Process for treating excess sludge by utilizing fly ash

A technology of surplus sludge and process method, which is applied in the directions of dehydration/drying/concentrated sludge treatment, waste treatment, energy wastewater treatment, etc., and can solve problems such as environmental secondary pollution, affecting urban environmental sanitation, and occupying large land, and achieves The effect of large permeability coefficient, small cohesive force, and large internal friction angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

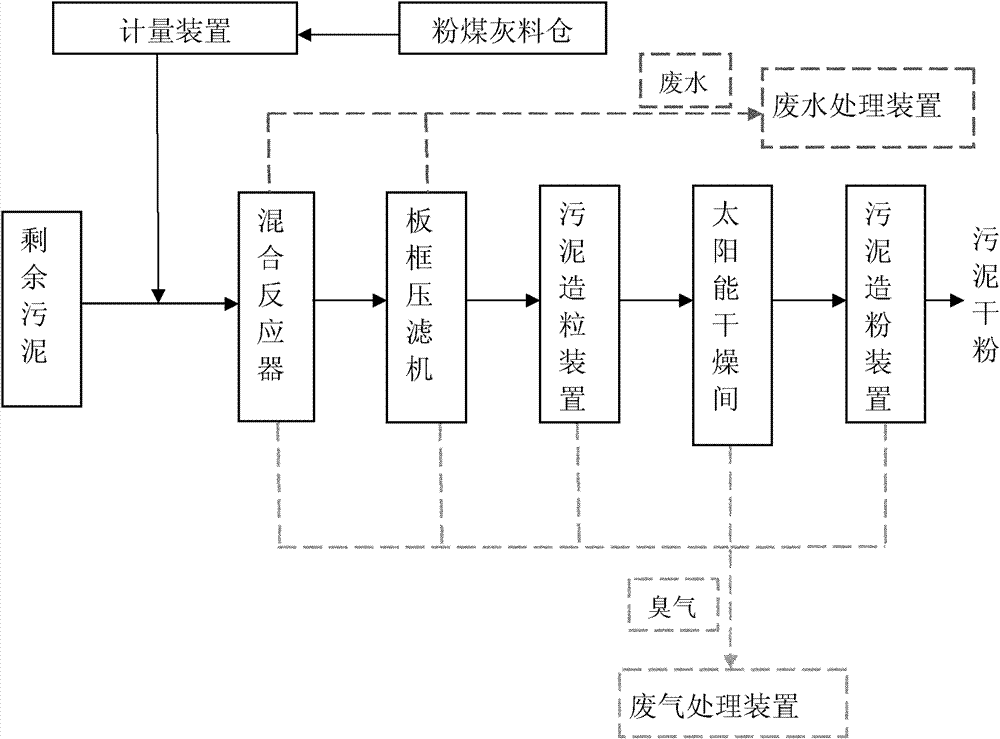

Image

Examples

Embodiment 1

[0020] The moisture content of excess sludge in a sewage treatment plant is 87.2%. According to the mass ratio of fly ash: excess sludge = 0.2:1, the fly ash and excess sludge are transported into the mixing reactor and fully mixed for 10 minutes. The mixed sludge is transported into the plate and frame filter press, and the hydraulic station provides the plate and frame filter press with a compacting pressure of 30MPa. The sludge particles are trapped in the filter chamber to form a semi-dried sludge cake, and the filtrate is collected by the collection device and returned to the sewage treatment system. The moisture content of the obtained semi-dried sludge cake was 40%.

[0021] The semi-dried sludge cake is transported into the sludge granulation device through the sludge cake conveyor, and the sludge granules with a larger specific surface area are produced, and the average particle size of the sludge granules is 3.7mm.

[0022] The outdoor temperature is 30°C during the...

Embodiment 2

[0025] The moisture content of excess sludge in a sewage treatment plant is 81.5%. According to the mass ratio of fly ash: excess sludge = 0.35:1, the fly ash and excess sludge are transported into the mixing reactor and fully mixed for 15 minutes. The mixed sludge is transported into the plate-and-frame filter press, and the hydraulic station provides a compacting pressure of 35MPa for the plate-and-frame filter press. The sludge particles are trapped in the filter chamber to form a semi-dried sludge cake, and the filtrate is collected by the collection device and returned to the sewage treatment system. The moisture content of the obtained semi-dried sludge cake was 38%.

[0026] The semi-dried sludge cake is transported into the sludge granulation device through the sludge cake conveyor, and the sludge granules with a larger specific surface area are produced, and the average particle size of the sludge granules is 3.3mm.

[0027] The outdoor temperature is 33°C during the...

Embodiment 3

[0030]The moisture content of the excess sludge in a sewage treatment plant is 90%. According to the mass ratio of fly ash: excess sludge = 0.5:1, the fly ash and excess sludge are transported into the mixing reactor and fully mixed for 5 minutes. The mixed sludge is transported into the plate-and-frame filter press, and the hydraulic station provides a compacting pressure of 35MPa for the plate-and-frame filter press. The sludge particles are trapped in the filter chamber to form a semi-dried sludge cake, and the filtrate is collected by the collection device and returned to the sewage treatment system. The moisture content of the obtained semi-dried sludge cake was 45%.

[0031] The semi-dried sludge cake is transported into the sludge granulation device through the sludge cake conveyor, and the sludge granules with a larger specific surface area are produced, and the average particle size of the sludge granules is 5mm.

[0032] The outdoor temperature is 33°C during the da...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com