Method for detecting and representing morphology features of print of metal conducting wires on transparent base materials

A technology of metal wires and transparent substrates, applied in measuring devices, instruments, optical devices, etc., can solve problems such as deviation, reduction of electrical properties of wires and components, and achieve the effect of ensuring accuracy and improving resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the object, technical solution and effect of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

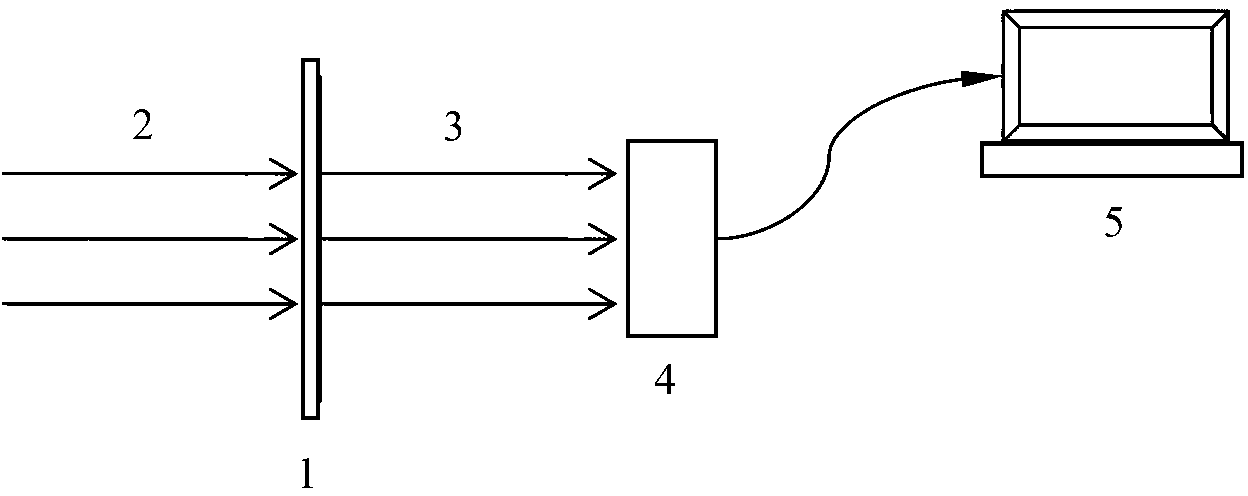

[0045] refer to figure 1 , is a schematic diagram of the optical path and main component units of the transmission image of the wire imprinted sample of the present invention. Including imprinted sample 1, vertical incident light 2 formed by illuminating white light path, transmitted light 3 formed after passing through imprinted sample, CCD imaging device 4, and computer and control software (computer control system) 5 connected to CCD device.

[0046] figure 1 The specific requirements and process of the detection and characterization of the metal wire imprint morphology features of the system shown are as follows:

[0047] The spectral energy distribution of the illuminating white light should be relatively balanced, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com