Process for producing LED lamp and corresponding LED lamp

A technology of LED lamps and manufacturing methods, applied in the direction of lighting and heating equipment, components of lighting devices, and damage prevention measures for lighting devices, etc., can solve problems such as high consumption, high cost, and adhesives that cannot be dried, and achieve Effective force transmission, chip avoidance and tightening process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

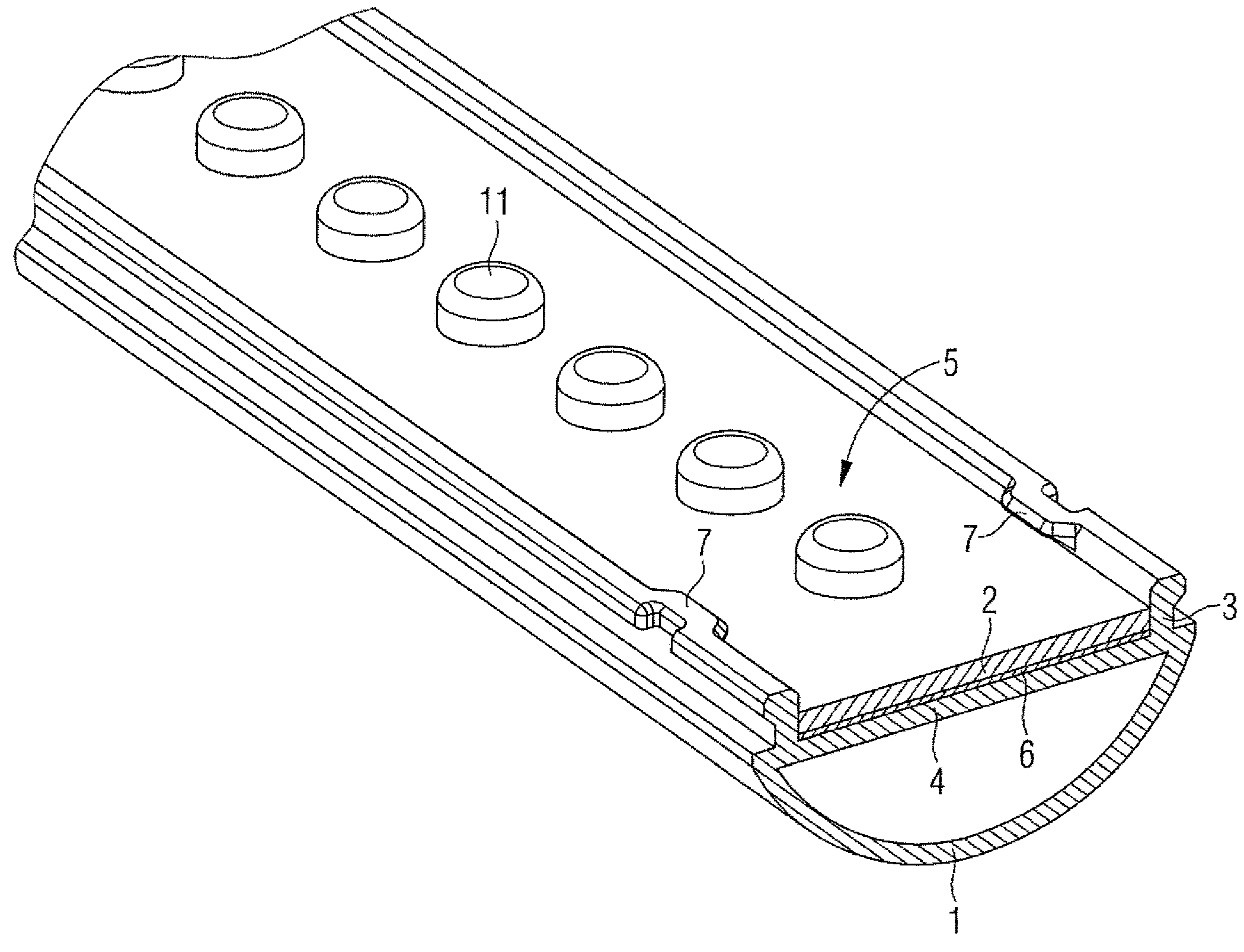

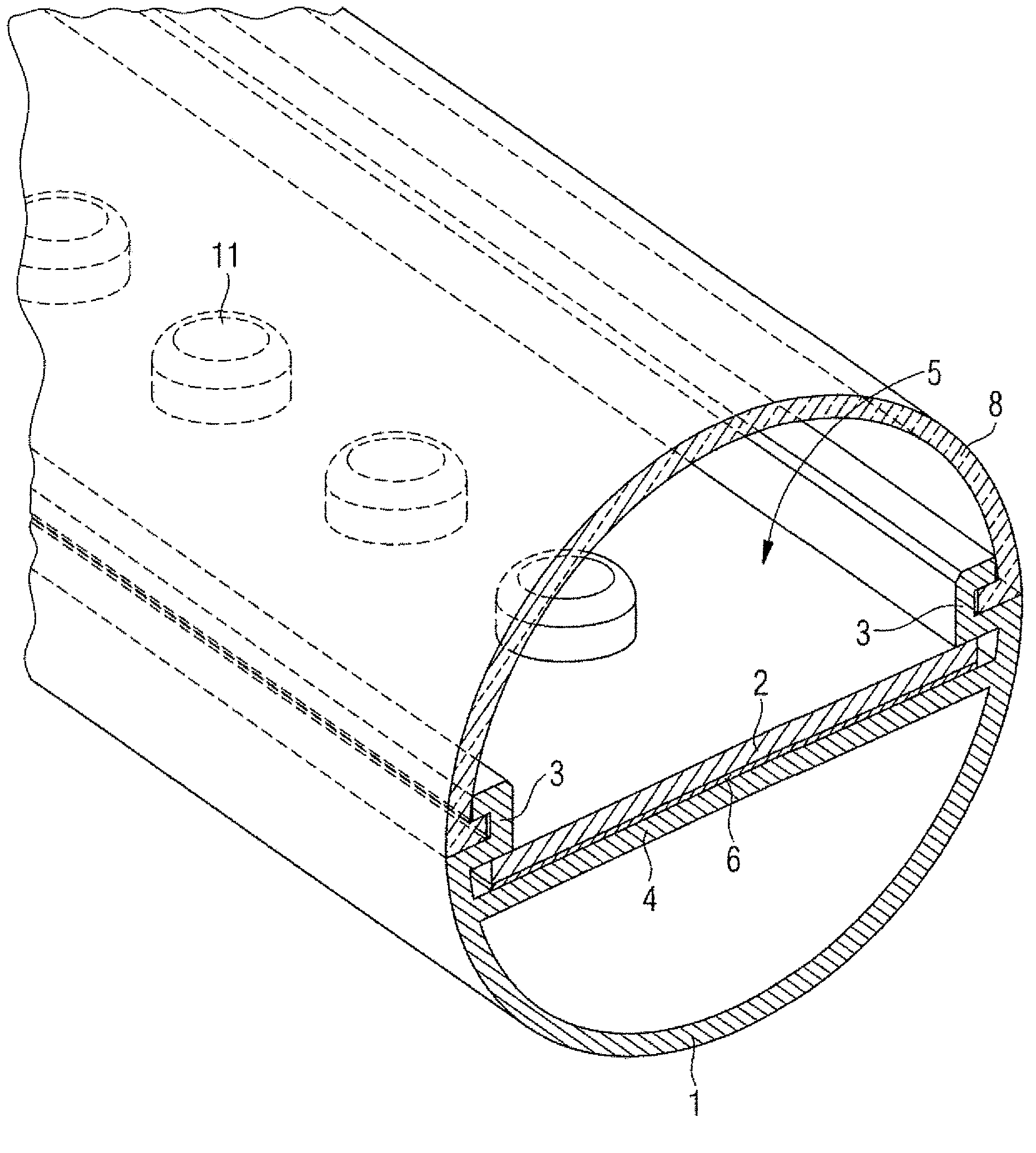

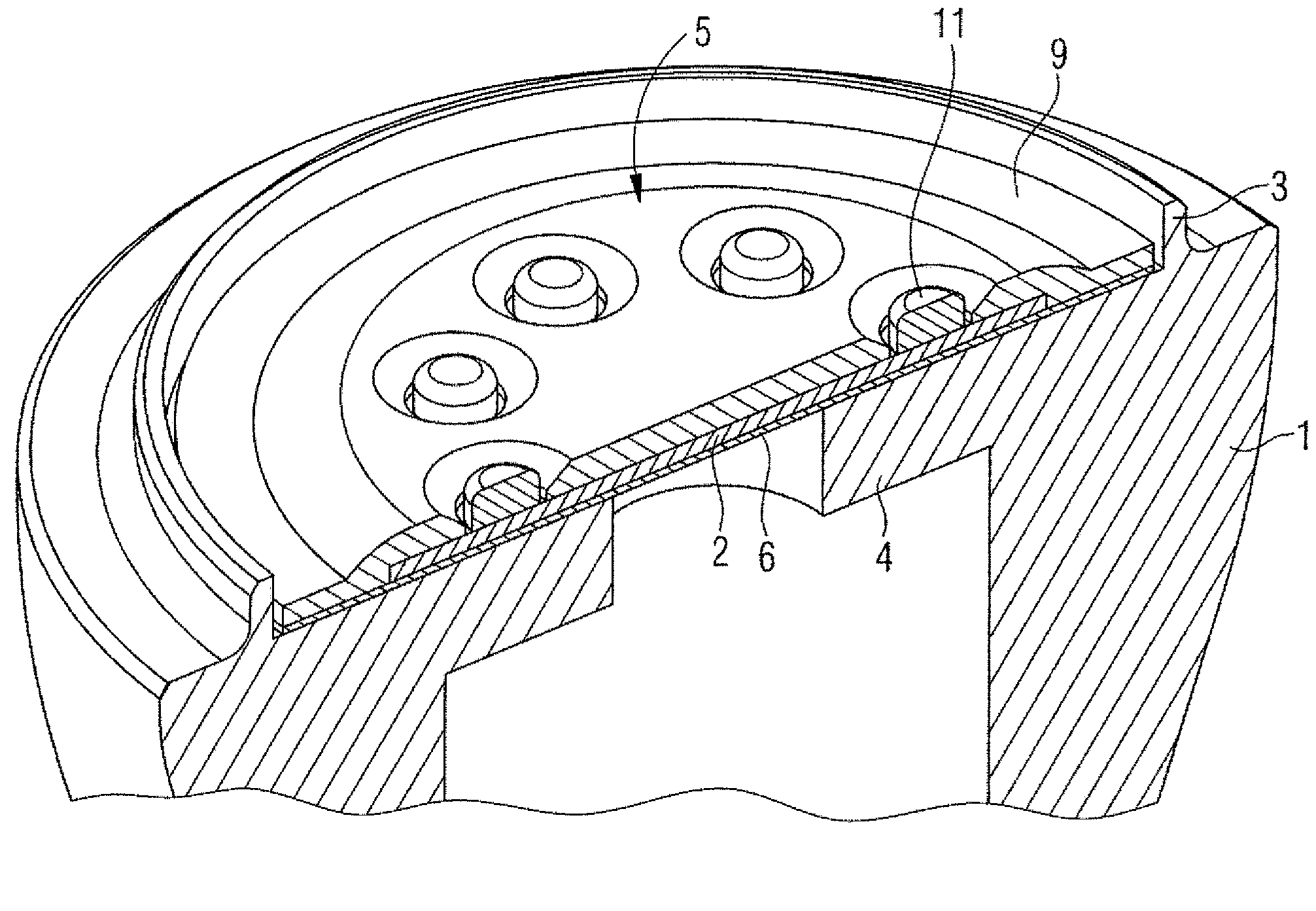

[0026] figure 1 The manufacturing method according to the invention or a first embodiment of an LED lamp (retrofit lamp tube) manufactured according to the invention is shown in a perspective view. exist figure 1 The LED lamp shown in has an approximately semi-cylindrical lamp housing 1 with a central web 4 . All other shapes of lamp housing 1 and carrier circuit board 2 are also conceivable, since they mostly depend on the specific purpose of use. Protruding parts 3 are respectively designed on the left side and the right side of the lamp housing 1 . The carrier circuit board 2 in the lamp housing 1 is arranged between the projections 3 , an insulating layer 6 being introduced between the carrier circuit board 2 and the lamp housing 1 or the central web 4 . In this case, the projection 3 and the central web 4 form a so-called carrier circuit board base 5 , in which the carrier circuit board 2 is arranged. In this case, the carrier circuit board base 5 can be designed in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com