Reinforcement layer with variable damping

A reinforcement layer and damping technology, which is applied to building components, earthquake resistance, etc., can solve problems such as difficult to present, structural damage or even collapse, and the stiffness of the reinforcement layer should not be too large, so as to reduce internal force, improve lateral stiffness, wind resistance and earthquake resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

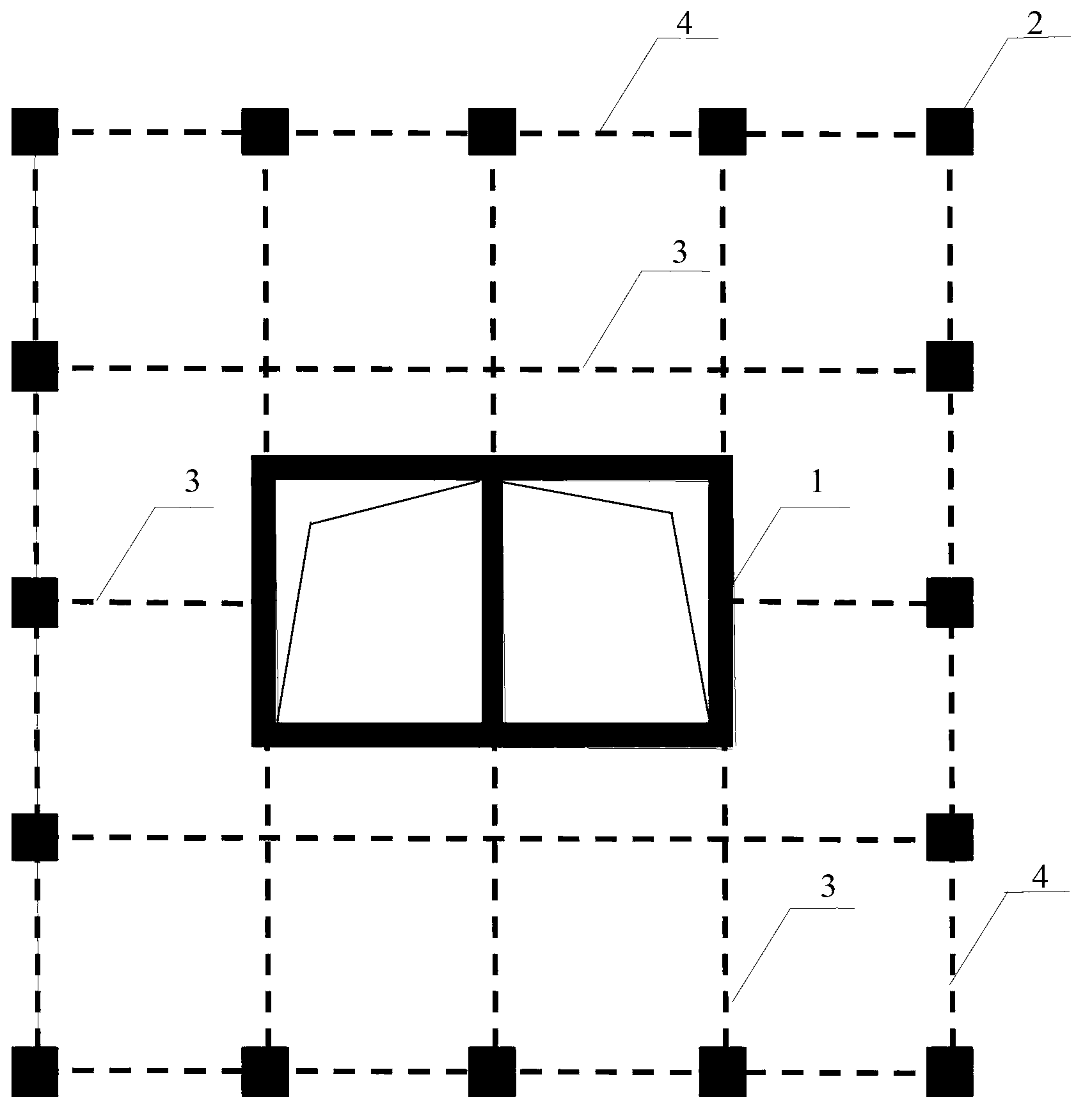

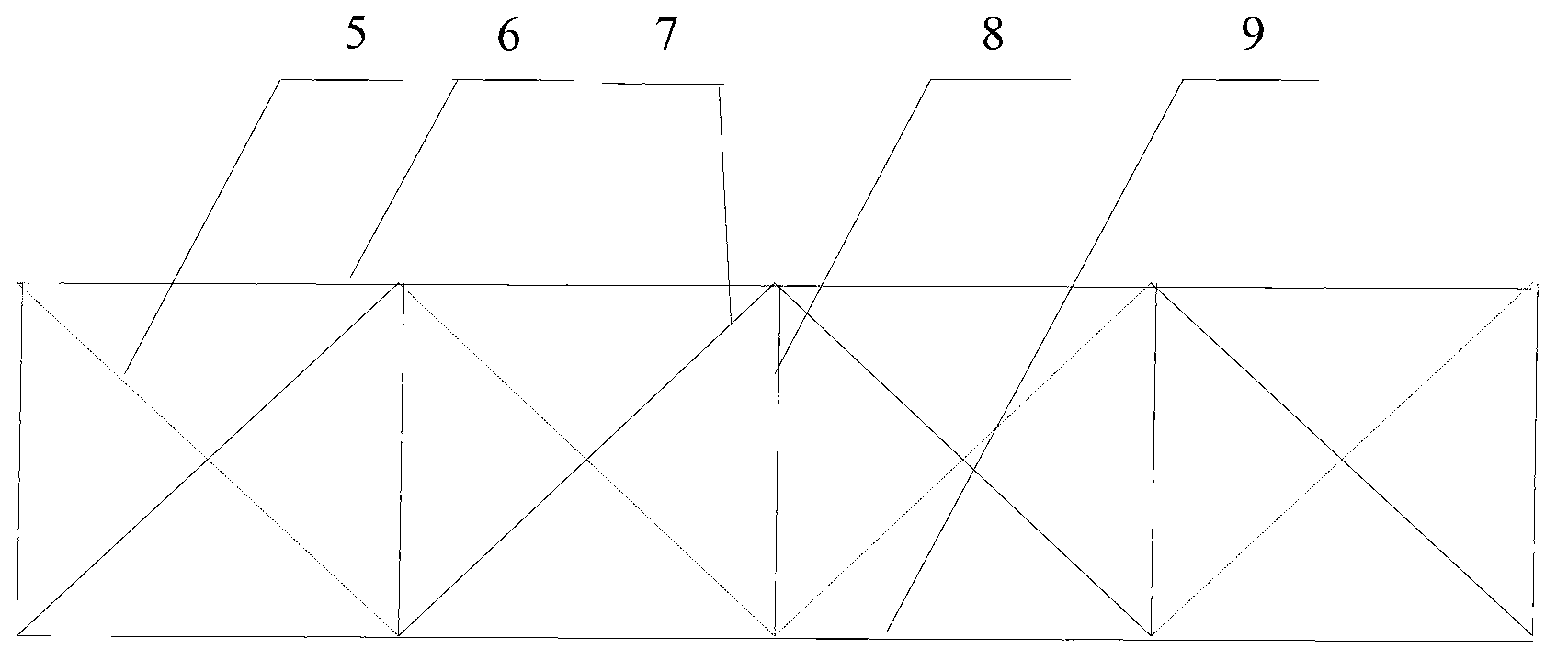

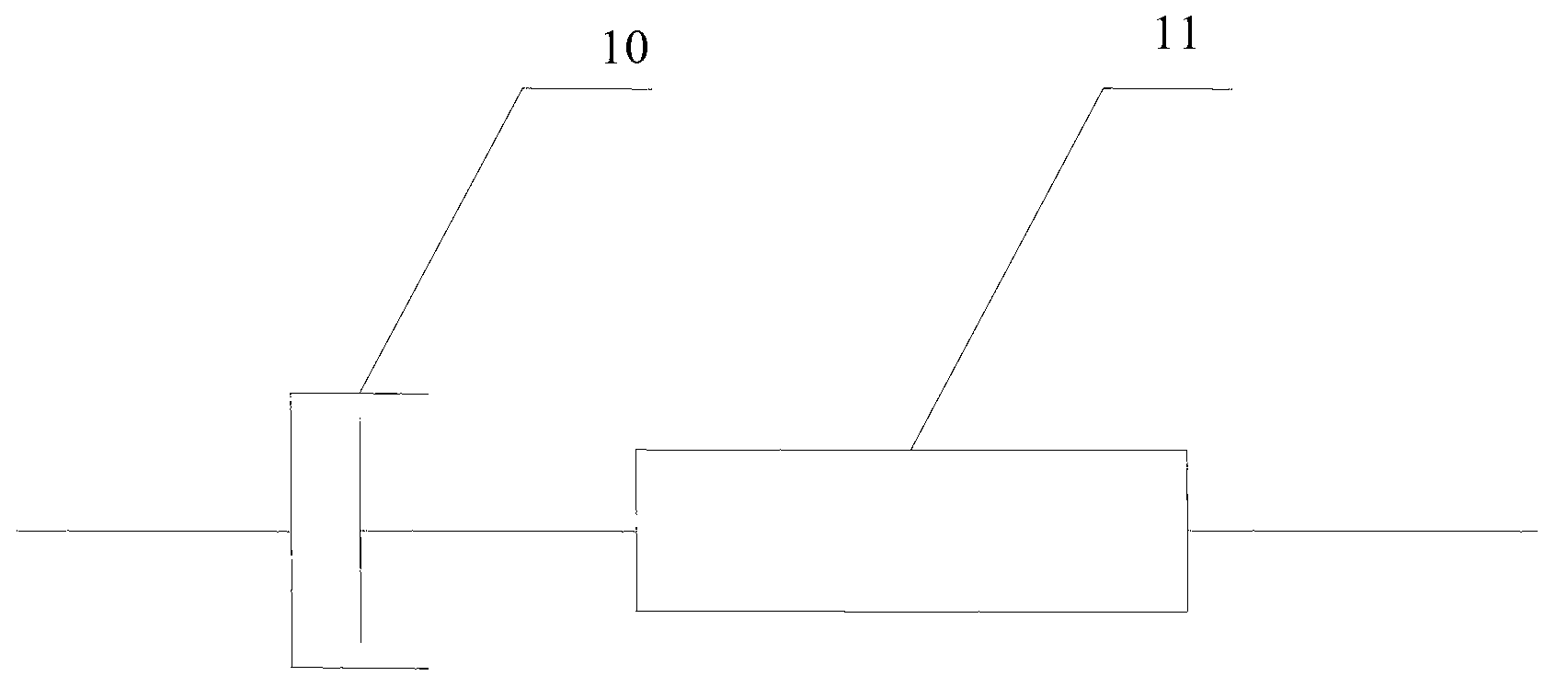

[0019] Such as figure 1 As shown, a reinforced layer with variable damping is designed to improve the lateral stiffness, wind resistance and seismic performance of the structure. The system includes a core tube 1 set in the middle of the building and a number of frame columns 2 set on the periphery of the building. The outrigger truss 3 is connected between the core tube 1 and the frame column 2 and is perpendicular to the frame column 2.

[0020] Multiple outrigger trusses 3 form a grid structure. A hoop truss 4 is arranged around a plurality of frame columns 2 . In practical applications, sometimes only the outrigger truss 3 is provided, and the hoop truss 4 is not provided. The purpose of the outrigger truss 3 is to increase the axial force of the frame column 2, so that the anti-overturning moment of the frame is also improved, thereby ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com