Polypropylene composite material for automobile internal ornament, preparation method thereof and internal ornament

A composite material and automotive interior technology, which is applied in the field of interior parts, polypropylene composite materials and their preparation, can solve problems such as difficult to wipe clean dust, and achieve excellent mechanical properties, improved performance, and excellent surface scratch resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

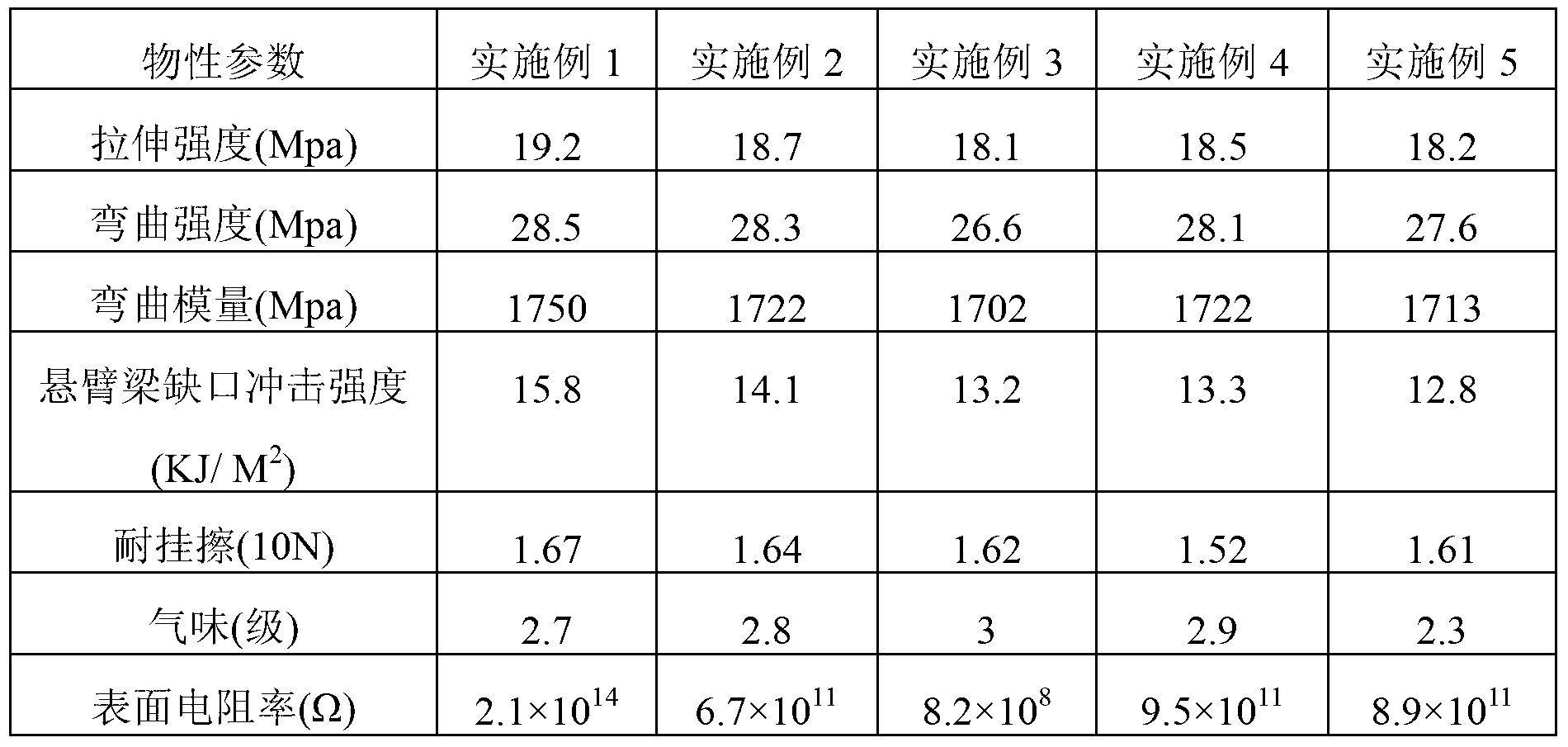

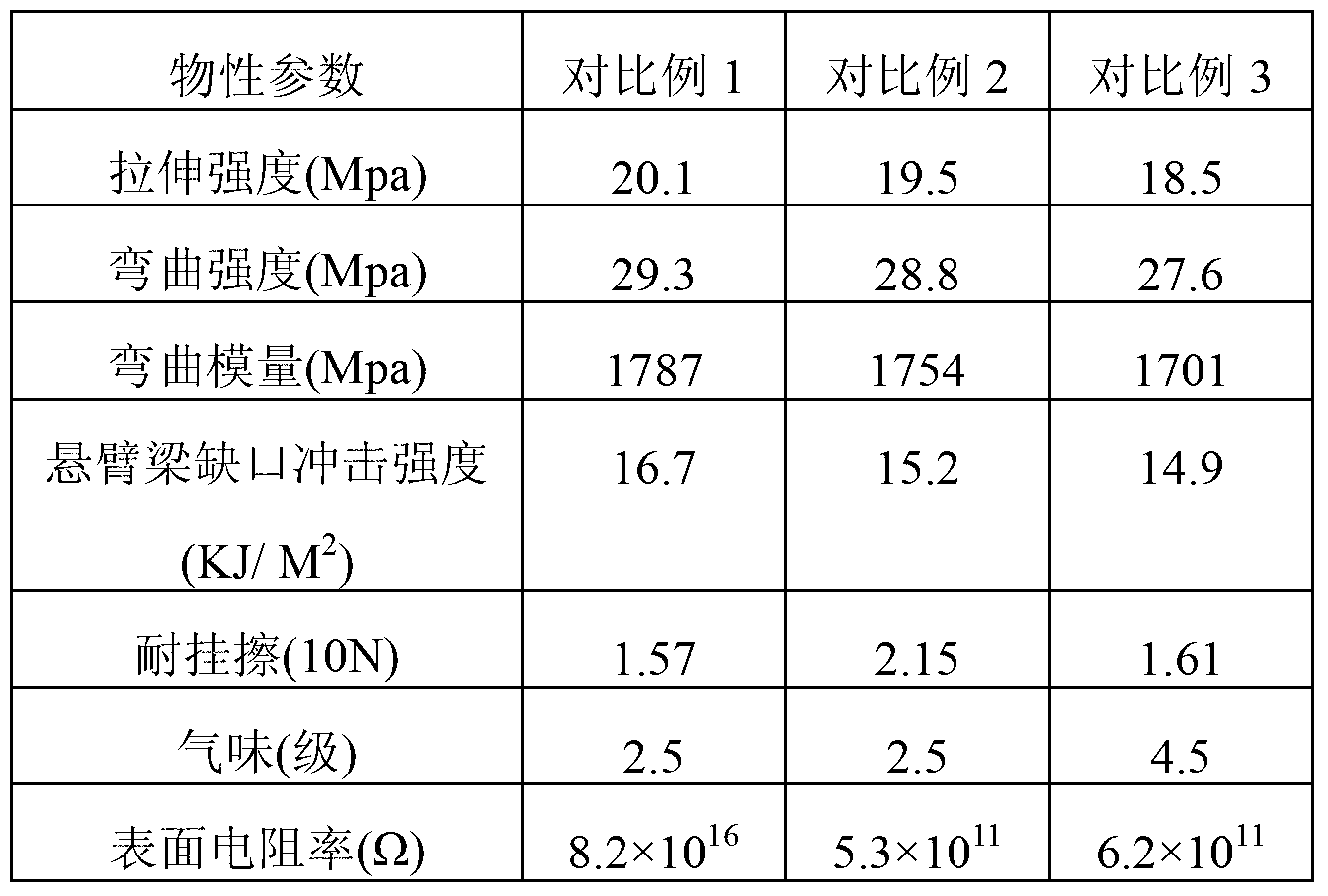

Examples

Embodiment 1

[0038] The components and weight percentages of the automobile interior trim polypropylene material of the present embodiment are:

[0039] 55 parts by weight of polypropylene resin;

[0040] 20 parts by weight of filler;

[0041] 3 parts by weight of compatibilizer

[0042] Toughener 10 parts by weight;

[0043] 3 parts by weight of anti-scratch agent;

[0044] 3 parts by weight of odor adsorbent;

[0045] 5 parts by weight of antistatic agent;

[0046] 0.3 parts by weight of antioxidant; and

[0047] 0.7 parts by weight of lubricant.

[0048] Among them, the polypropylene is low-odor high-crystalline polypropylene, the filler is 2000-mesh talcum powder, the compatibilizer is low-odor maleic anhydride grafted polypropylene, the toughening agent is POE, and the scratch-resistant agent is active polysiloxane. The odor adsorbent is a composition of zeolite, molecular sieve and nano silicon oxide, and its mass ratio is 1:1:1. The antistatic agent is a polymer permanent ant...

Embodiment 2

[0051] The components and weight percentages of the automobile interior trim polypropylene material of the present embodiment are:

[0052] 50 parts by weight of polypropylene resin;

[0053] 20 parts by weight of filler;

[0054] 3 parts by weight of compatibilizer

[0055] Toughener 10 parts by weight;

[0056] 3 parts by weight of anti-scratch agent;

[0057] 3 parts by weight of odor adsorbent;

[0058] 10 parts by weight of antistatic agent;

[0059] 0.3 parts by weight of antioxidant; and

[0060] 0.7 parts by weight of lubricant.

[0061] Among them, the polypropylene is low-odor high-crystalline polypropylene, the filler is 2000-mesh talcum powder, the compatibilizer is low-odor maleic anhydride grafted polypropylene, the toughening agent is POE, and the scratch-resistant agent is active polysiloxane. The odor adsorbent is a composition of zeolite, molecular sieve and nano silicon oxide, and its mass ratio is 1:1:1. The antistatic agent is a polymer permanent an...

Embodiment 3

[0064] The components and weight percentages of the automobile interior trim polypropylene material of the present embodiment are:

[0065] 45 parts by weight of polypropylene resin;

[0066] 20 parts by weight of filler;

[0067] 3 parts by weight of compatibilizer

[0068] Toughener 10 parts by weight;

[0069] 3 parts by weight of anti-scratch agent;

[0070] 3 parts by weight of odor adsorbent;

[0071] 15 parts by weight of antistatic agent;

[0072] 0.3 parts by weight of antioxidant; and

[0073] 0.7 parts by weight of lubricant.

[0074]Among them, the polypropylene is low-odor high-crystalline polypropylene, the filler is 2000-mesh talcum powder, the compatibilizer is low-odor maleic anhydride grafted polypropylene, the toughening agent is POE, and the scratch-resistant agent is active polysiloxane. The odor adsorbent is a composition of zeolite, molecular sieve and nano silicon oxide, and its mass ratio is 1:1:1. The antistatic agent is a polymer permanent ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com