A pipe welding rod with low stress wear resistance

A low-stress, welding rod technology, applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc., to achieve good welding processability, improved pressure bearing capacity and impact resistance, and good welding processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

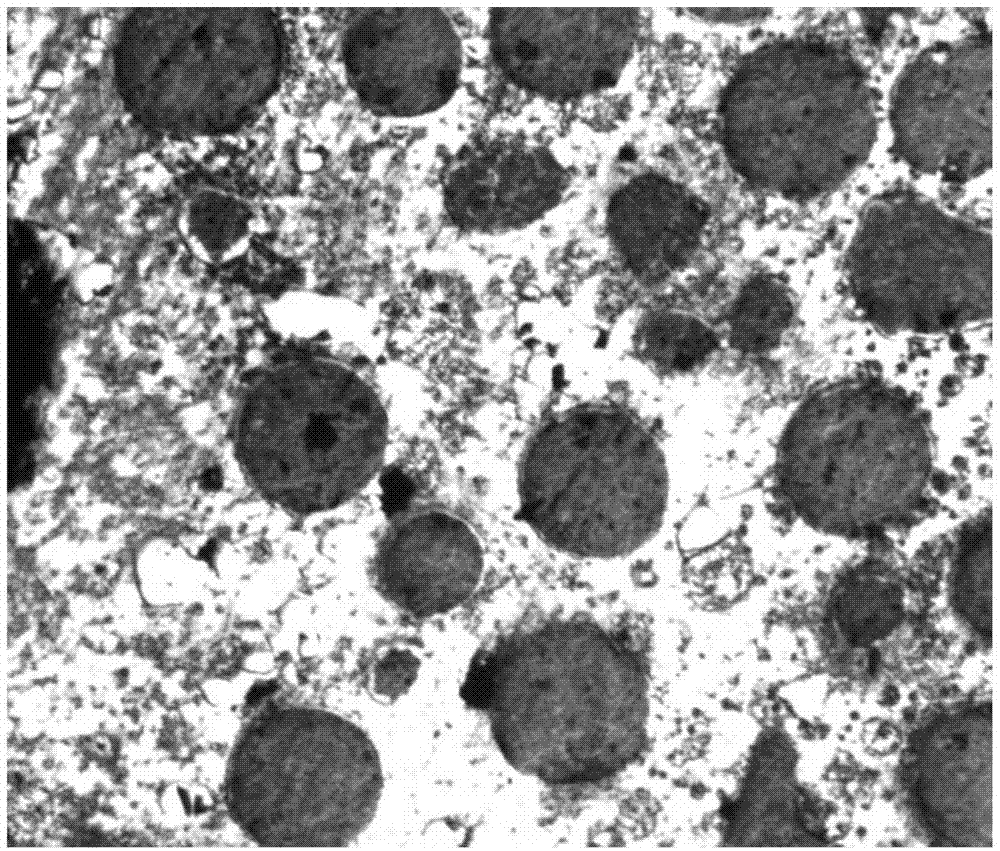

Image

Examples

Embodiment 1

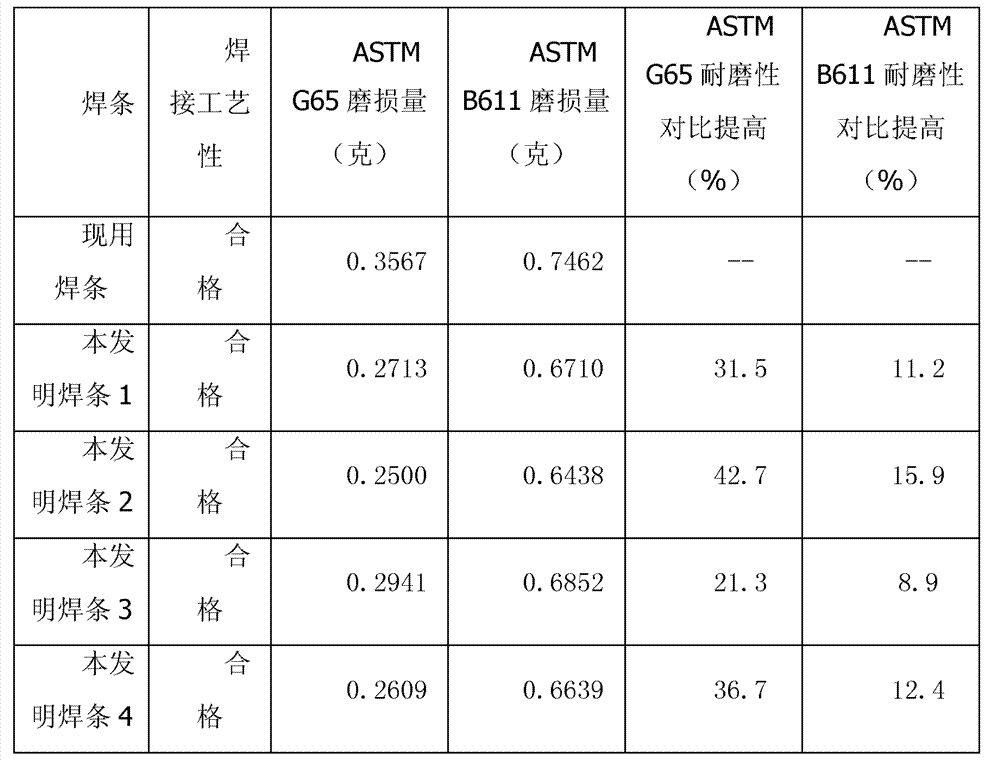

[0020] Embodiment 1: design and manufacture a kind of pipe welding rod according to the technical scheme of the present invention, the filler of pipe welding rod is by the casting tungsten carbide particle of 15% macrocrystalline tungsten carbide particle, 65% surface carburizing treatment, 15% by weight percentage. % spherical cast tungsten carbide particles, 4% alloy powder and 1% organic binder, among which, the particle size of macrocrystalline tungsten carbide particles is 60-100 mesh, and the particle size of cast tungsten carbide particles after carburizing treatment is 80-140 mesh The particle size of spherical cast tungsten carbide particles is 80-200 mesh, and the above particle sizes are all sieved according to the American standard. The weight percentage of each component of the alloy powder in the alloy powder is 18% iron, 12% silicon, 48% manganese, 11% niobium, Nickel is 11%, and the percentage by weight of the filler in the tube electrode is 65%. The welded pip...

Embodiment 2

[0021] Embodiment 2: Design and manufacture a kind of pipe welding rod according to the technical scheme of the present invention, the filler in the pipe welding rod welded pipe is by weight percent the casting tungsten carbide particle of 15% macrocrystalline tungsten carbide particle, 15% surface carburizing treatment , 64% spherical cast tungsten carbide particles, 5% alloy powder and 1% organic binder, among which, the particle size of macrocrystalline tungsten carbide particles is 20-100 mesh, and the particle size of cast tungsten carbide particles after carburizing treatment is 40 ~100 mesh, spherical casting tungsten carbide particle size is 80 ~ 200 mesh, the above particle size is sieved according to the American standard, the weight percentage of each component of the alloy powder is iron 15%, silicon 15%, manganese 50%, niobium 10 %, nickel 10%, and the percentage by weight of the filler in the tube electrode is 73%. The welded pipe is rolled from a low-carbon stee...

Embodiment 3

[0022] Embodiment 3: design and manufacture a kind of pipe welding rod according to the technical scheme of the present invention, the filler of pipe welding rod is by the casting tungsten carbide particle of 45% macrocrystalline tungsten carbide particle, 25% surface carburizing treatment, 5% by weight percentage. % spherical cast tungsten carbide particles, 20% mechanically crushed cast tungsten carbide particles, 4% alloy powder and 1% organic binder, among which, the particle size of macrocrystalline tungsten carbide particles is 60-140 mesh, and the surface is carburized The particle size of cast tungsten carbide treated is 80-200 mesh, the particle size of spherical cast tungsten carbide particle is 40-100 mesh, and the particle size of mechanically crushed cast tungsten carbide particle is 40-100 mesh. The weight percentage of the components in the alloy powder is 18% of iron, 12% of silicon, 48% of manganese, 11% of niobium and 11% of nickel, and the weight percentage o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com