Non-heat-treated steel for soft nitriding, and soft-itrided component

A technology of nitrocarburized parts and non-quenched and tempered steel, which is applied in the fields of non-quenched and tempered steel for nitrocarburized parts and steel for nitrocarburized parts, to achieve excellent bending correction, high bending fatigue strength, and easy manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0110] Steels A to N having the chemical compositions shown in Table 3 were smelted in a 70-ton converter, and rolled into billets with a cross-sectional size of 180mm×180mm.

[0111] Steels A to E in Table 3 are steels whose chemical compositions are within the range specified by the present invention. On the other hand, steels F to N are steels whose chemical compositions do not satisfy the conditions specified in the present invention.

[0112] [table 3]

[0113]

[0114] The above-mentioned steel was forged into a steel bar with a diameter of 90 mm, and further forged into a steel bar with a diameter of 50 mm under conditions of a heating temperature of 1200° C. and a finishing temperature of 1000 to 1050° C. After forging, it is naturally cooled to room temperature in the atmosphere.

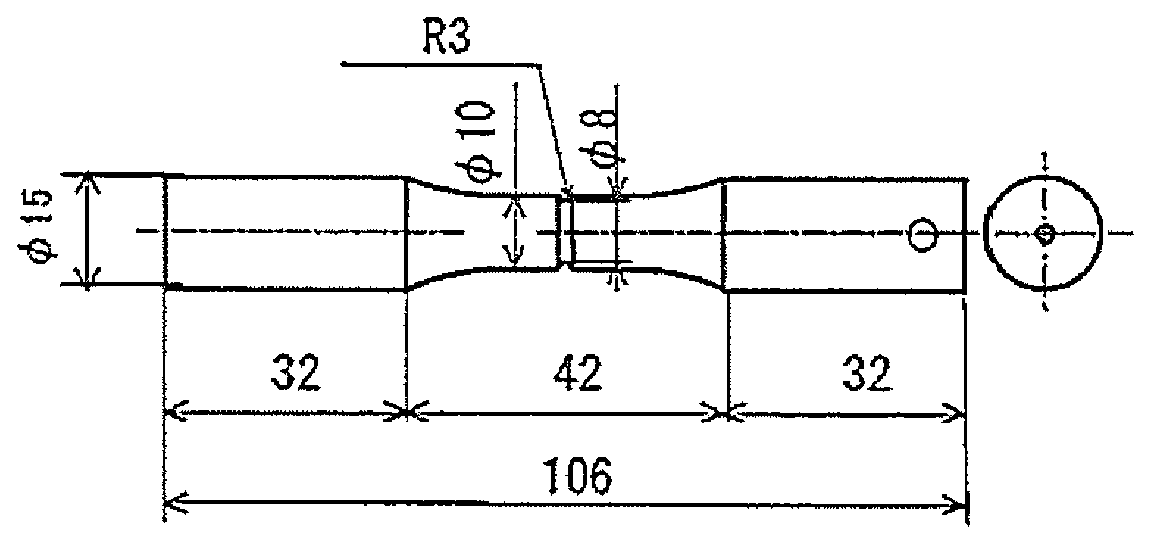

[0115] Selected from the R / 2 portion of each steel bar with a diameter of 50mm obtained as described above figure 1 Ono-type rotating bending fatigue test piece with the shape shown ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending fatigue strength | aaaaa | aaaaa |

| bending fatigue strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com