Compound type carbon dioxide adsorbent

A carbon dioxide and adsorbent technology, which is applied in the field of composite carbon dioxide adsorbents, can solve the problems of reduced adsorption stability of organic matter and silicon dioxide, influence on adsorption effect, and decreased adsorption performance, and achieve simple preparation methods, high adsorption selectivity, The effect of easy desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

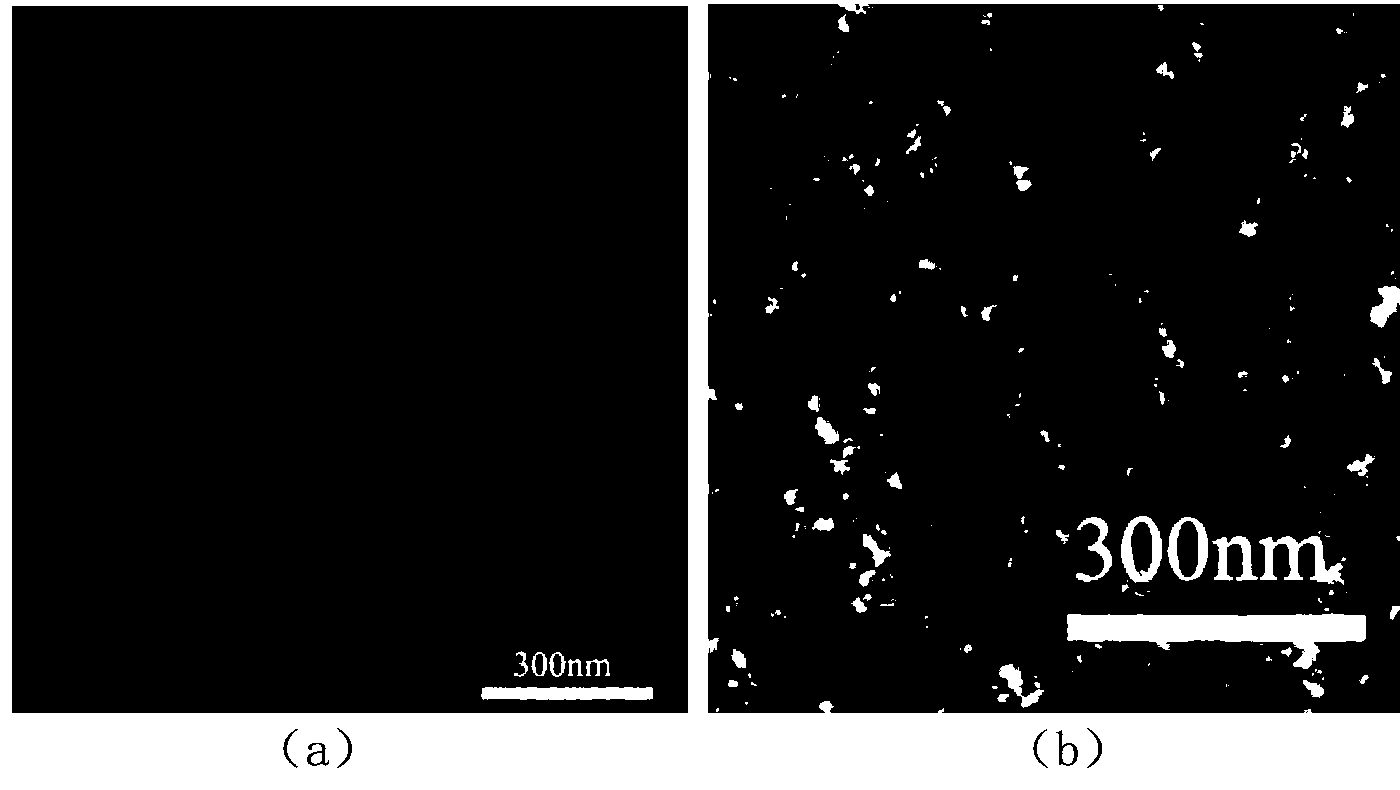

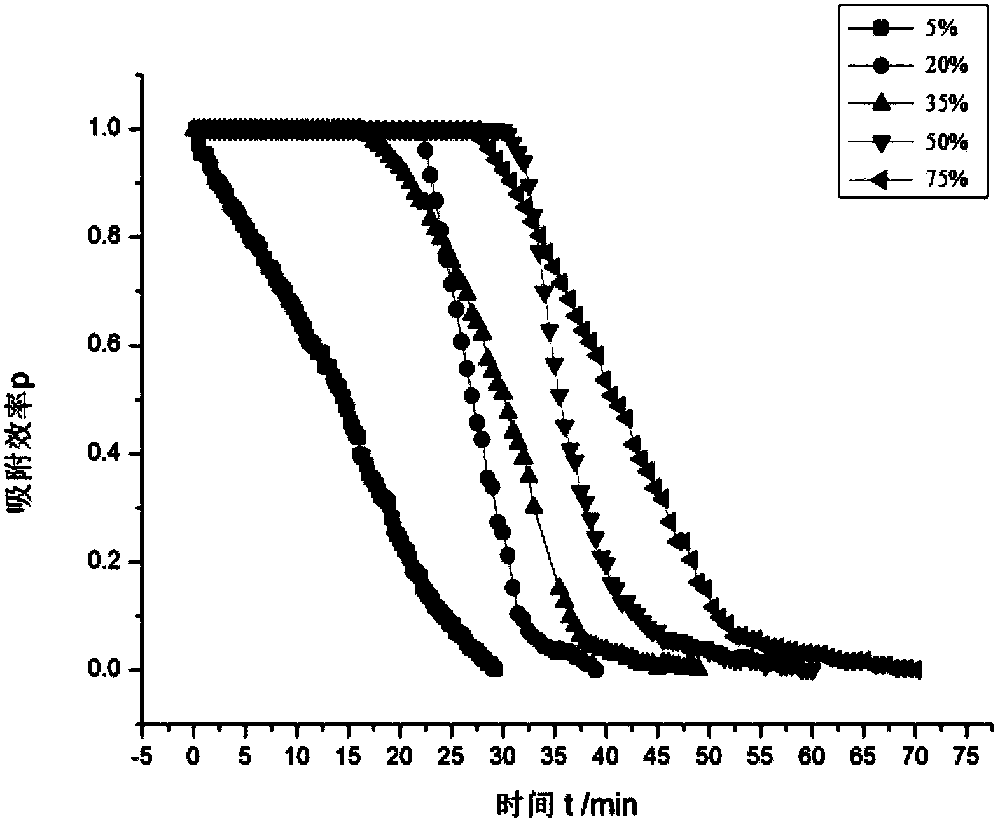

[0032] The composite carbon dioxide adsorbent of this embodiment includes silica mesoporous particles, water, and polyethylene polyamine adsorbed in the pores and surfaces of the mesoporous particles. The molecular structure of the polyethylene polyamine is as follows: ) Shows:

[0033] (I), where x=1 and y=9.

[0034] The preparation method is as follows:

[0035] Step 1: Hydrolyze the silica precursor (methyl orthosilicate) to form silica gel;

[0036] Step 2: Add phosphoric acid with a concentration of 60% by mass to the silica gel, quickly stir for 2 minutes and perform high-temperature gelation for 16 hours at a gel temperature of 75°C to obtain a mixture of silica mesoporous particles and phosphoric acid ; Among them, the molar ratio of phosphoric acid to methyl orthosilicate is 1;

[0037] Step 3: Wash off the phosphoric acid in the mixture of mesoporous silica particles and phosphoric acid with water, and dry the mesoporous silica particles to obtain the silica mesoporous par...

Embodiment 2

[0041] The composite carbon dioxide adsorbent of this embodiment includes silica mesoporous particles, water, and polyethylene polyamine adsorbed in the pores and surfaces of the mesoporous particles. The molecular structure of the polyethylene polyamine is as follows: ) Shows:

[0042] (I), where x=9091 and y=909.

[0043] The preparation method is as follows:

[0044] Step one: hydrolyze the silica precursor (ethyl orthosilicate) to form silica gel;

[0045] Step 2: Add phosphoric acid with a concentration of 30% by mass to the silica gel, quickly stir for 2 minutes and then perform high-temperature gelation for 24 hours at a gel temperature of 90°C to obtain a mixture of mesoporous silica particles and phosphoric acid ; Among them, the molar ratio of phosphoric acid to ethyl orthosilicate is 2;

[0046] Step three, washing off the phosphoric acid in the mixture of mesoporous silica particles and phosphoric acid with water, and drying to obtain mesoporous silica particles;

[0047] ...

Embodiment 3

[0050] The composite carbon dioxide adsorbent of this embodiment includes silica mesoporous particles, water, and polyethylene polyamine adsorbed in the pores and surfaces of the mesoporous particles. The molecular structure of the polyethylene polyamine is as follows: ) Shows:

[0051] (I), where x=500 and y=500.

[0052] The preparation method is as follows:

[0053] Step one: hydrolyze the silica precursor (methyltrimethoxysilane) to form a silica gel;

[0054] Step 2: Add phosphoric acid with a concentration of 90% by mass to the silica gel, quickly stir for 2 minutes and then perform high-temperature gelation for 8 hours at a gel temperature of 50°C to obtain a mixture of mesoporous silica particles and phosphoric acid ; Wherein, the molar ratio of phosphoric acid to methyl trimethoxysilane is 0.1;

[0055] Step three, washing off the phosphoric acid in the mixture of mesoporous silica particles and phosphoric acid with water, and drying to obtain mesoporous silica particles;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com