Novel automobile baking finish house by utilizing negative pressure and circulating air

A technology of circulating air and paint booth, which is applied in chemical instruments and methods, devices for coating liquid on the surface, and filtration of dispersed particles, etc. It can solve the problems of polluting the quality of automobile surface paint repair, leakage of harmful exhaust gas, and direct discharge of harmful exhaust gas and other problems, to achieve the effect of uniform paint quality, solve pollution problems, and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

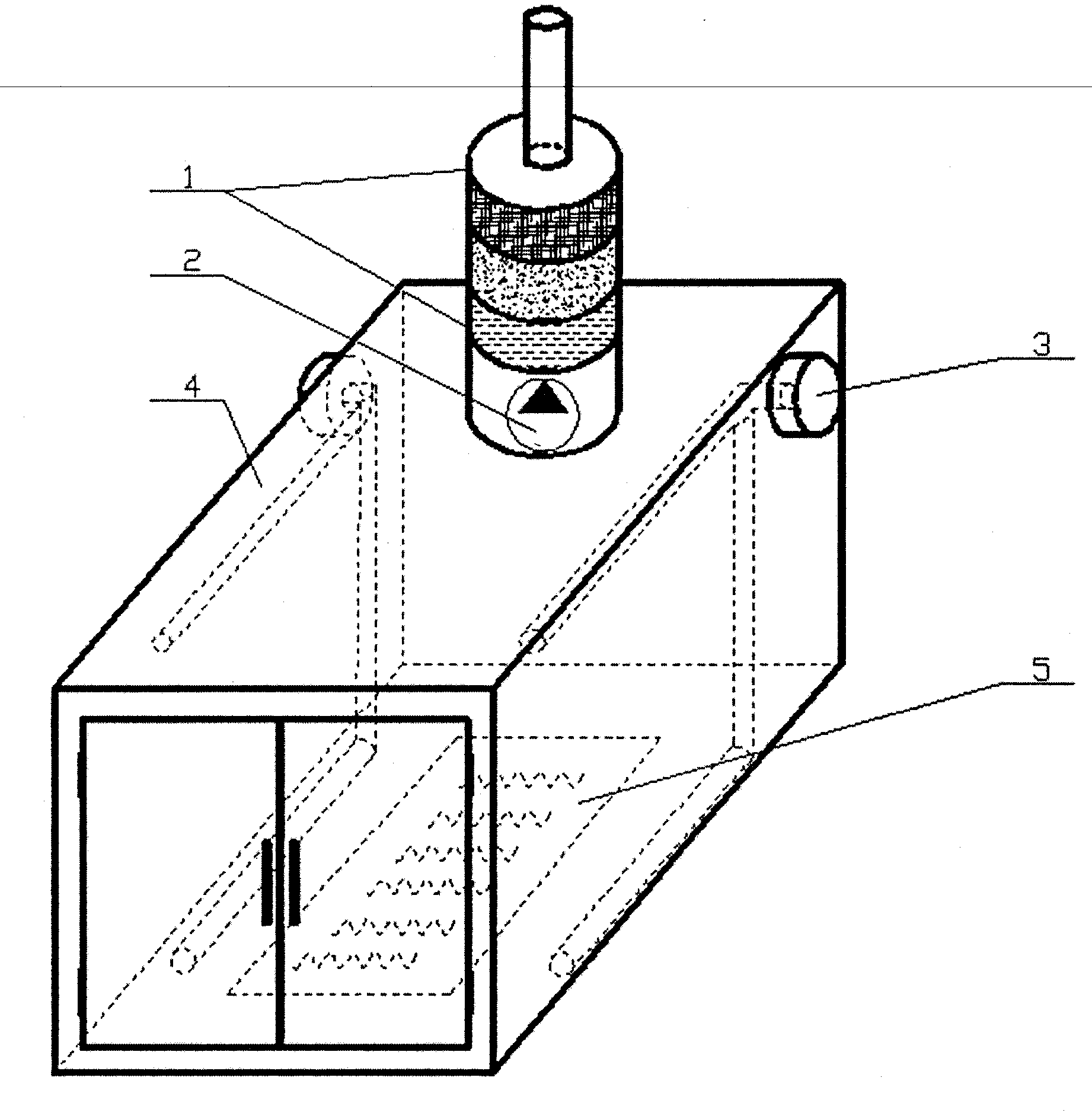

[0010] The specific working process of the novel automobile paint booth using negative pressure and circulating air will be described in detail below in conjunction with the accompanying drawings.

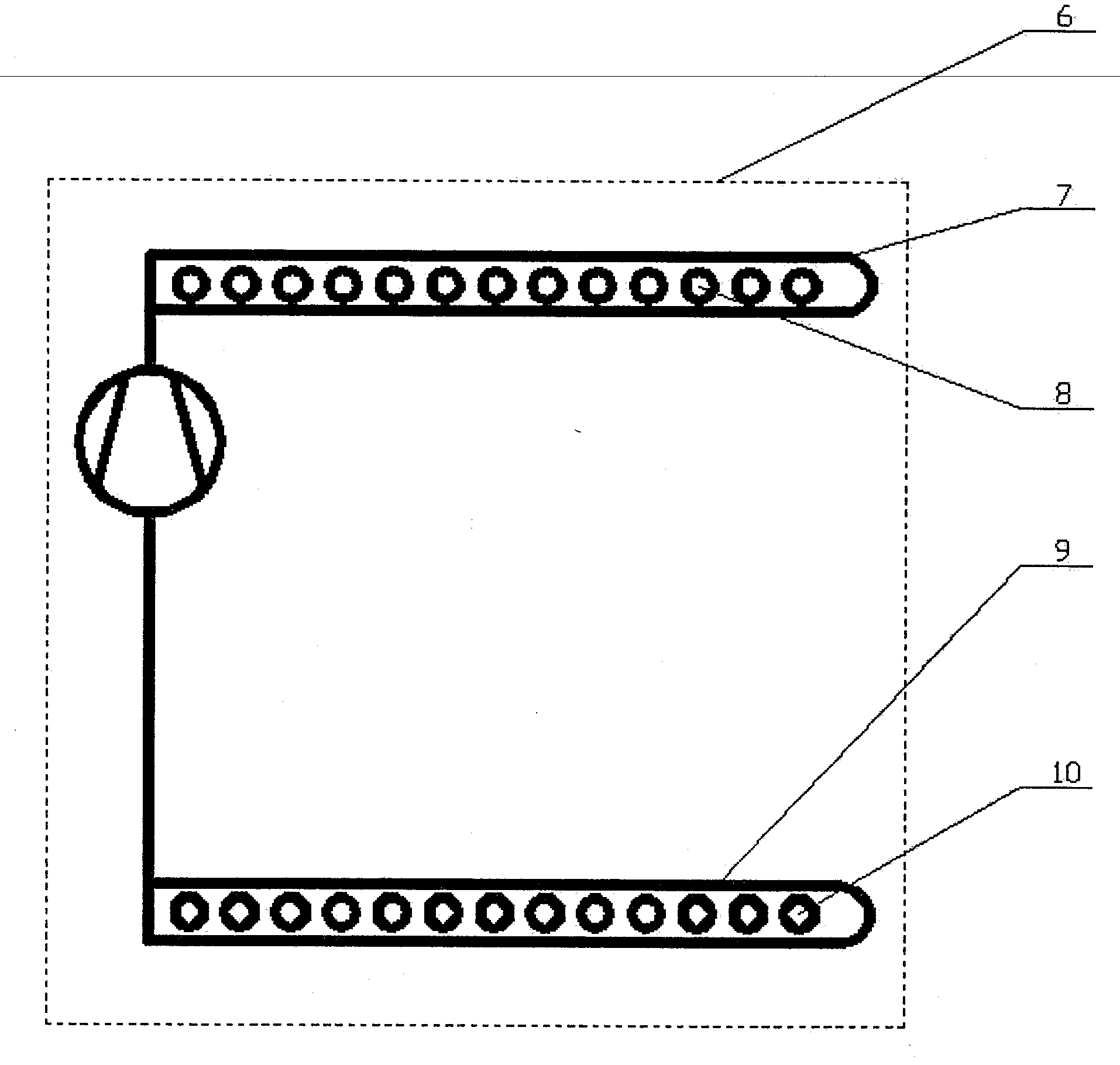

[0011] Such as figure 1 , 2. When the paint booth is working, the temperature of the lower layer in the paint booth body 4 is relatively high, and the temperature of the upper layer is relatively low. The area is heated unevenly. After the hot air circulation diffusion and convection system 6 is set, under the action of the high temperature resistant blower fan 3, the relatively low temperature gas on the upper layer of the paint booth body 4 is evenly inhaled through the air suction hole 8 of the return air exhaust pipe 7, and then the air is sent to The air jet hole 10 of the air exhaust pipe 9 is re-sent into the paint booth body 4 from the bottom of the paint booth body 4, so that the originally unevenly cold and hot gas can be effectively mixed evenly, so that the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com