Eccentric shaft of pavement roller vibration generator

A vibration device and eccentric shaft technology, applied in the field of eccentric shafts, can solve the problems of large load, large loss of power part, large torque, etc., and achieve the effect of reducing vibration and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

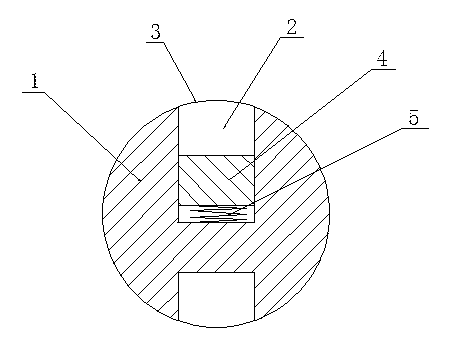

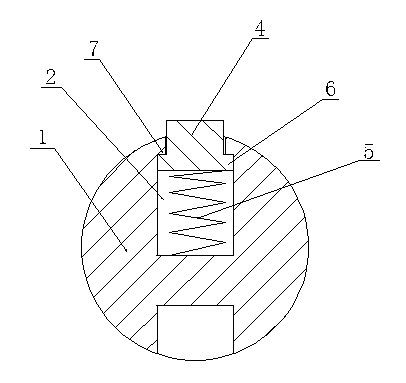

[0010] The embodiments of the present invention will be described in detail in conjunction with the accompanying drawings.

[0011] An eccentric shaft of a vibrating device for a road roller. The shaft body 1 of the eccentric shaft is cylindrical, and a chute 2 parallel to the axial direction is provided inside the shaft body 1. The notch 3 of the chute 2 is located at the bottom of the shaft body 1 On one side of the peripheral surface, an eccentric slider 4 is arranged in the chute 2, and the eccentric slider 4 slides along the chute toward the notch 3 under centrifugal action. The bottom end of the eccentric slider 4 is connected to the bottom of the chute 2 through the tension spring 5. When the tension spring 5 is in the reset state, the center of gravity of the eccentric shaft formed by the eccentric slider 4 and the shaft body 1 is located on the axis of the shaft body 1. . Therefore, in the state where the eccentric shaft stops, its center of gravity does not deviate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com