Organic metal chemical vapor deposition device for high-temperature growth of oxide film

A technology of chemical vapor deposition and oxide thin film, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., which can solve the problem of uneven temperature distribution of substrate trays, erosion of furnace wire furnace electrodes, poor repeatability, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

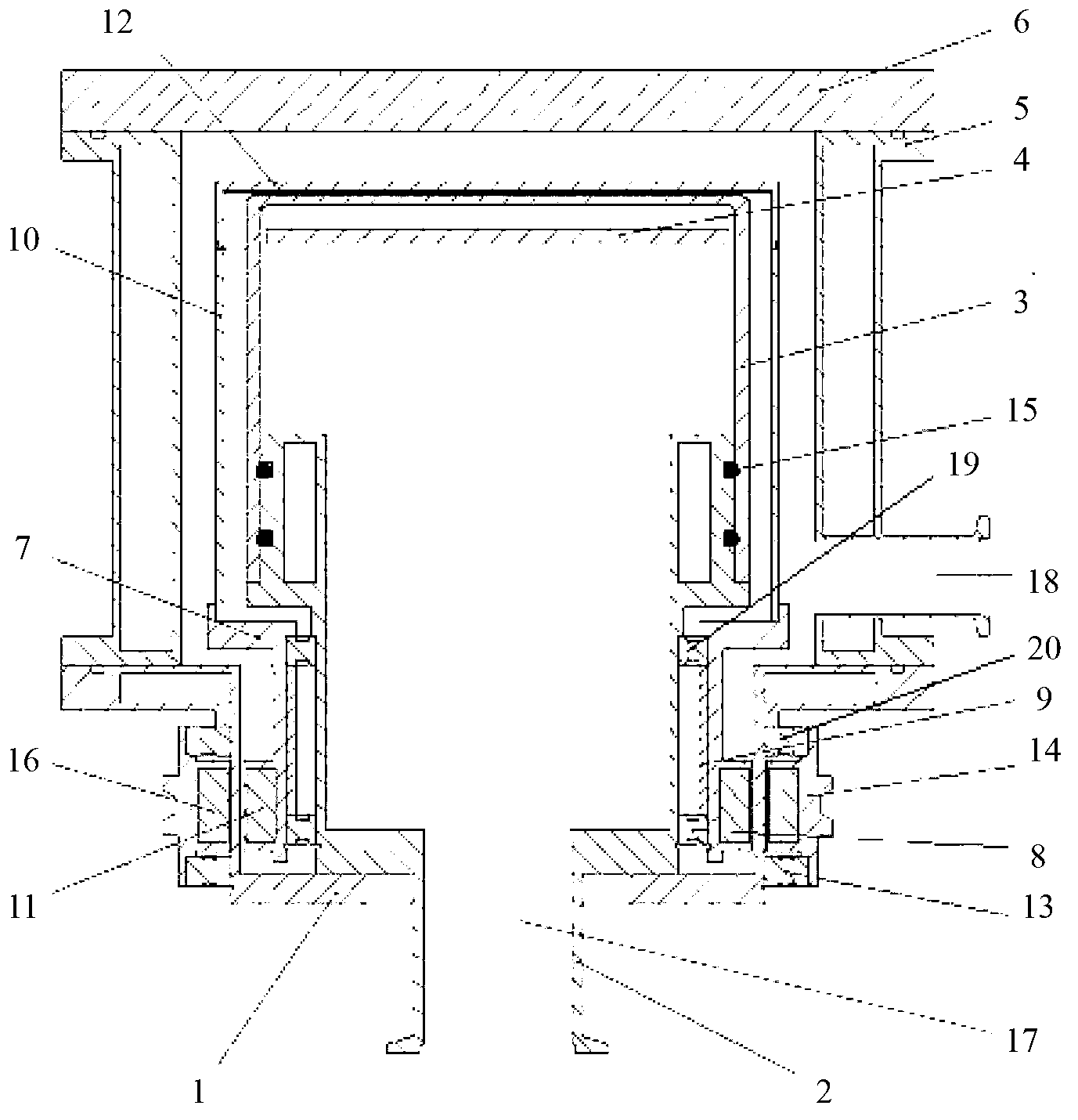

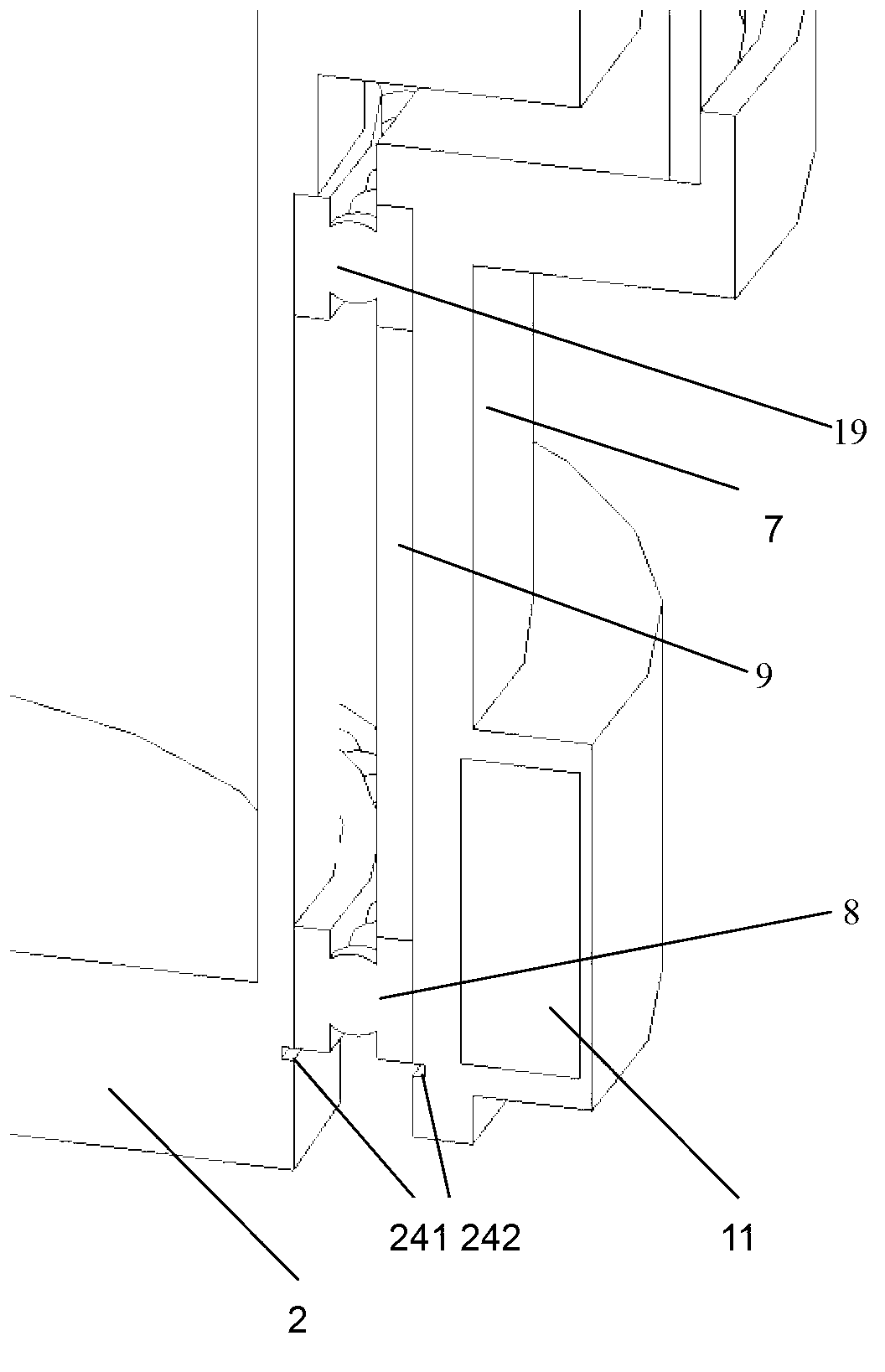

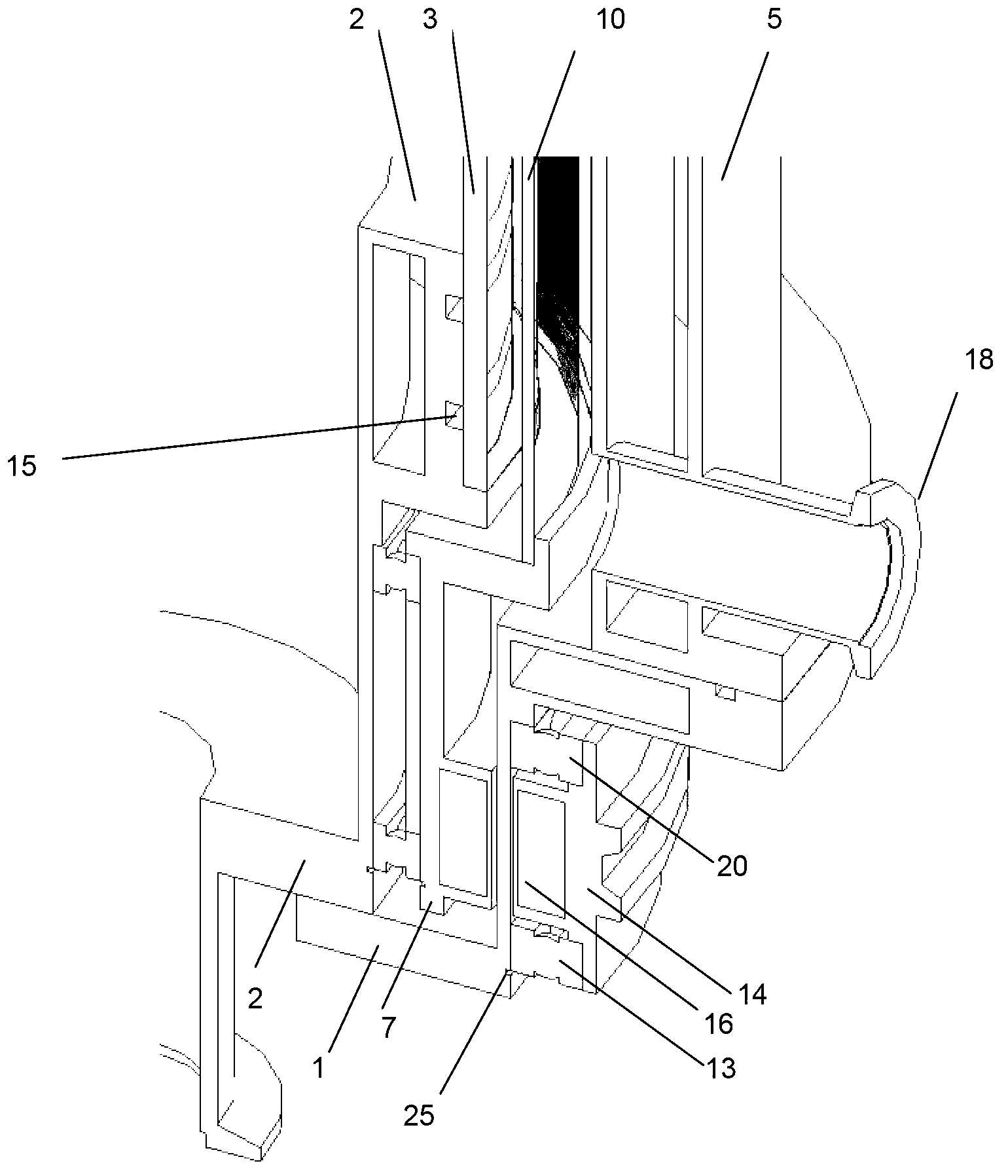

[0022] Such as figure 2As shown, the metal-organic chemical vapor deposition (MOCVD) system reaction chamber of the present invention consists of a water-cooled U-shaped flange base (1), a water-cooled torch-shaped hollow shaft (2), and a water-cooled reaction chamber side Wall (5), spray head (6) and vacuum system (18), with water-cooled U-shaped flange base (1), with water-cooled torch-shaped hollow shaft (2), with water-cooled reaction chamber side wall (5) and the spray head (6) are made of cylindrical stainless steel; the vacuum system (18) is connected to a mechanical pump and a molecular pump to ensure the vacuum degree of the reaction chamber; the spray head (6) and the side wall of the reaction chamber ( 5) The top of the reaction chamber is sealed with fast sampling locking technology (that is, one side is connected with a hinge, and the opposite side is locked with a screw), and the top of the reaction chamber side wall (5) is inlaid with an apron for vacuum sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com