Integrated device and method used for detecting COD (Chemical Oxygen Demand) and cleaning cuvette automatically

An integrated device, automatic detection technology, applied in the direction of using liquid cleaning methods, measuring devices, chemical instruments and methods, etc., can solve the problems of shortened cleaning detection time, unclean cleaning, poor COD measurement accuracy, etc., to provide work Efficiency, reduce the complexity of mechanical structure, reduce the effect of hardware cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

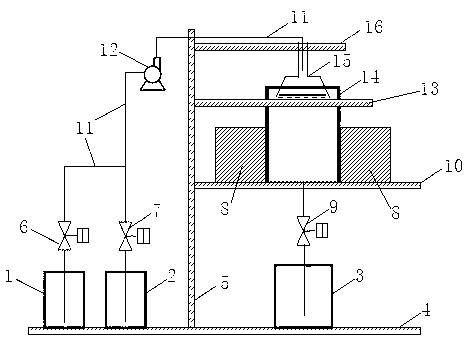

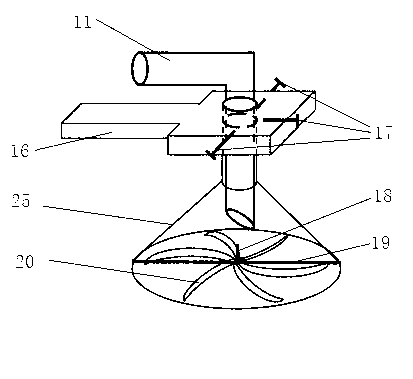

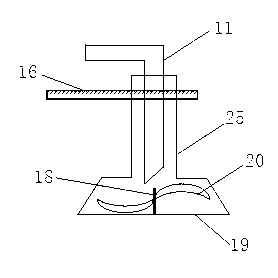

[0035] see Figure 1-8 As shown, the structure of the integrated device for automatically detecting COD and cleaning cuvettes of the present invention includes a distilled water bottle 1, a cleaning agent bottle 2, a waste liquid pool 3, a distilled water solenoid valve 6, a cleaning agent solenoid valve 7, and a waste liquid pool electromagnetic valve. Valve 9, automatic pump 12, ultrasonic cleaning device 8, water spray structure 15, photoelectric detection device 21, each support and single-chip microcomputer control system 22 (MCU control system).

[0036] see figure 1, the fixed floor support 4 is fixed horizontally, the bottom of the vertical support 5 is fixed on the fixed floor support 4, the middle of the vertical support 5 is fixedly connected to the cuvette fixed support 10, the cuvette fixed support 10 is fixed horizontally, and the cuvette 14 is placed On the horizontal cuvette fixing support 10 , and the cuvette 14 is also fixed on the vertical support 5 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com