Multifunctional fixture for drilling rigs

A multi-functional, fixture technology, applied in drill pipe, drill pipe, drilling equipment, etc., can solve the problems of inability to hold the drill pipe, easy damage of parts, improve work quality and efficiency, reduce damage to parts, The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

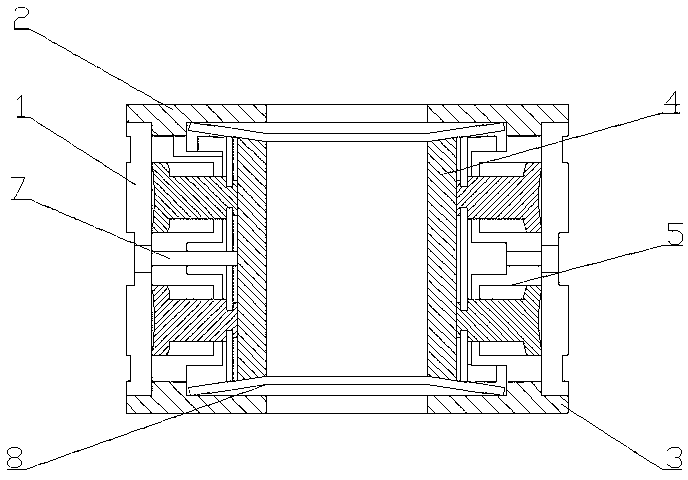

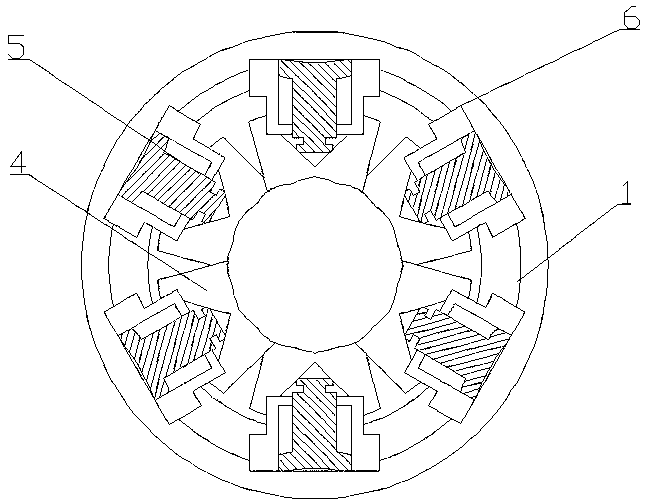

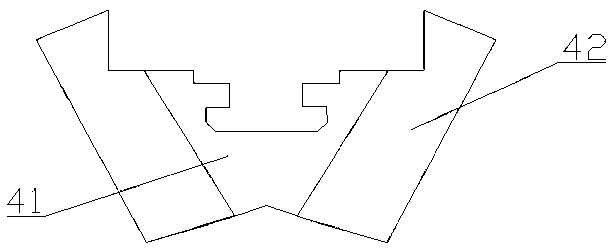

[0023] As shown in the figure: a multifunctional fixture for a drilling rig, including a cylindrical shell 1, a front end cover 2 and a rear end cover 3, the shell 1 is arranged between the front end cover 2 and the rear end cover 3, the front end Both the cover 2 and the rear end cover 3 have a central through hole. The multi-functional fixture also includes slips 4 and hydraulic cylinder 5, and the inner wall of the housing 1 is evenly provided with at least two oil cylinder slots 6 along the circumference, and the oil cylinder slots 6 are arranged axially, and the oil cylinders are embedded in the slots 6. In the positioning and fastening of the hydraulic cylinder 5. A plurality of oil passages are made along the circumference of the housing 1 and in the axial and radial directions. One end of the axial oil passage communicates with the annular oil passage, and the other end communicates with the radial oil passage of the rear end cover 3, so that the oil from the power out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com