Method for detecting the operational readiness of a jump lambda sensor

一种运行准备、探测器的技术,应用在仪器、机械设备、测量装置等方向,能够解决识别滞后等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

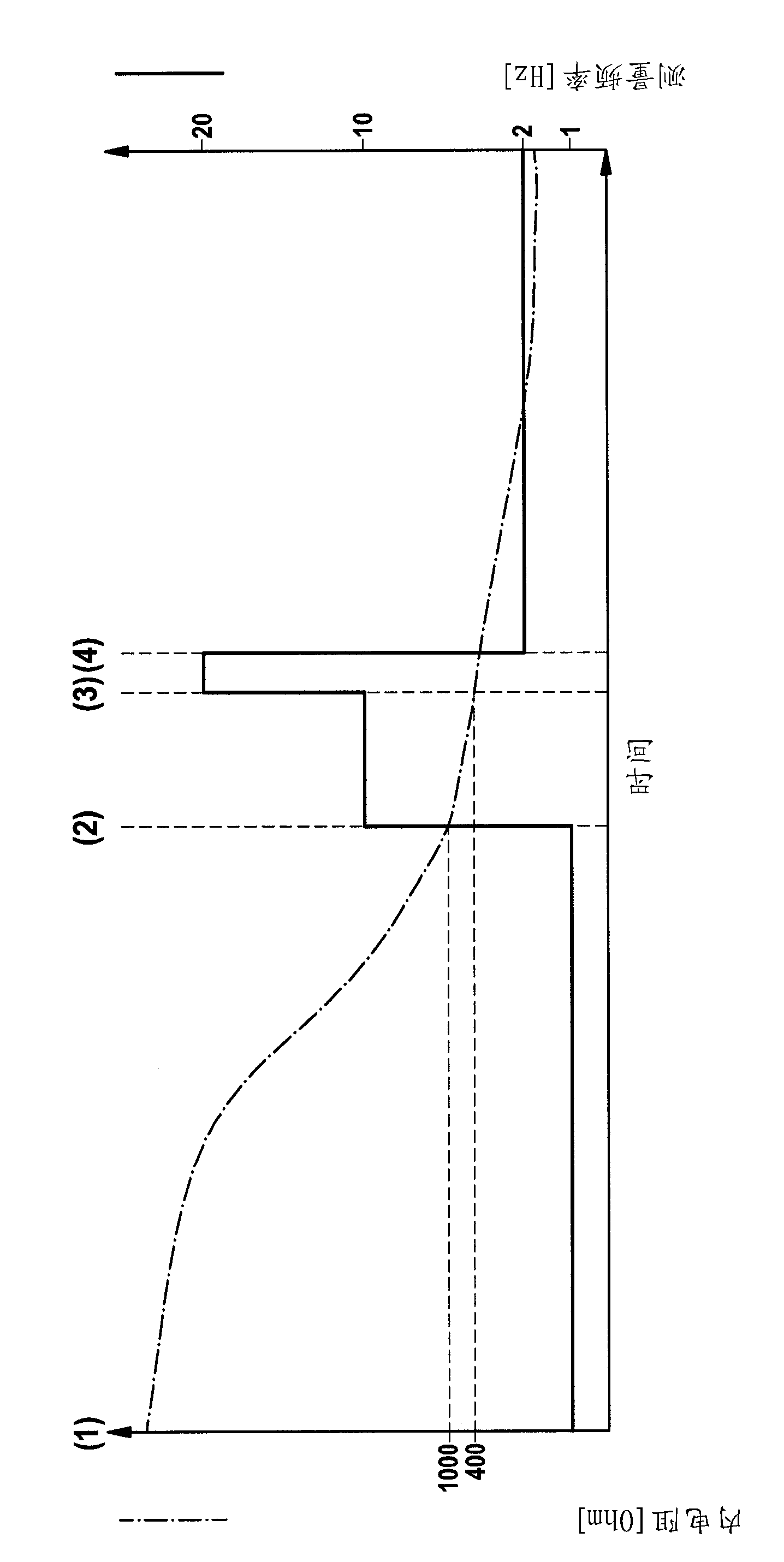

[0027] The method according to the invention uses the internal resistance of the step lambda detector as a criterion for recognizing that the detector is ready for operation. There is a clear correlation between the detector internal resistance and the detector element temperature, wherein the detector element temperature exceeds a certain temperature threshold when the detector internal resistance simultaneously falls below a corresponding resistance threshold. The operational readiness of the detector is reached when the internal resistance of the detector falls below a certain threshold value. According to the invention, the internal resistance of the probe is already measured before the probe is ready for operation. The attainment of the operational readiness of the detector can be detected without delay only by measuring before the operational readiness of the detector. The internal resistance of the detector is measured by applying a pulsating current to the detector. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com