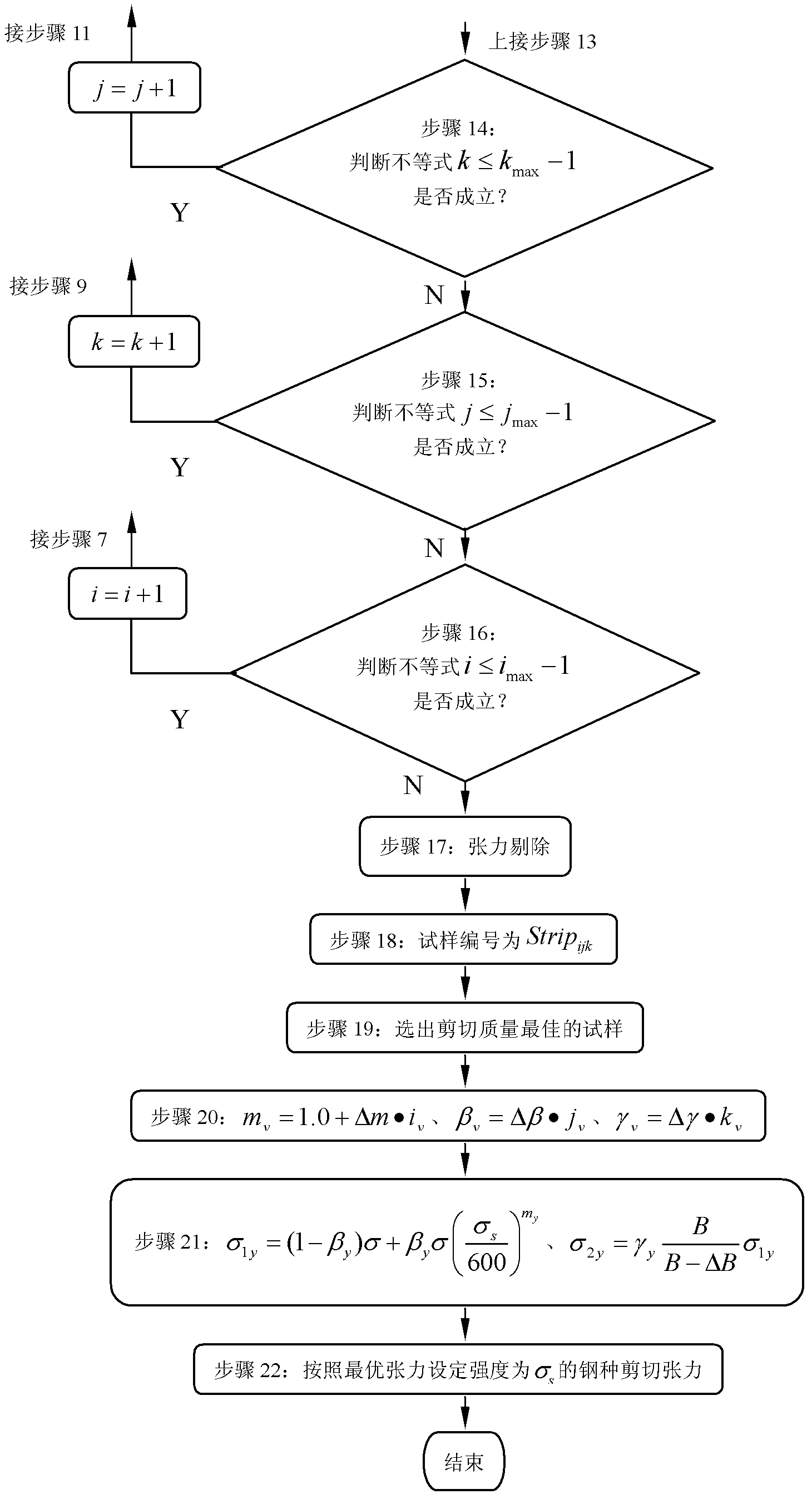

Comprehensive optimization setting method for front and back reference tension of disk shear of PL-TCM (pickling line tandem cold rolling mill)

An optimized setting, disc shearing technology, used in shearing machine equipment, shearing devices, metal processing equipment, etc., can solve the problems of unstable shearing process and poor tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0089] In order to further illustrate the application process of the related technical solutions described in the present invention, now taking a strip with a tapping mark of AP0961E1 and a yield strength of 260Mpa as an example, the process of setting the reference tension before and after a certain 1420 acid rolling disc shear is introduced in detail:

[0090] First, collect the shearing process parameters of the disc shears, mainly including the initial reference tension of the disc shears σ=19.2Mpa, and the amount of the disc shearing edge ΔB=20mm;

[0091] In the second step, the main characteristic parameters of the strip to be sheared are collected, including the strength σ of the strip s =260Mpa, strip width B, the specific values are shown in Table 1;

[0092] The third step is to determine the minimum value m of the tension decay index min =1.0, the maximum value of the tension attenuation index is 1.0, and the minimum value of the steel type influence coefficient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com