, raw material preparation

[0086] Preparation of polyglycolide: According to the method of preparation example 1, except that the reaction time was changed to 25 hours, 495 g of polyglycolide was prepared with a yield of 99%. According to the method of Preparation Example 1, the intrinsic viscosity of the polymer is 3.15 dL / g.

[0087] Preparation of injection molding raw materials: Mix 495g of polyglycolide and 26g of medical grade barium sulfate (ratio 95:5) evenly, and package for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com