Nonlinear fault detection method based on semi-supervised manifold learning

A manifold learning and fault detection technology, applied in the testing of machines/structural components, measuring devices, instruments, etc., can solve problems such as unsupervised, underutilized label sample category information, etc., to achieve improved reliability and good generalization The effect of ability, fast learning and training speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further illustrate the technical solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

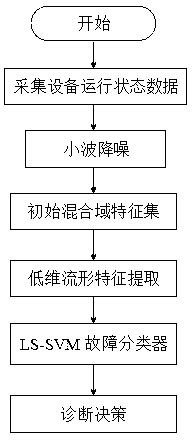

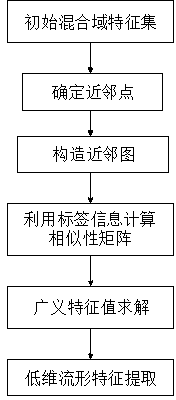

[0014] Such as figure 1 As shown, a kind of non-linear fault detection method based on semi-supervised manifold learning proposed by the present invention, by extracting the nonlinear geometric manifold feature of the signal data collected by the device, detects the fault category of the operating state of the device. The method is divided into the following three Steps are carried out.

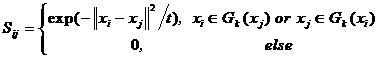

[0015] Step 1: Collect and preprocess the operating state signal data of the monitoring electromechanical equipment, and obtain a sample set representing the operating state of the equipment through mixed-domain feature extraction to form an initial feature space. Its initial mixed-domain feature sample set is constructed as follows: (1) collect multi-channel vibration signal dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com