Dialkoxyl magnesium supported solid catalyst as well as preparation method and application thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

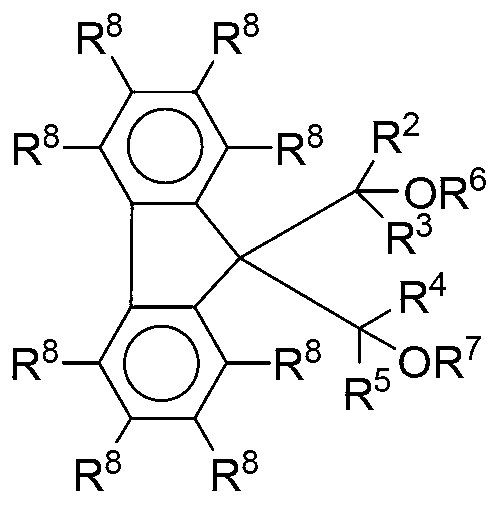

[0112] The catalyst preparation method is basically the same as that of Comparative Example 1, except that 3.5g of 9,9-bis(methoxymethyl)fluorene is used instead of dibutyl phthalate to obtain 9.5g of solid powder, which is the solid catalyst component, and the titanium content is analyzed It is 3.02 (wt)%.

[0113] The solid catalyst adopts the polymerization evaluation substantially the same as Comparative Example 1, and the difference is that methylcyclohexyldimethoxysilane (CHMDMS) hexane solution is not added, and the catalyst activity is 62,000 g polypropylene / g catalyst, and the polymer bulk density 0.42g / cm 3 .

Embodiment 2

[0115] The solid catalyst prepared in Example 1 was used to carry out polymerization evaluation, the polymerization conditions were the same as in Comparative Example 1, the catalyst activity was 60,000 g polypropylene / g catalyst, and the polymer bulk density was 0.43g / cm 3 .

Embodiment 3

[0117] The solid catalyst prepared in Example 1 was used to evaluate the polymerization. The polymerization conditions were basically the same as in Comparative Example 1, except that diisopropyldimethoxysilane (DIPDMS) was used to replace methylcyclohexyldimethoxysilane (CHMDMS). ) hexane solution, the catalyst activity is 71,000 g polypropylene / g catalyst, and the polymer bulk density is 0.42 g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com