Combined cycle power plant with CO2 capture and method to operate it

A technology of power equipment and combined cycle, applied in the direction of mechanical equipment, combined combustion mitigation, machine/engine, etc., can solve the problems of absorption solution deterioration, CO2 capture equipment efficiency increase, CO2 capture equipment operation and maintenance cost increase, etc. Achieve increased flexibility, improved performance and profitability, and increased efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

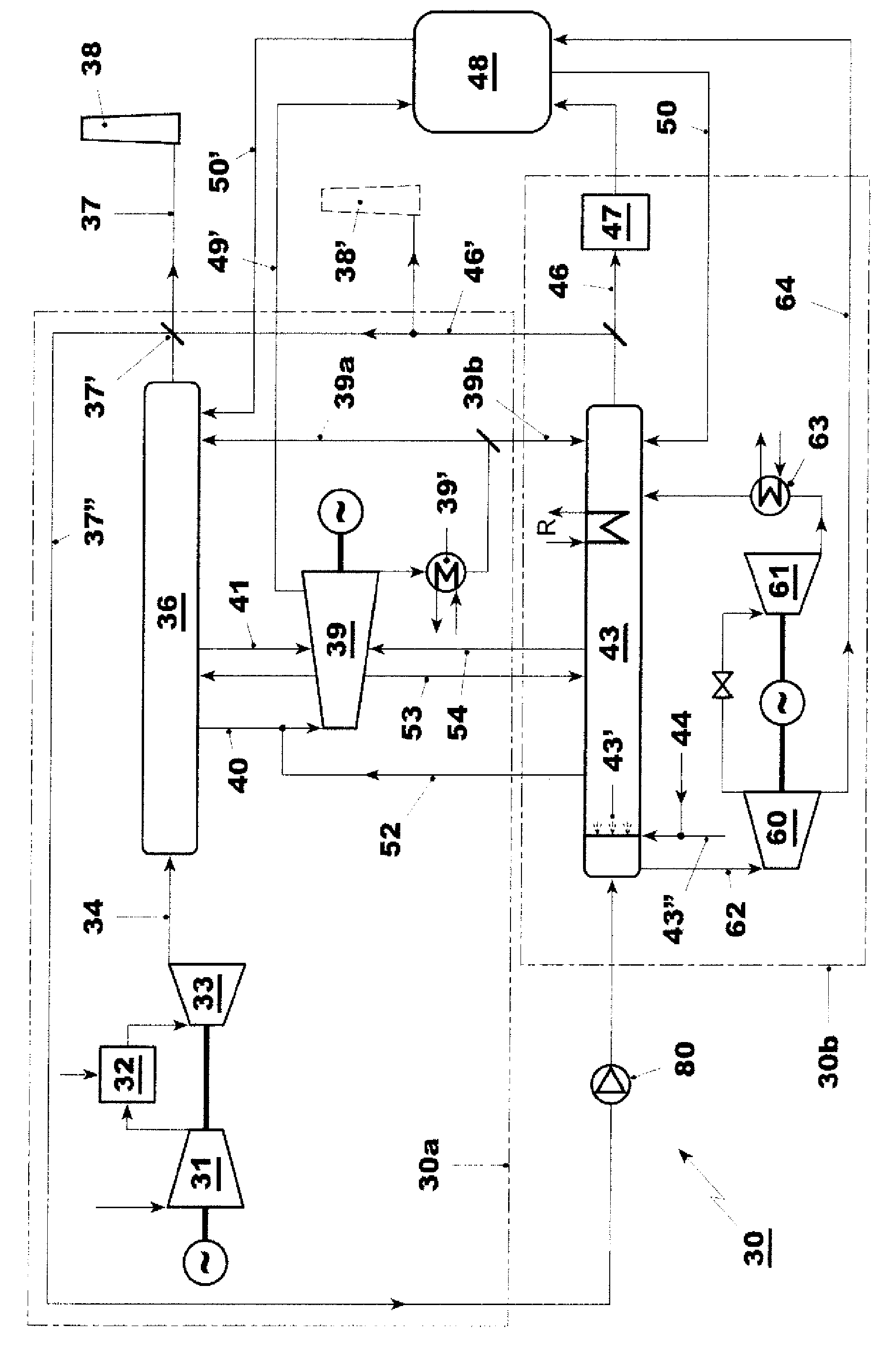

[0048] The power plant 30 for generating electric power according to the present invention as shown in FIGS. A combined cycle power plant with a gas turbine 33 driving an electric generator. Exhaust lines 34 , 35 lead exhaust gas from the gas turbine to a first HRSG 36 where it is used for steam generation and then through an exhaust gas line 37 which leads the exhaust gas to a stack 38 .

[0049] The steam generated in the first HRSG is passed via live steam line 40 to a steam turbine 39 which in turn drives another generator. The steam discharged by the steam turbine 39 is passed into the condenser 39', and the resulting condensate is introduced into the HRSG 36 via line 39a for steam generation, thereby completing the water steam cycle.

[0050] The unit 30b of the power plant 30 mainly comprises a second HRSG 43 operating with the hot exhaust gas from the unit 30a branched from the exhaust line 34 by means of a baffle or flow divider 34'. The exhaust is used for hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com