A method for raising and maintaining the vacuum degree of a vacuum chamber

A technology for maintaining vacuum and vacuum chamber, which is applied in the field of improving and maintaining the vacuum degree of vacuum chamber by using TEC refrigerator to refrigerate molecular sieves. It can solve the problems of ion pump damage, inability to power off, and large outgassing, etc., to improve Cooling efficiency, save cooling energy, and prevent heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

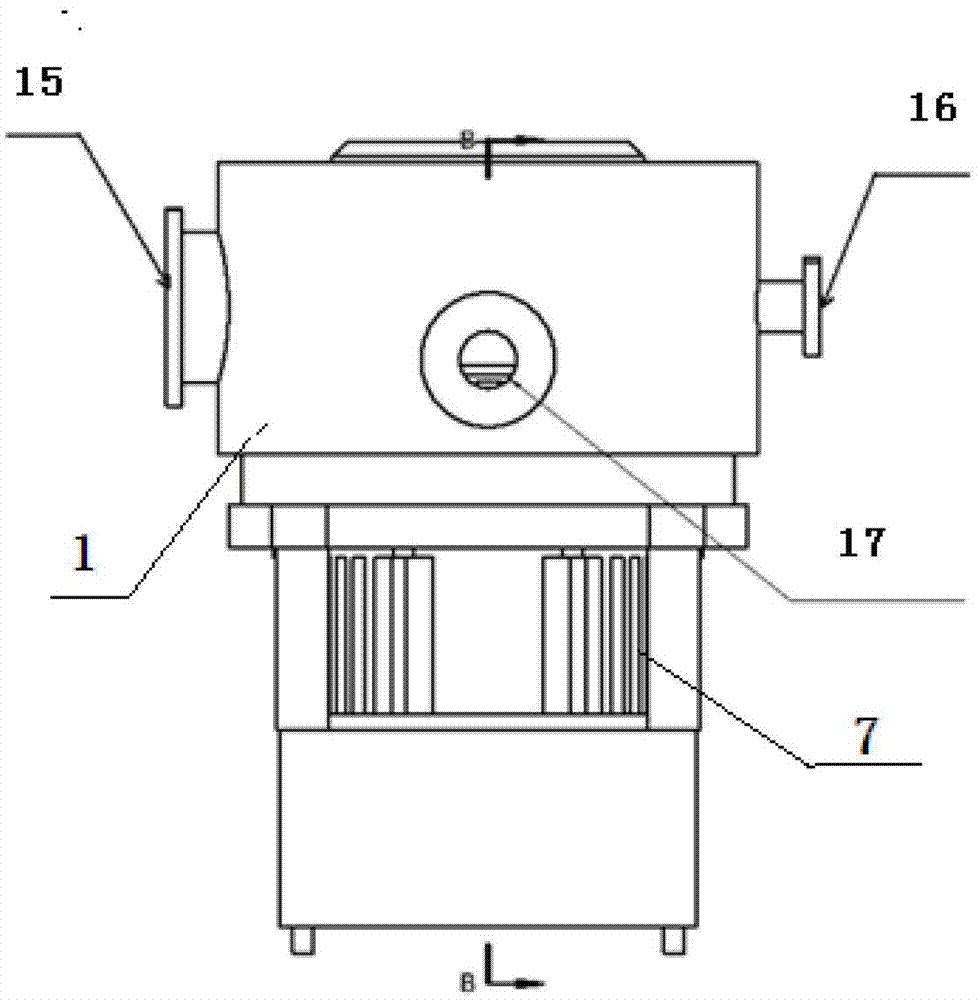

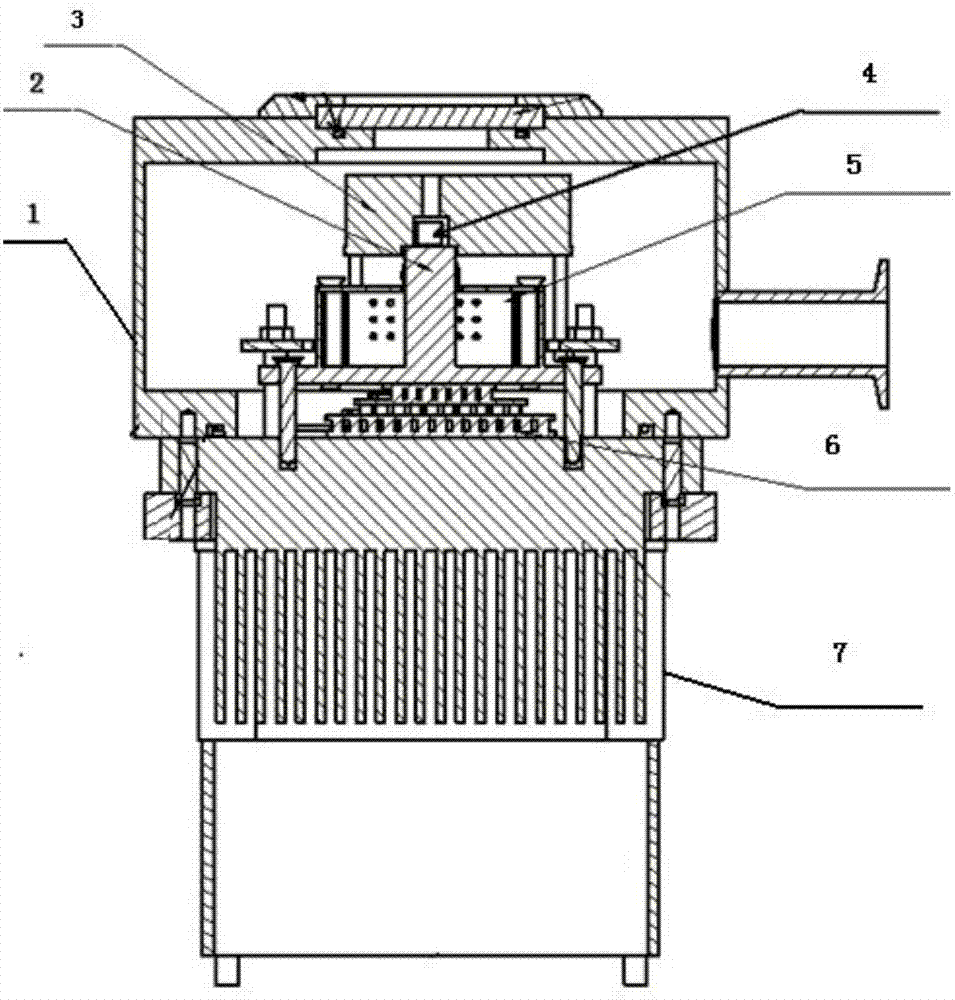

[0028] Such as figure 2 , 3 As shown, this embodiment includes a vacuum chamber 1, a CCD detector 3, a TEC refrigerator, an air-cooled heat dissipation system 7, and a molecular sieve 5, and the TEC refrigerator adopts a three-stage TEC refrigeration sheet 6;

[0029] Such as image 3 As shown, the cold end of the three-stage TEC refrigeration sheet 6 conducts thermal conduction with the molecular sieve 5 and the CCD detector 3 respectively through the cold finger 2, the cold end of the TEC refrigerator gives deep cooling to the molecular sieve, and the hot end and the air-cooled heat dissipation system 7. Thermal conduction for strong heat dissipation to ensure TEC cooling efficiency. One end of the cold finger 2 is in contact with the bottom of the CCD detector 3 , and the other end is in contact with the cold end of the tertiary TEC cooling sheet 6 . The molecular sieve 5 is fixedly arranged on the cold finger 2 . One end of the cold finger 2 close to the CCD detector ...

Embodiment 2

[0038] The difference between this embodiment and Embodiment 1 is that the heat at the hot end of the TEC refrigerator can be taken away by a water-cooled heat dissipation system, that is, a water-cooled heat dissipation system is connected to the lower end of the heat sink 11 (figure omitted); firstly, the vacuum chamber 1 When the vacuum degree is pumped to above 10E-4mbar, the TEC refrigerator is energized to work, and the cold end of the TEC refrigerator is cooled to the lowest possible temperature by the molecular sieve that is thermally connected to it. After the molecular sieve is strongly adsorbed, close the vacuum chamber suction valve , stop vacuuming.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com