Expansive soil improved by waste straw ash and marble ash and preparation method and application thereof in construction

A marble ash and waste straw technology, applied in the application, chemical instruments and methods, fertilization devices and other directions, can solve the problems of low content of modifiers, low strength, large amount of alkali slag, etc., to improve shear strength and durability, The effect of increasing frictional resistance and improving shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of expansive soil improved with waste straw ash and marble ash comprises the following steps:

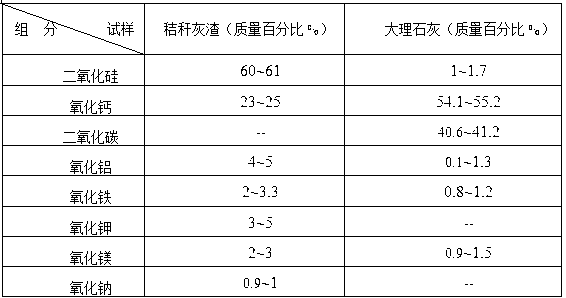

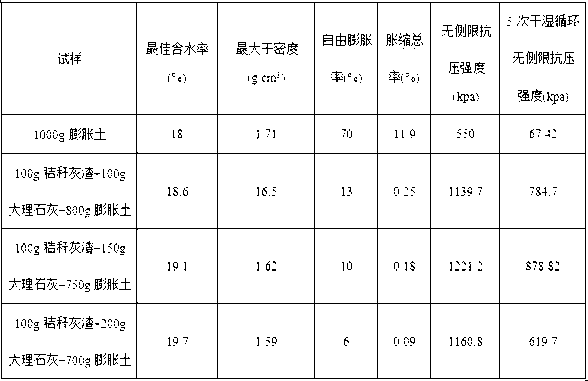

[0030] The first step is to prepare 1000g of mixed soil, according to the mass percentage of straw ash: marble ash: expansive soil (the dried soil sample is passed through a 0.5mm sieve) = 10:15:75, and the dry soil to be improved is weighed Quality 750g, straw ash 100g, marble ash 150g, mix uniformly; The analysis result of described straw ash is, in terms of the mass percentage of the oxide obtained after analysis and detection: silicon dioxide 61%, calcium oxide 25%, oxide Aluminum 5%, iron oxide 3%, potassium oxide 3%, magnesium oxide 2%, sodium oxide 1%; the analysis result of the marble ash is, based on the mass percentage of the oxide obtained after analysis and detection: calcium oxide 54.7% , carbon dioxide 40.9%, silicon dioxide 1%, aluminum oxide 1.3%, iron oxide 1.2%, magnesium oxide 0.9%.

[0031] In the second step, the optimal water conten...

Embodiment 2

[0037] The preparation method of expansive soil improved with waste straw ash and marble ash comprises the following steps:

[0038] The first step is to prepare 1000g of mixed soil, according to the mass percentage of straw ash: marble ash: expansive soil (the dried soil sample is passed through a 0.5mm sieve) = 10:20:70, and the dry soil to be improved is weighed Quality 700g, straw ash 100g, marble ash 200g, mix uniformly; The analysis result of described straw ash is, in terms of the mass percentage of the oxide obtained after analysis and detection: silicon dioxide 60%, calcium oxide 24.5%, oxide Aluminum 4.9%, iron oxide 2%, potassium oxide 4.8%, magnesium oxide 2.9%, sodium oxide 0.9%; the analysis result of the marble ash is, based on the mass percentage of the oxide obtained after analysis and detection: calcium oxide 55.2% , carbon dioxide 41.2%, silicon dioxide 1.2%, aluminum oxide 0.1%, iron oxide 0.8%, magnesium oxide 1.5%.

[0039] In the second step, the optima...

Embodiment 3

[0045] The preparation method of expansive soil improved with waste straw ash and marble ash comprises the following steps:

[0046] The first step is to prepare 1000g of mixed soil, according to the mass percentage of straw ash: marble ash: expansive soil (the dried soil sample is passed through a 0.5mm sieve) = 10:10:80, and the dry soil to be improved is weighed Quality 800g, straw ash 100g, marble ash 100g, mix uniformly; The analysis result of described straw ash is, in terms of the mass percentage of the oxide obtained after analysis and detection: silicon dioxide 60.7%, calcium oxide 23%, oxide Aluminum 4%, iron oxide 3.3%, potassium oxide 5%, magnesium oxide 3%, sodium oxide 1%; the analysis result of described marble ash is, in terms of the mass percent of the oxide obtained after analysis and detection: calcium oxide 54.1% , carbon dioxide 40.6%, silicon dioxide 1.7%, aluminum oxide 1.2%, iron oxide 1.2%, magnesium oxide 1.2%.

[0047] The second step is to determin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com