Visual inspection and pre-warning system for longitudinal tear of conveying belt and application method of conveying belt

A technology of longitudinal tearing and visual inspection, which is applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of low reliability of actions, many intermediate links, and many times of misoperations, so as to improve accuracy and reliability, improve work efficiency, and ensure the effect of safe transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

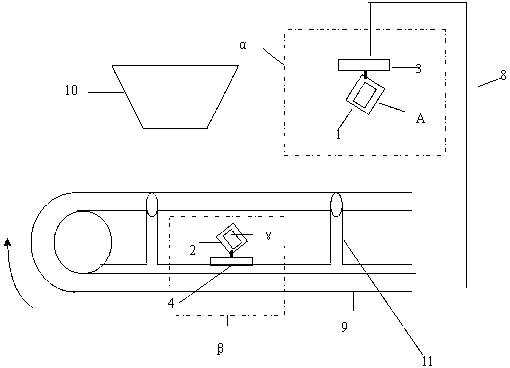

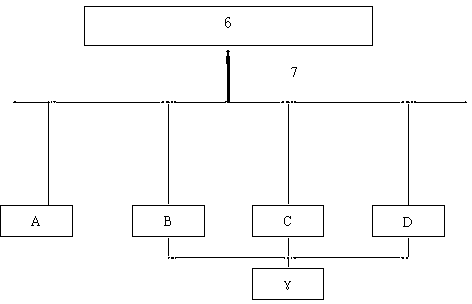

[0040] At this time, there is a source of danger, and no longitudinal tearing accident has occurred in the conveyor belt. The first infrared vision sensor A, the second infrared vision sensor B, the third infrared vision sensor C, the fourth infrared vision sensor D, and the upper explosion-proof shield 1 , lower explosion-proof shield 2, upper explosion-proof platform 3, lower explosion-proof platform 4, explosion-proof control box 5, embedded system platform 6 based on ARM architecture, CAN bus 7 and bracket 8, the first infrared vision sensor A, the second Infrared vision sensor B, the third infrared vision sensor C, and the fourth infrared vision sensor D are the same sensors, and the first infrared vision sensor A is located in the upper explosion-proof shield 1 and is connected to the embedded system platform 6 based on the ARM architecture through the CAN bus 7 , ARM-based embedded system platform 6 is composed of S3C2440, 6 USB HOSTs, SDRAM 64MB, NAND FLASH Memory 64MB, L...

Embodiment approach 2

[0055] At this time, there is no source of danger, and a longitudinal tearing accident occurs in the conveyor belt. The system for visual detection and early warning of longitudinal tearing of the conveyor belt includes: a first infrared vision sensor A, a second infrared vision sensor B, a third infrared vision sensor Sensor C, fourth infrared vision sensor D, upper explosion-proof shield 1, lower explosion-proof shield 2, upper explosion-proof pan / tilt 3, lower explosion-proof pan / tilt 4, explosion-proof control box 5, embedded system platform based on ARM architecture 6, CAN The bus 7 and the bracket 8, the first infrared vision sensor A, the second infrared vision sensor B, the third infrared vision sensor C, and the fourth infrared vision sensor D are the same sensors, and the first infrared vision sensor A is located in the upper explosion-proof shield 1 It is connected to the embedded system platform 6 based on the ARM architecture through the CAN bus 7. The embedded sys...

Embodiment approach 3

[0069] At this time, there is a source of danger, and a longitudinal tearing accident occurs in the conveyor belt. The system for visual detection and early warning of longitudinal tearing of the conveyor belt includes: a first infrared vision sensor A, a second infrared vision sensor B, and a third infrared vision sensor C. The fourth infrared vision sensor D. Upper explosion-proof shield 1, lower explosion-proof shield 2, upper explosion-proof pan / tilt 3, lower explosion-proof pan / tilt 4, explosion-proof control box 5, embedded system platform based on ARM architecture 6, CAN bus 7 and bracket 8, the first infrared vision sensor A, the second infrared vision sensor B, the third infrared vision sensor C, and the fourth infrared vision sensor D are the same sensors, and the first infrared vision sensor A is located in the upper explosion-proof shield 1 and passes through The CAN bus 7 is connected to the embedded system platform 6 based on the ARM architecture. The embedded sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com