Filler-textured polymer matrix composite material with high thermal conductivity and preparation method thereof

A technology of composite materials and polymers, applied in the field of high thermal conductivity polymer-based composite materials and their preparation, can solve the problems of low thermal conductivity, achieve excellent thermal conductivity, simple and easy method, and increase the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

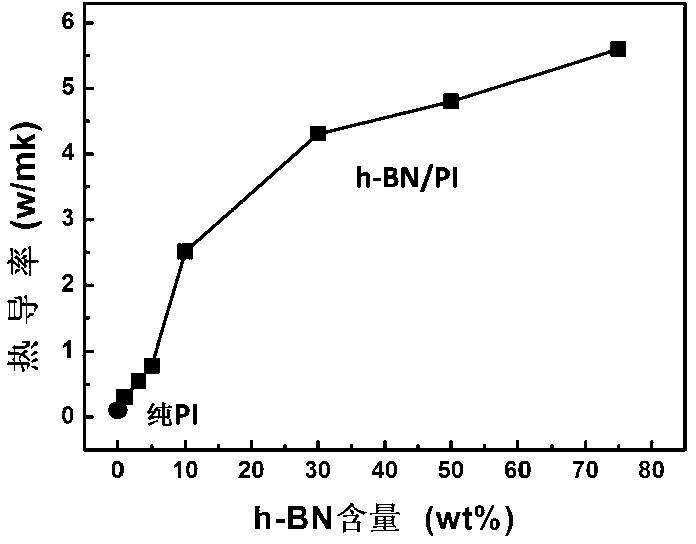

[0024] The preparation method of the filler-textured high thermal conductivity polymer-based composite material of the present invention includes: uniformly dispersing micro-nano inorganic powders with two-dimensional geometry in a thermoplastic resin polymer solution, or making the inorganic filler A mixing process in which the powder is uniformly dispersed in the prepolymer / monomer capable of synthesizing the polymer by in-situ polymerization to form a mixture slurry; and a molding method capable of providing directional force to texture the filler A molding process of molding the mixture slurry. The material of the invention uses an organic polymer as a matrix and an inorganic substance as a filler, has high thermal conductivity, and has good processability and flexibility. Among them, the polymers used are most common thermoplastic resins or polymers that can be synthesized by in-situ polymerization. Inorganic fillers are hexagonal boron nitride, graphite, graphite oxide,...

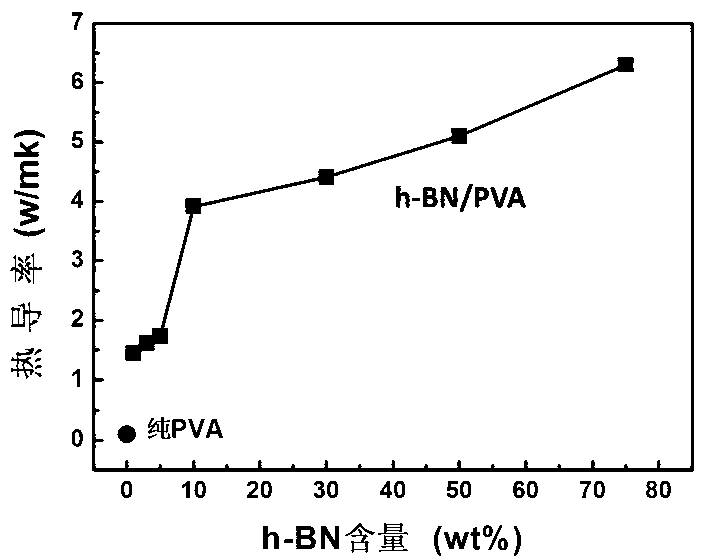

Embodiment 1

[0044] To prepare 3wt% h-BN / polyvinyl alcohol composite material, 0.12g h-BN was mixed with 4g polyvinyl alcohol particles, then 36g water was added, and the mixture was stirred at a constant temperature of 90°C for 300min. After the polyvinyl alcohol is completely dissolved and mixed evenly with h-BN, the viscous mixture is poured on the casting plate for casting, and the casting speed is adjusted to 0.8m / min, and the thickness is 0.4mm. After casting, let it dry naturally for 24 hours and demould. The thermal conductivity of the obtained composite material in the direction parallel to the casting direction is as high as 1.61W / (m k) (LFA447 thermal conductivity meter from NETZSCH Company), which is 16 times higher than that of pure polyvinyl alcohol, and the obtained sample is flexible Excellent sex.

Embodiment 2

[0046] To prepare 10wt% h-BN / polyvinyl alcohol composite material, 0.36g h-BN was mixed with 3.2g polyvinyl alcohol particles, then 36.8g water was added, and the mixture was stirred at a constant temperature of 90°C for 300min. After the polyvinyl alcohol is completely dissolved and mixed evenly with h-BN, the viscous mixture is poured on the casting plate for casting, and the casting speed is adjusted to 0.8m / min, and the thickness is 0.4mm. After casting, let it dry naturally for 24 hours and demould. The thermal conductivity of the obtained composite material in the direction parallel to the casting direction is as high as 3.92W / (m k) (LFA447 thermal conductivity meter from NETZSCH Company), which is 39 times higher than that of pure polyvinyl alcohol, and the obtained sample is flexible Excellent sex.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com