Rotatable welding worktable

A technology of rotary welding and workbench, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., which can solve the problems of reduced welding efficiency and achieve the effects of improving reliability, improving welding efficiency, and good anti-skid performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

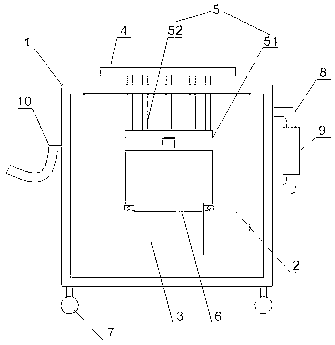

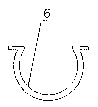

[0035] Such as figure 1 , figure 2 and image 3 As shown, the rotatable welding workbench includes a frame body 1, a welding machine fixing box 2, a motor 3, a turntable 4, a connecting device 5 and a fixing ring 6, the welding machine fixing box 2 is fixed in the frame body 1, and the fixing ring 6 is Ω type, the inner surface of the fixing ring 6 is close to the outer surface of the motor 3, the two ends of the fixing ring 6 are fixed on the welding machine fixing box 2 through bolt connection, and the output shaft of the motor 3 is connected with the turntable 4 through the connecting device 5.

[0036] The welder fixing box 2 is used to accommodate the welder. When working, the workpiece to be welded is placed on the turntable 4, and the motor 3 drives the turntable 4 to rotate, so that the staff can complete the welding of the welds on different positions on the workpiece without moving the position, which can effectively improve the welding efficiency .

[0037] The...

Embodiment 2

[0039] Such as figure 1 As shown, in this embodiment, on the basis of Embodiment 1, the connecting device 5 includes a bottom plate 51 and a connecting post 52, the bottom surface of the bottom plate 51 is connected to the output shaft of the motor 3, and the connecting post 52 is evenly arranged on the bottom of the bottom plate 51. On the upper surface, the connecting column 52 is connected with the bottom surface of the turntable 4 .

[0040] Connecting the turntable 4 and the motor 3 through the connecting device 5 of the above structure can make the turntable 4 receive a uniform force and prevent the turntable 4 from overturning under the action of a heavy workpiece.

Embodiment 3

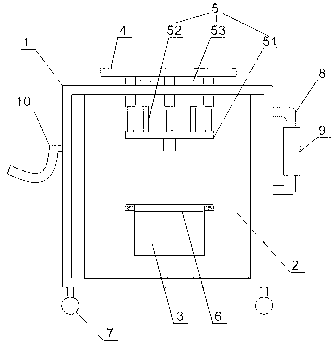

[0042] Such as figure 2 As shown, in this embodiment, on the basis of Embodiment 1, the connecting device 5 includes a bottom plate 51, a connecting column 52 and a connecting cylinder 53, the connecting cylinder 53 is evenly arranged on the bottom surface of the turntable 4, and the connecting column 52 is evenly arranged on the bottom plate 51 On the upper surface of the upper surface, the connecting column 52 is inserted into the connecting cylinder 53 , and the bottom surface of the bottom plate 51 is connected with the output shaft of the motor 3 .

[0043] The connection device 5 with the above structure is a detachable structure, which facilitates the replacement of the turntable 4 while making the turntable 4 evenly stressed. When in use, the turntable 4 can be disassembled by lifting the turntable 4, so that the turntable 4 with larger or smaller geometric dimensions can be easily replaced, so as to correspond to workpieces with different geometric dimensions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com