Low-temperature refrigerator device structure

A device structure and low-temperature cold storage technology, which is applied to household refrigeration devices, coolers, refrigeration plants, etc., can solve the problems of increased heat transfer temperature difference, low refrigeration efficiency, energy consumption efficiency, etc., to improve earthquake resistance and save refrigeration energy , Increase the effect of civil construction investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

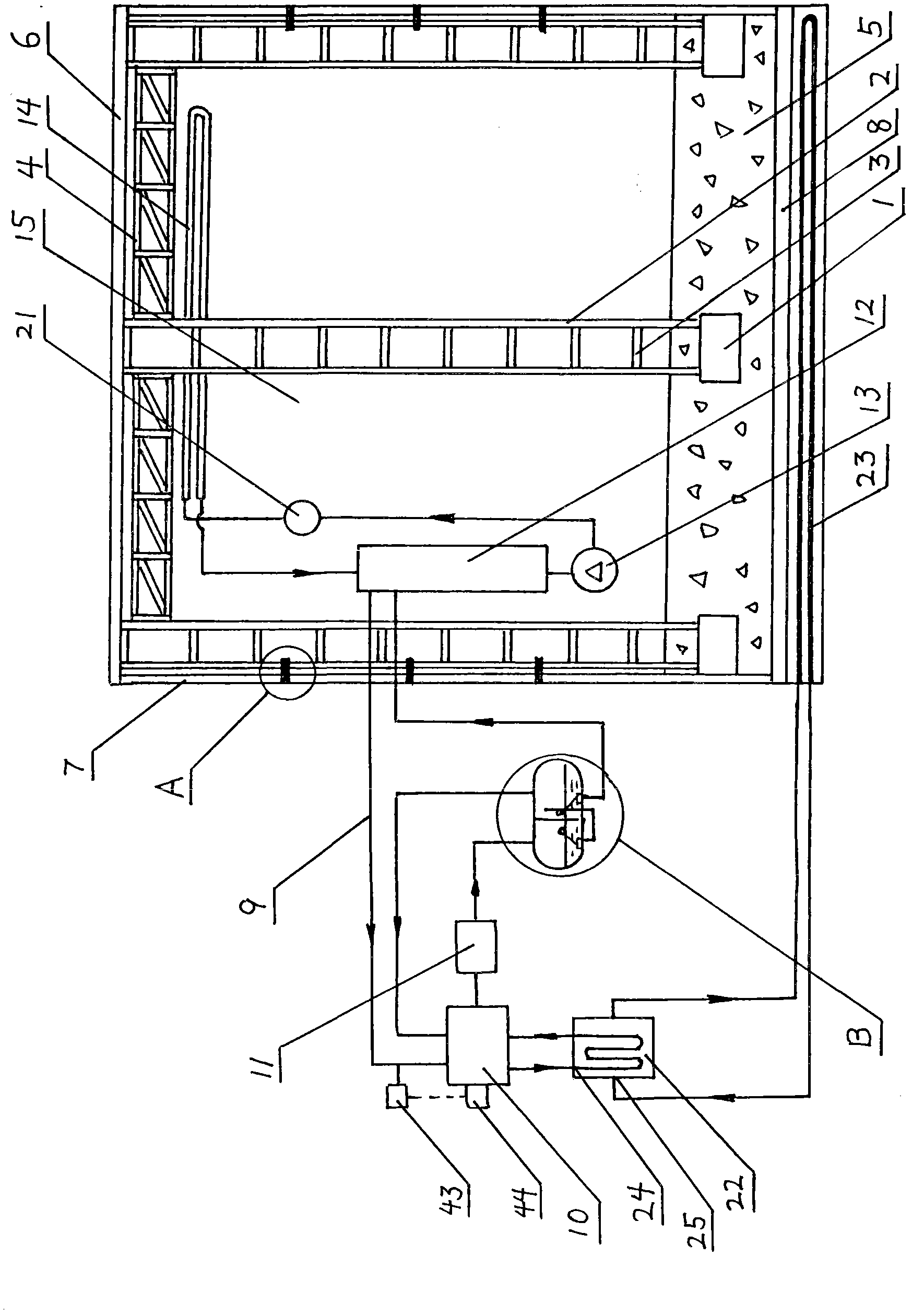

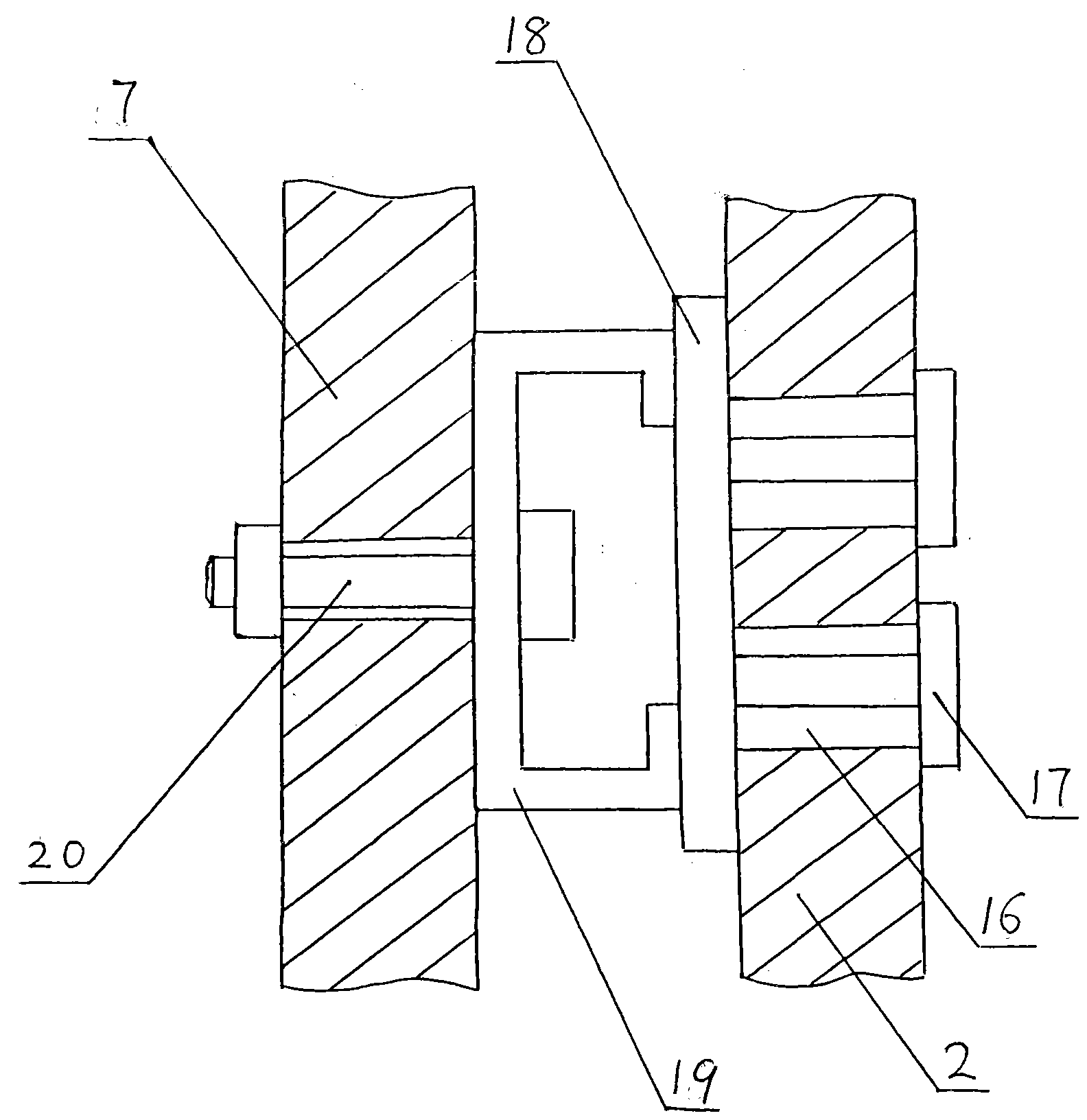

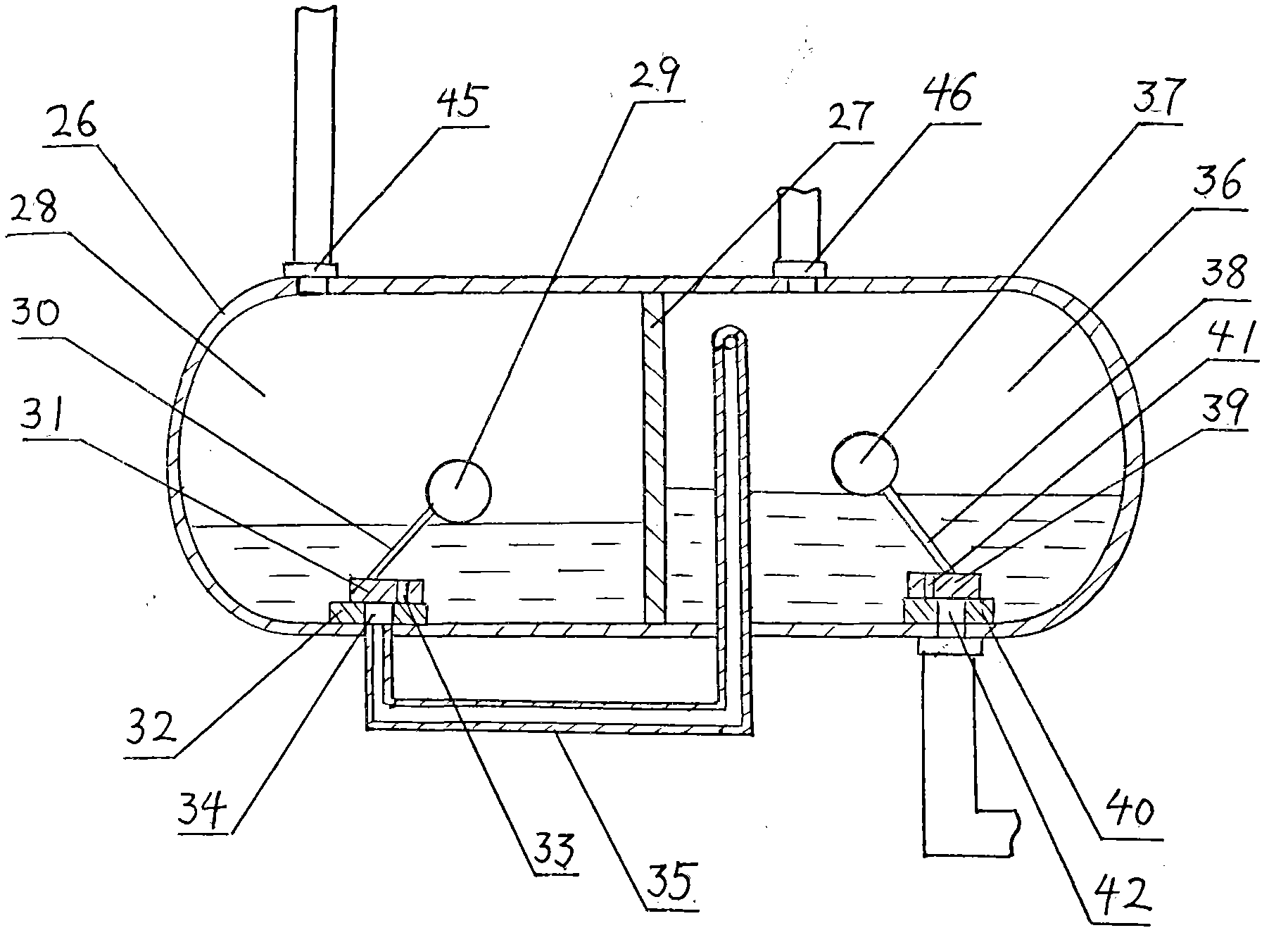

[0032] Such as figure 1 , figure 2 , image 3As shown, the low-temperature cold storage device structure of the present invention consists of embedded parts 1, supporting steel columns 2, steel column shelf connectors 3, supporting steel column connectors 4, raft foundation 5, upper insulation board 6, side The insulation board 7, the bottom insulation board 8, the refrigerant pipeline 9, the compressor 10, the condenser 11, the refrigerant circulation barrel 12, the refrigerant circulation pump 13, and the evaporation pipe 14, and the embedded parts 1 Installed on the lower part of the supporting steel column 2; connect the supporting steel column 2 with the steel column shelf connector 3; connect the supporting steel column connector 4 at the top of the supporting steel column 2; The embedded part 1 of the anchor is installed in the raft foundation 5; the upper insulation board 6 is installed on the support steel column 2, and the side insulation panel 7 is installed outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com